Hot high-pressure hydrogen gas stripping separation method of solid-containing hydrocarbon hydrogenated products

A technology for thermal and high-pressure separation and hydrogenation products, which is applied in the preparation of liquid hydrocarbon mixtures, the distillation control/regulation of hydrocarbon oils, and the processing of tar extraction through chemical methods, etc. The capacity is poor, and the pressure-reducing valve should not use the flow channel to reduce the number of steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

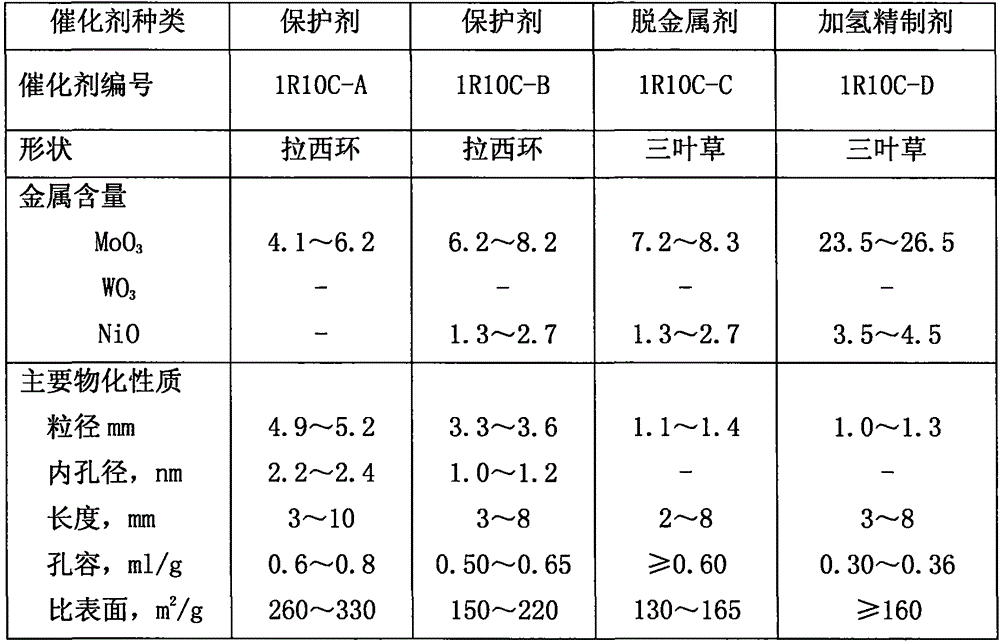

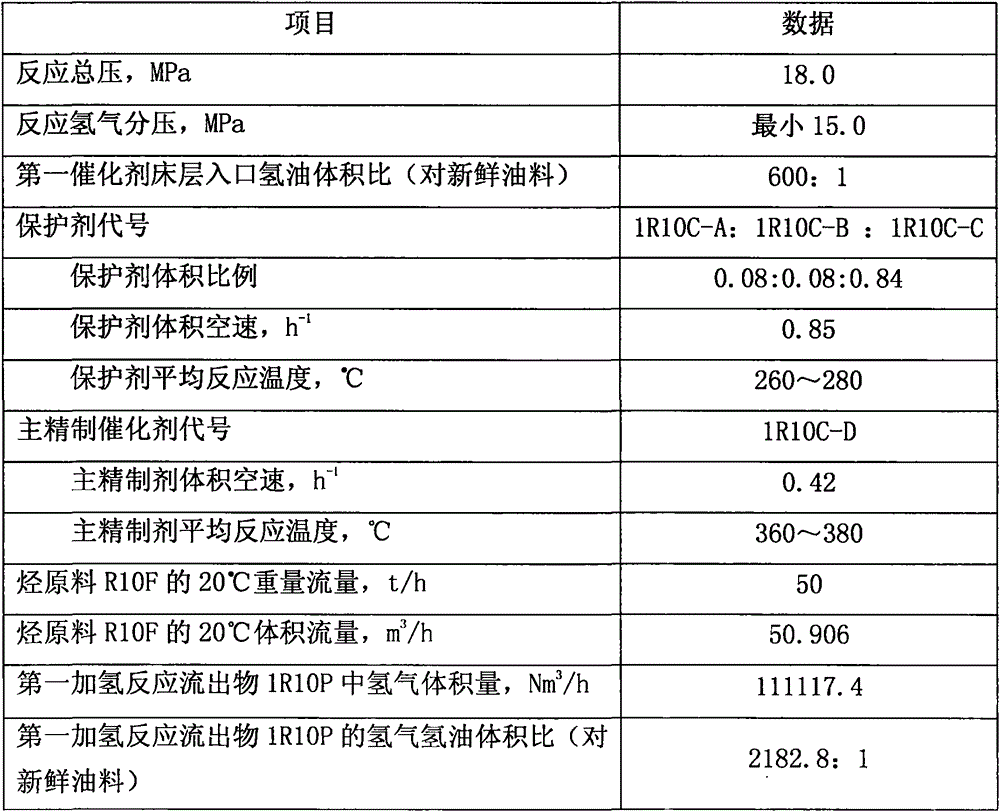

Embodiment 1

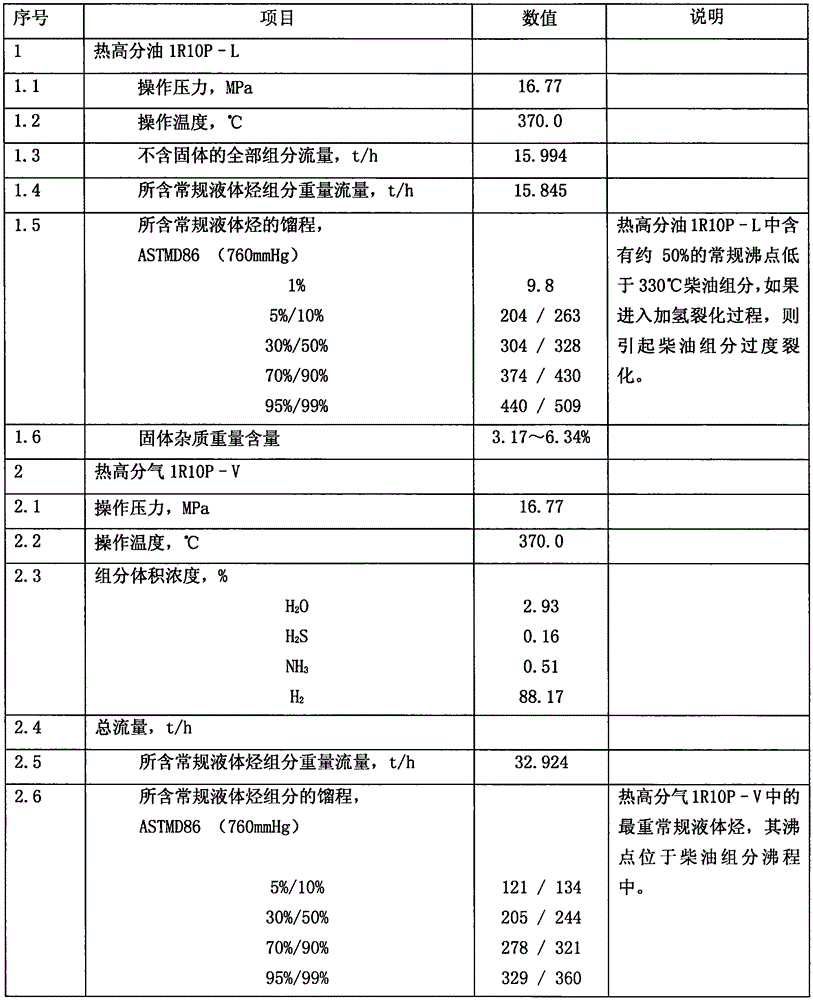

[0488] Based on the comparative example, in order to prolong the continuous operation period of the device, the thermodynamic method of the present invention is adopted to complete "gas lift and temperature drop" before the depressurization process

[0489] The gas stripping process 1HBM of the present invention is adopted to separate the diesel components in the thermal high-fraction oil 1R10P-L whose conventional boiling point is lower than 330°C, and the obtained thermal high-pressure separation and gas stripping oil 1S1L can directly enter the hydrocracking process 1S1L-HC, This simplifies the flow of the heavy components in the first hydrogenation reaction effluent 1R10P entering the hydrocracking process 1S1L-HC, and realizes substantial savings in related investment and energy consumption.

[0490] In order to optimize the operating conditions, 4 gas stripping schemes are listed for comparison and selection. The comparison conditions are: the gas hydrogen is the same, an...

Embodiment 2

[0515] Based on the scheme adopted in Example 1, that is, the scheme of 4 times of countercurrent air stripping, the oil 1S1L after hot high-pressure separation and air stripping is pressurized by a high-pressure pump, and then filtered to remove solid impurities and become desolidified oil 1S1L, and the desolidified oil 1S1L directly goes through the hydrocracking process 1S1L -HC is converted to hydrocracking reaction product 1S1L-HCP, which is mixed with the first hydrocracking reaction effluent 1R10P and recycled into the gas stripping process 1HBM, thus simplifying the hydrocracking process 1S1L-HC The process, related investment and energy consumption are greatly saved.

Embodiment 3

[0517]Based on Example 1, the gas stripping process is 4 times of countercurrent contact, the hydrogen gas stripping temperature is adjusted to 300°C, and the logistics parameters at the outlet of the pressure reducing valve are shown in Table SSL1-5 and Table SSL1-6.

[0518] Table SSL1-5 is the summary table of the air stripping results of Embodiment 3. The summary table of the air stripping results.

[0519] Table SSL1-6 is the comparison between the gas phase composition BJ03 of the final depressurized stream in Example 3 and the gas phase composition BJ01 of the final depressurized stream in the comparative example.

[0520] Compared with the control example, the gas stripping effect is that the depressurization gas phase product is reduced from 42.677kgmol / h to 14.122kgmol / h, and the reduction rate reaches 66.9%. In this way, the speed of cavitation, erosion and chemical corrosion in the depressurization process must be Significantly slow down, can significantly prolong ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com