A kind of strontium ferrite loaded nano-silver composite material and preparation method thereof

A strontium ferrite and composite material technology, which is applied in the field of preparation of strontium ferrite-supported nano-silver composite materials, can solve the problems of unfavorable catalyst recycling, many types of pollutants, large industrial waste water discharge, and the like, and achieves operating costs. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Take 10ml of silver nitrate solution with a concentration of 0.05mol / L, add 2ml of NaOH solution with a concentration of 0.5mol / L, and then add 1ml of ammonia water with a mass fraction of 10% after a dark brown precipitate is formed, and stir until the precipitate disappears to obtain silver ammonia solution;

[0024] (2) Add 0.3g of strontium ferrite to the silver ammonia solution, add 13ml of PVP solution with a mass fraction of 1.0% after ultrasonication for 1h, and ultrasonication for 10min to obtain solution A; Hydrazine solution was added dropwise to solution A, mechanically stirred for 2 hours, and reacted at 30°C to obtain a suspension;

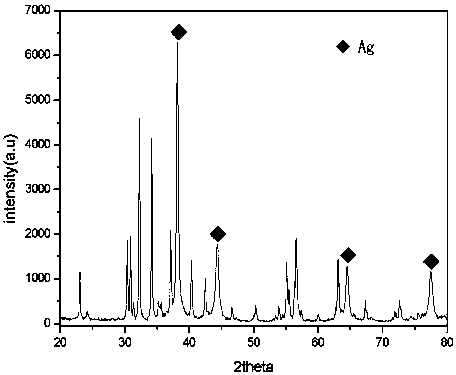

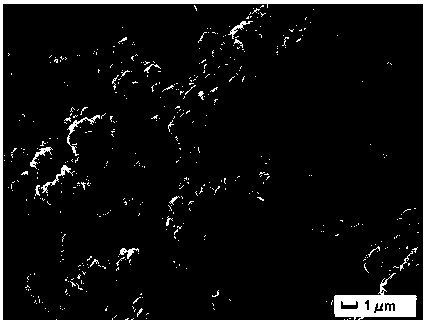

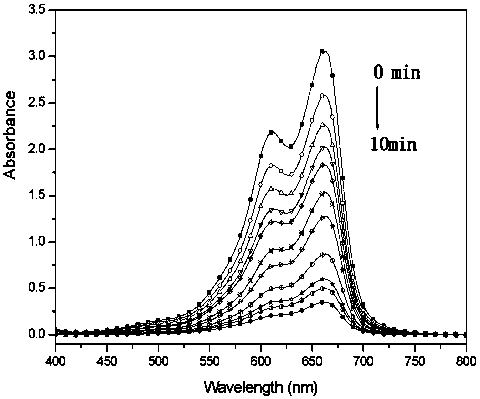

[0025] (3) Centrifuge the suspension, wash it three times with distilled water and absolute ethanol, and dry it at 45°C to obtain evenly dispersed strontium iron with a diameter of 2.50±0.5μm and a silver particle diameter of 10±0.05nm. Oxygen-supported nano-silver catalyst. The XRD of the obtained sample is as figure 1...

Embodiment 2

[0027] (1) Take 8ml of silver nitrate solution with a concentration of 1mol / L, add 1.5ml of NaOH solution with a concentration of 2mol / L, and then add 1ml of ammonia water with a mass fraction of 15% after a dark brown precipitate, stir until the precipitate disappears, and obtain a silver ammonia solution ;

[0028] (2) Add 0.3g of strontium ferrite to the silver ammonia solution, add 10ml of PVP solution with a mass fraction of 1.4% after ultrasonication for 1h, and ultrasonicate for 30min to obtain solution A; Hydrazine solution was added dropwise to solution A, mechanically stirred for 2 hours, and reacted at 60°C to obtain a suspension;

[0029] (3) Centrifuge the suspension, wash three times with distilled water and absolute ethanol, and dry at 50°C to obtain evenly dispersed strontium iron with a diameter of 1.50±0.5μm and a silver particle diameter of 20±0.05nm. Oxygen-supported nano-silver catalyst.

Embodiment 3

[0031] (1) Take 10ml of silver nitrate and silver fluoride solution with a concentration of 0.75mol / L, add 1.0ml of NaOH solution with a concentration of 1.0mol / L, and then add 1ml of ammonia water with a mass fraction of 12%, and stir until the precipitation occurs Disappeared to obtain silver ammonia solution;

[0032] (2) Add 0.4g of strontium ferrite to the silver ammonia solution, add 12ml of PVP solution with a mass fraction of 1.2% after ultrasonication for 1h, and ultrasonicate for 20min to obtain solution A; Hydrazine solution was added dropwise to solution A, mechanically stirred for 2 hours, and reacted at 45°C to obtain a suspension;

[0033] (3) Centrifuge the suspension, wash three times with distilled water and absolute ethanol, and dry at 65°C to obtain evenly dispersed strontium iron with a diameter of 2.0±0.5μm and a silver particle diameter of 15±0.05nm. Oxygen-supported nano-silver catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com