Method for conducting composite surface modification on pure titanium

A composite surface, pure titanium technology, applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., to achieve the effect of improving mechanical properties, material grain refinement, and improving biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment relates to a method for surface modification of friction stir processing composite micro-arc oxidation, and the specific steps are as follows:

[0037] (a) Primary surface treatment of the material: the surface of a pure titanium sample with a thickness of 4 mm is polished, and cleaned with acetone to keep the surface of the sample clean.

[0038] (b) Fixing the processed sample: Fix the pure titanium sample on the fixture of the friction stir processing equipment, punch holes and lay a layer of silicon carbide (silicon carbide) particles. The hole diameter is 1mm, the depth is 2mm, and the silicon carbide particle size is 50nm.

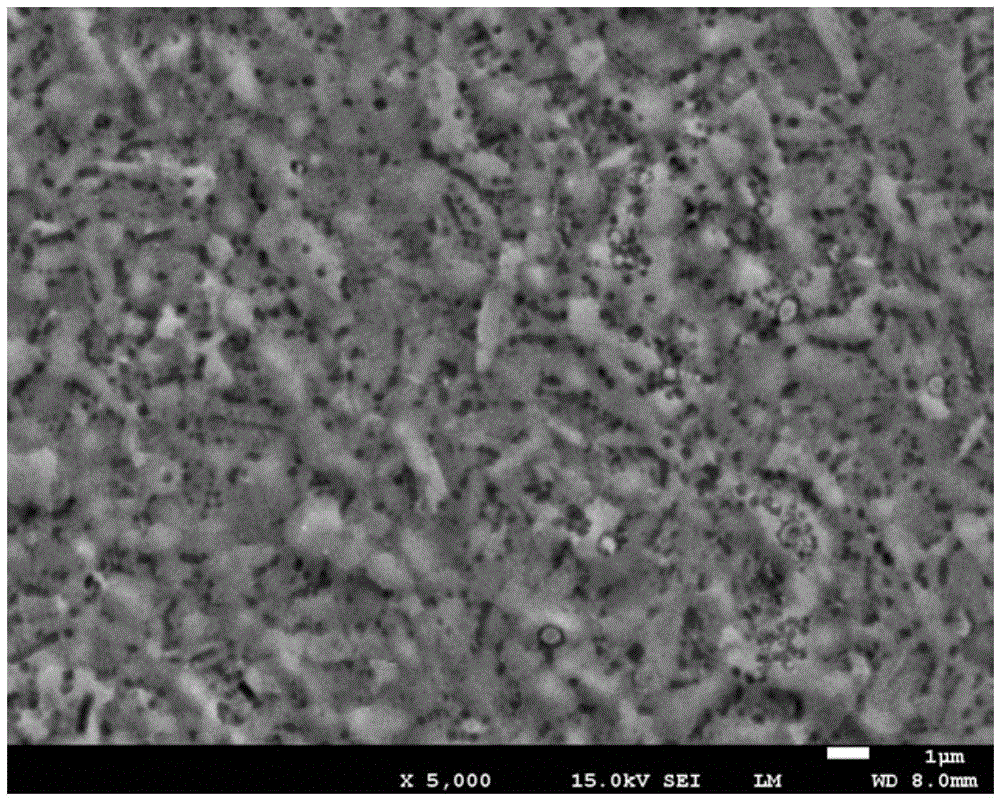

[0039] (c) Friction stir processing process: set the process parameters of friction stir processing. During processing, use a high-speed rotating stirring needle to slowly insert into the surface of the workpiece until a certain pressure is generated between the shoulder of the stirring head and the surface of the workpiece, an...

Embodiment 2

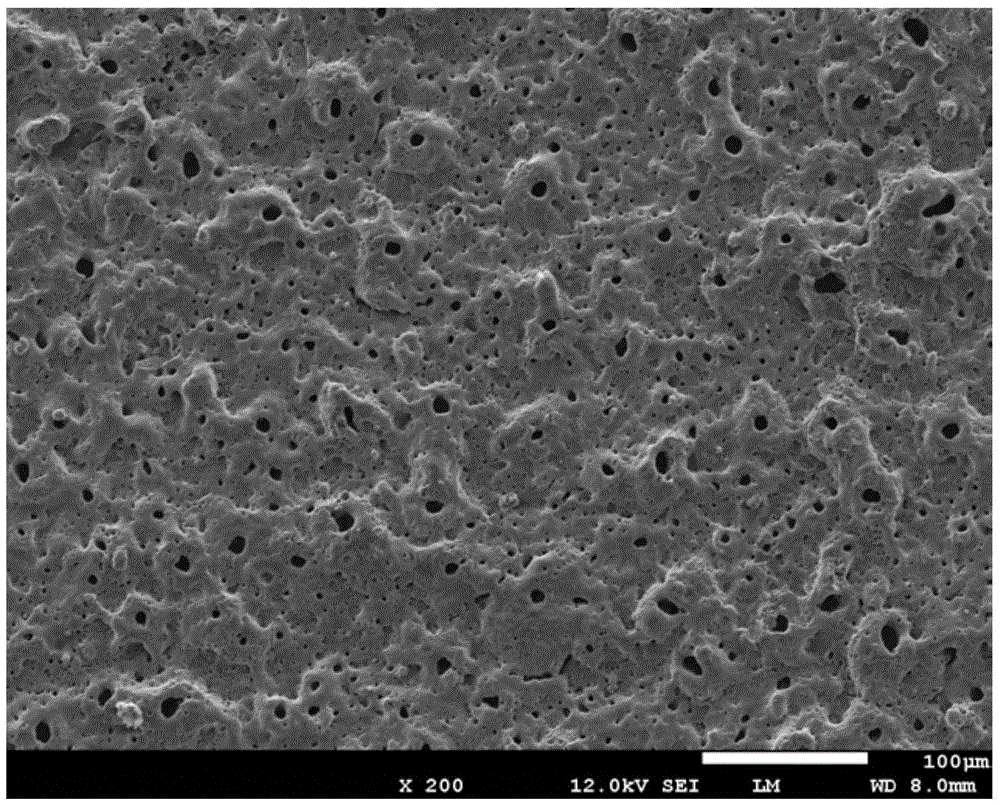

[0043] This embodiment relates to a surface modification method of friction stir processing combined with micro-arc oxidation, and the specific steps refer to embodiment 1, the difference is as follows: the duty cycle is 10%. image 3 It is the scanning electron micrograph of the surface of the sample subjected to micro-arc oxidation on the surface of the friction stir processed sample (duty ratio is 10%).

Embodiment 3

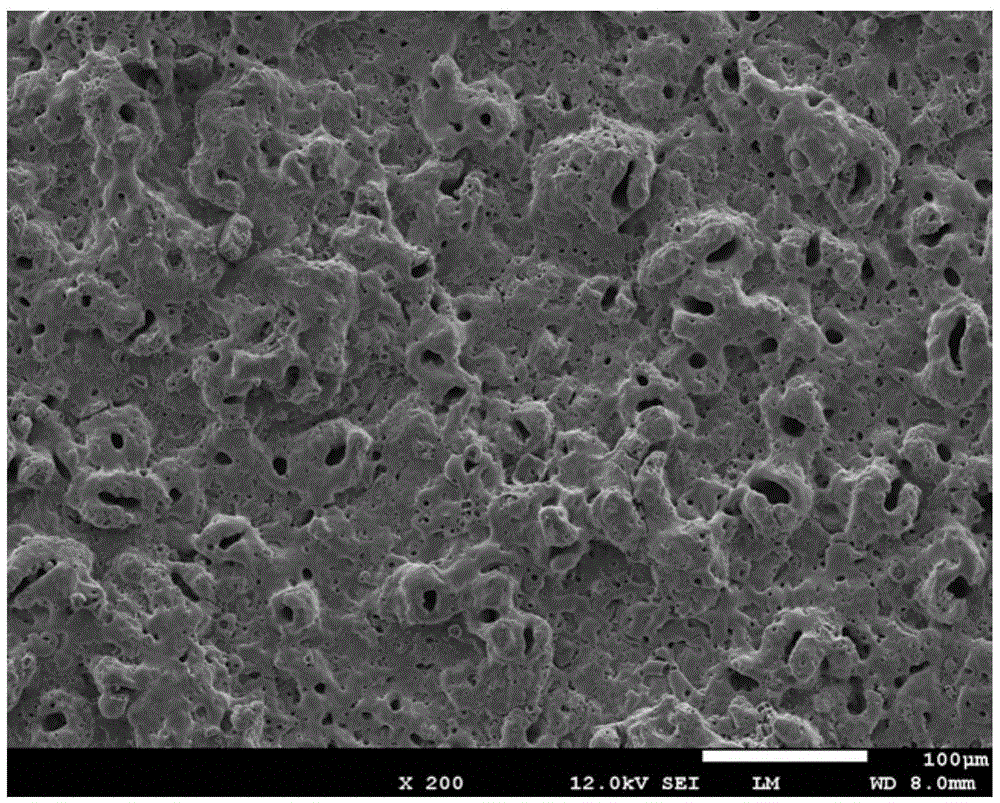

[0045] This embodiment relates to a surface modification method of friction stir processing combined with micro-arc oxidation, and the specific steps refer to embodiment 1, the difference is as follows: the duty cycle is 15%. Figure 4 It is the scanning electron micrograph of the surface of the sample subjected to micro-arc oxidation on the surface of the friction stir processed sample (duty ratio is 15%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com