Novel ammonia-nitrogen wastewater treatment material and preparation method thereof

A new technology for ammonia nitrogen wastewater, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of low removal rate of ammonia nitrogen and heavy metals, and achieve strong adsorption performance and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

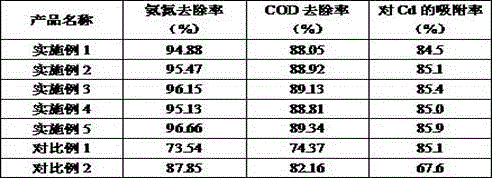

Examples

Embodiment 1

[0021] A new type of ammonia nitrogen wastewater treatment material, prepared from the following ingredients in parts by weight: 10 parts of silicon dioxide, 10 parts of titanium dioxide, 30 parts of xonotlite, 10 parts of calcium oxide, 1 part of carbonamide, tetraisobutoxy 40 parts of titanium, 0.5 parts of calcium propionate, 0.5 parts of calcium chloride, 0.1 part of propyl gallate, 200 parts of ethanol, 15 parts of anhydrous acetic acid, and 10 parts of distilled water.

[0022] The preparation method of the above-mentioned novel ammonia-nitrogen wastewater treatment material is as follows: first mix carbonamide, 50 parts of ethanol, distilled water and anhydrous acetic acid, and use a magnetic stirrer to stir for 20 minutes at a speed of 1400 rpm; mix titanium tetraisobutoxide, titanium dioxide and the remaining Mix ethanol, stir for 10 minutes at a magnetic stirrer at a speed of 600rpm, and then slowly add the solution obtained above drop by drop, while adding, stir at a...

Embodiment 2

[0024] A new type of ammonia nitrogen wastewater treatment material, prepared from the following components in parts by weight: 15 parts of silicon dioxide, 15 parts of titanium dioxide, 35 parts of xonotlite, 15 parts of calcium oxide, 1.5 parts of carbonamide, tetraisobutoxy 50 parts of titanium, 0.7 parts of calcium propionate, 0.7 parts of calcium chloride, 0.15 parts of propyl gallate, 300 parts of ethanol, 23 parts of anhydrous acetic acid, and 15 parts of distilled water.

[0025] The preparation method of the above-mentioned novel ammonia-nitrogen wastewater treatment material is as follows: first mix carbonamide, 65 parts of ethanol, distilled water and anhydrous acetic acid, and use a magnetic stirrer to stir for 25 minutes at a speed of 1450 rpm; mix titanium tetraisobutoxide, titanium dioxide and the remaining Mix ethanol, stir for 15 minutes at a magnetic stirrer at a speed of 650 rpm, and then slowly add the solution obtained above drop by drop, while adding, stir...

Embodiment 3

[0027] A new type of ammonia nitrogen wastewater treatment material, prepared from the following components in parts by weight: 20 parts of silicon dioxide, 20 parts of titanium dioxide, 40 parts of xonotlite, 20 parts of calcium oxide, 2 parts of carbonamide, tetraisobutoxy 60 parts of titanium, 1 part of calcium propionate, 1 part of calcium chloride, 0.2 parts of propyl gallate, 400 parts of ethanol, 30 parts of anhydrous acetic acid, 20 parts of distilled water.

[0028] The preparation method of the above-mentioned novel ammonia-nitrogen wastewater treatment material is as follows: first mix carbonamide, 80 parts of ethanol, distilled water and anhydrous acetic acid, and use a magnetic stirrer to stir for 30 minutes at a speed of 1500 rpm; mix titanium tetraisobutoxide, titanium dioxide and the remaining Mix ethanol, stir for 10-20 minutes at a magnetic stirrer at a speed of 700rpm, and then slowly add the solution obtained above drop by drop, while adding, stir at a speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com