A kind of compound enzyme assists the method for preparing sweet-scented osmanthus extract and essential oil

The technology of osmanthus extract and compound enzyme is applied in the field of development and utilization of natural active substances. The effect of improving the content, yield and quality of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

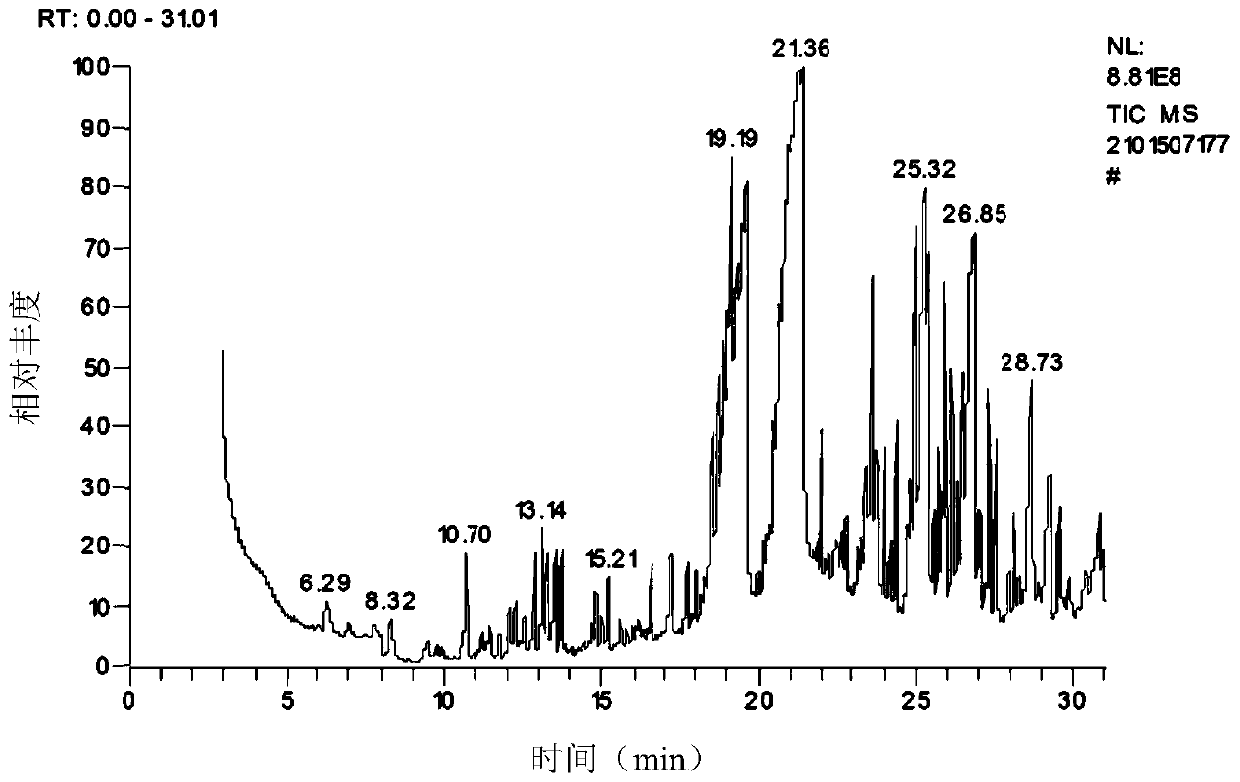

[0018] Weigh 10g of dried sweet-scented osmanthus, add pH4.5 citric acid-sodium citrate buffer solution according to the ratio of material to liquid (g / mL) 1:20, add 2.5g β-glucosidase and 2.5mg pectinase, and hydrolyze at 45°C 2.5h. After the reaction is finished, filter, dry the sample under vacuum at 50°C, and reflux extract with petroleum ether with a distillation range of 30-60°C at 40°C for 2 hours. After filtering, the filtrate was rotary evaporated and dried under vacuum at 50°C to obtain dried sweet-scented osmanthus extract. The yield of sweet-scented osmanthus extract was 3.27%. Extract the sweet-scented osmanthus extract with 200 mL of absolute ethanol at 50°C for 1 hour, then freeze the reflux at -20°C for 3 hours, filter and dry it in vacuum at 20°C to obtain the essential oil. The yield of osmanthus essential oil was 2.71%. The gas chromatography-mass spectrometer Trace DSQ was used for detection, the components of the extract were dissolved in n-hexane, and ...

Embodiment 2

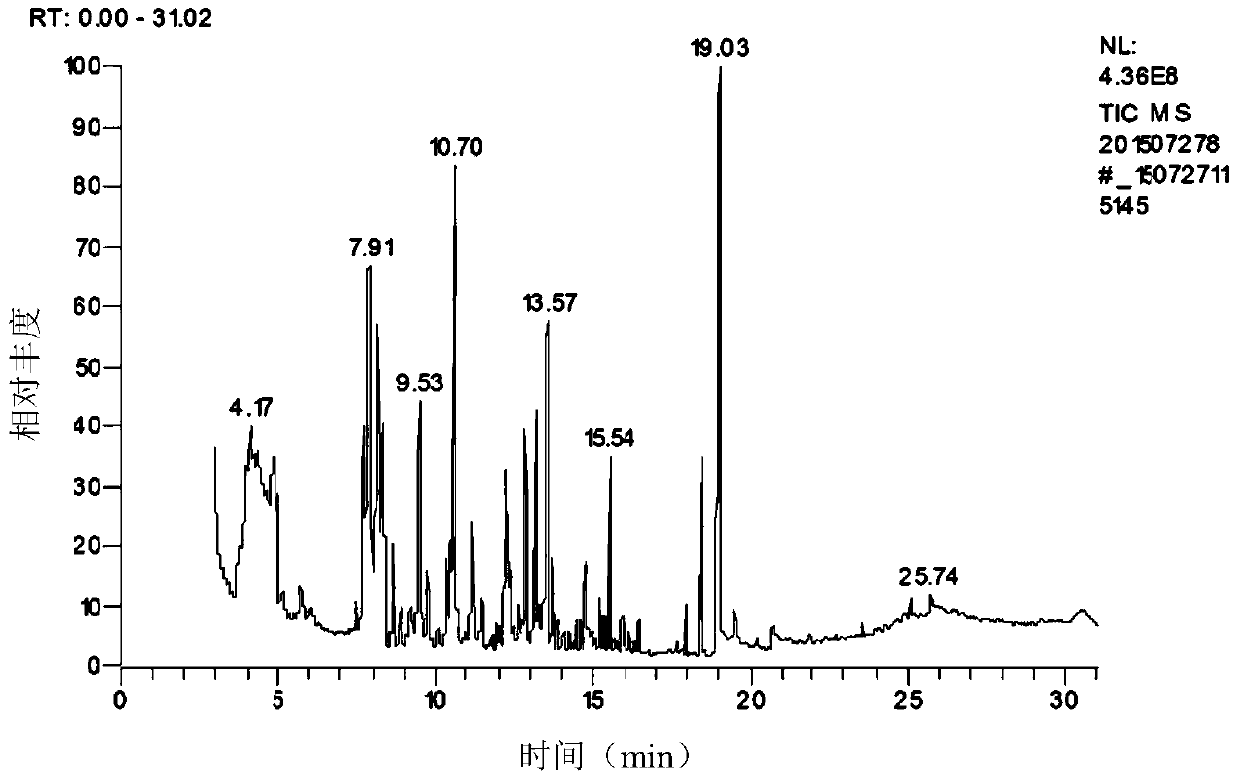

[0020] Weigh 10g of dried sweet-scented osmanthus, add pH4.5 citric acid-sodium citrate buffer solution according to the ratio of solid to liquid (g / mL) 1:20, add 5g of β-glucosidase, and hydrolyze at 45°C for 2.5h. After the reaction is finished, filter, dry the sample under vacuum at 50°C, and reflux extract with petroleum ether with a distillation range of 30-60°C at 40°C for 2 hours. After filtering, the filtrate was rotary evaporated and dried under vacuum at 50°C to obtain dried sweet-scented osmanthus extract. The yield of sweet-scented osmanthus extract was 2.55%. Extract the sweet-scented osmanthus extract with 200 mL of absolute ethanol at 50°C for 1 hour, then freeze the reflux at -20°C for 3 hours, filter and dry it in vacuum at 20°C to obtain the essential oil. The yield of essential oil was 2.12%.

Embodiment 3

[0022] Weigh 10g of dried sweet-scented osmanthus, add pH4.5 citric acid-sodium citrate buffer solution according to the ratio of solid to liquid (g / mL) 1:20, add 5mg of pectinase, and hydrolyze at 45°C for 2.5h. After the reaction is finished, filter, dry the sample under vacuum at 50°C, and reflux extract with petroleum ether with a distillation range of 30-60°C at 40°C for 2 hours. After filtering, the filtrate was rotary evaporated and dried under vacuum at 50°C to obtain dried sweet-scented osmanthus extract. The yield of sweet-scented osmanthus extract was 2.15%. Extract the sweet-scented osmanthus extract with 200 mL of absolute ethanol at 50°C for 1 hour, then freeze the reflux at -20°C for 3 hours, filter and dry it in vacuum at 20°C to obtain the essential oil. The yield of essential oil was 1.68%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com