Flue gas waste heat recycling boiler with variable space and variable flow fields

A flue gas waste heat recovery boiler technology, applied in fluid heaters, preheating, liquid degassing, etc., can solve the problems of low overall system level, affecting waste heat recovery efficiency, poor performance of heat exchangers, etc., to achieve enhanced heat transfer Thermal effect, good heat transfer effect, effect of ensuring gas flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in combination with specific embodiments.

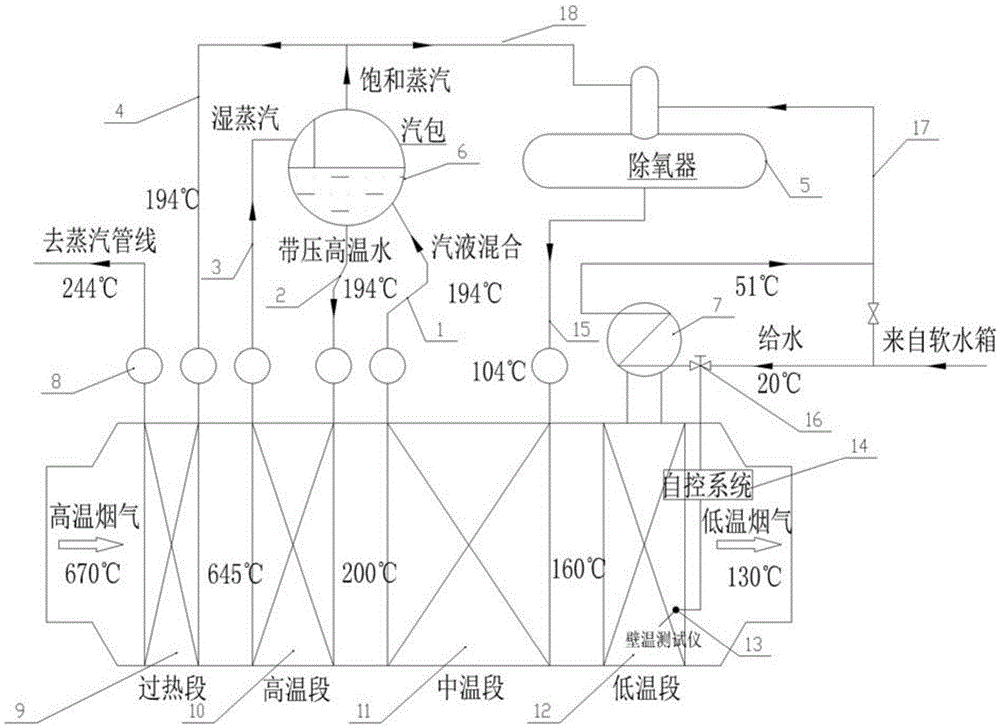

[0018] like figure 1 As shown, the flue gas waste heat boiler with variable space and variable flow field of the present invention includes an economizer outlet pipe 1, an evaporator descending pipe 2, an evaporator ascending pipe 3, a superheater inlet pipe 4, a deaerator 5, and a drum 6. Low temperature section steam drum 7, header pipe 8, superheater 9, evaporator 10, economizer 11, YHSP heat exchanger 12, wall temperature detection point 13, automatic control system 14, deaerator outlet pipe 15, automatic Control valve 16, water inlet pipe 17 of deaerator, steam inlet pipe 18 of deaerator.

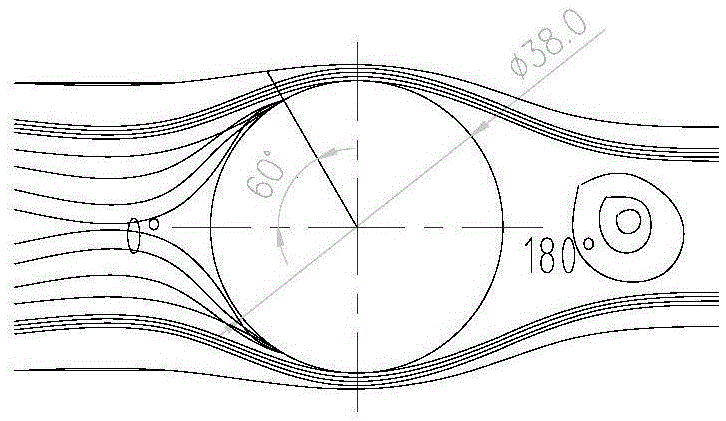

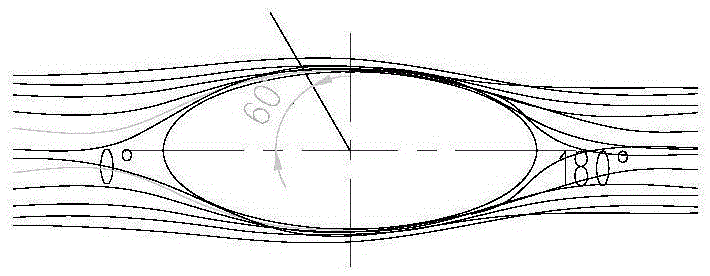

[0019] The heat carrier of this boiler is industrial flue gas, in which water / steam go through the tube side, and flue gas goes through the shell side. The boiler includes a horizontal furnace body, the furnace body from left to right is a high temperature flue gas inlet, a superh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com