Method for producing 1,3-propylene glycol from vinyl acetate

A technology of vinyl acetate and propylene glycol, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc., can solve the problems of low yield and selectivity of propylene glycol, and achieve improved activity and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

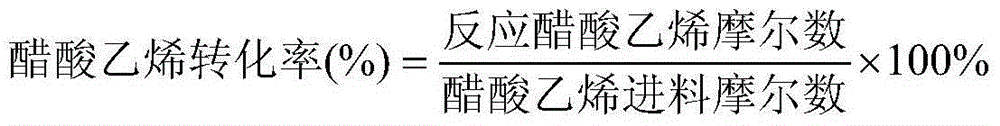

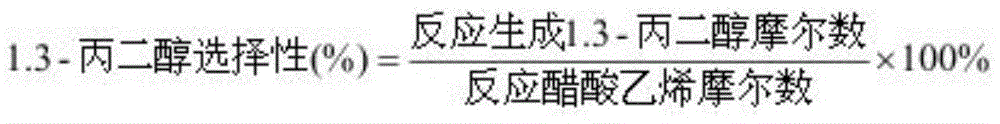

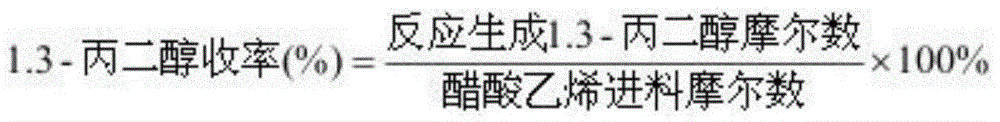

Image

Examples

Embodiment 1

[0029] The preparation of hydroformylation catalyst: the Co containing 8.60gCo, containing 1.80gSr and containing 3.00gSn 2 (CO) 8 , Sr(OA C ) 2 0.5H 2 O and triphenyltin chloride (C 18 h 15 ClSn) fully mixed and dissolved in the concentration of 10wt% acetic acid aqueous solution to obtain immersion liquid 400ml, the specific surface of 1.0L is 168m 2 / g, spherical SiO with a pore volume of 0.94 and a diameter of 5.6 mm 2 The carrier was immersed in the above impregnating solution, left to stand for 3 hours and dried at 100° C. to obtain the catalyst. The Co content of the catalyst was determined by ICP to be 8.60 g / L, the Sr content to be 1.80 g / L, and the Sn content to be 3.00 g / L.

[0030] Synthesis of 1,3-propanediol:

[0031] Step (1): Add 2.50 mol of toluene, 0.02 mol of hydroformylation main catalyst, 0.20 mol of triphenylphosphine and 1.65 mol of vinyl acetate into a 1L titanium reactor. 2.0MPa, then feed carbon monoxide and hydrogen until the pressure is 11.8M...

Embodiment 2

[0037] The preparation of hydroformylation catalyst: the Co containing 8.60gCo, containing 1.80gSr and containing 3.00gZn 2 (CO) 8 , Sr(OA C ) 2 0.5H 2 O and zinc citrate (Zn 3 (C 6 h 5 o 7 ) 2 2H 2 O) fully mixed and dissolved in the acetic acid aqueous solution with a concentration of 10wt%, to obtain 400ml of impregnation solution, and the specific surface of 1.0L was 168m 2 / g, spherical SiO with a pore volume of 0.94 and a diameter of 5.6 mm 2 The carrier was immersed in the above impregnating solution, left to stand for 3 hours and dried at 100° C. to obtain the catalyst. The Co content of the catalyst was determined by ICP to be 8.60 g / L, the Sr content to be 1.80 g / L, and the Zn content to be 3.00 g / L.

[0038] Synthesis of 1,3-propanediol:

[0039] Step (1): Add 2.50 mol of toluene, 0.02 mol of hydroformylation main catalyst, 0.20 mol of triphenylphosphine and 1.65 mol of vinyl acetate into a 1L titanium reactor. 2.0MPa, then feed carbon monoxide and hydr...

Embodiment 3

[0055] The preparation of hydroformylation catalyst: the Co(OAc) that contains 7.00gCo, contains 0.50gBe and contains 1.00gSn 2 4H 2 O, BeCl 2 and SnCl 2 2H 2 O is fully mixed and dissolved in an aqueous hydrochloric acid solution with a concentration of 8wt% to obtain 400ml of impregnation solution, and the specific surface of 1.0L is 200m 2 / g, spherical Al with a pore volume of 1.00 and a diameter of 5.6mm 2 o 3 The carrier was immersed in the above impregnating solution, left to stand for 3 hours and dried at 80° C. to obtain the catalyst. The Co content of the catalyst was determined by ICP to be 7.00 g / L, the Be content to be 0.50 g / L, and the Sn content to be 1.00 g / L.

[0056] Synthesis of 1,3-propanediol:

[0057] Step (1): Add 2.50 mol of toluene, 0.02 mol of hydroformylation main catalyst, 0.20 mol of triphenylphosphine and 1.65 mol of vinyl acetate into a 1L titanium reactor. 2.0MPa, then feed carbon monoxide and hydrogen until the pressure is 11.8MPa, incr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com