A titanium-based pore-forming agent and its application in fuel cells

A fuel cell and slurry technology that is applied to battery electrodes, circuits, electrical components, etc., to slow down the attenuation of specific capacity, improve output performance, and increase the electrochemical reaction area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

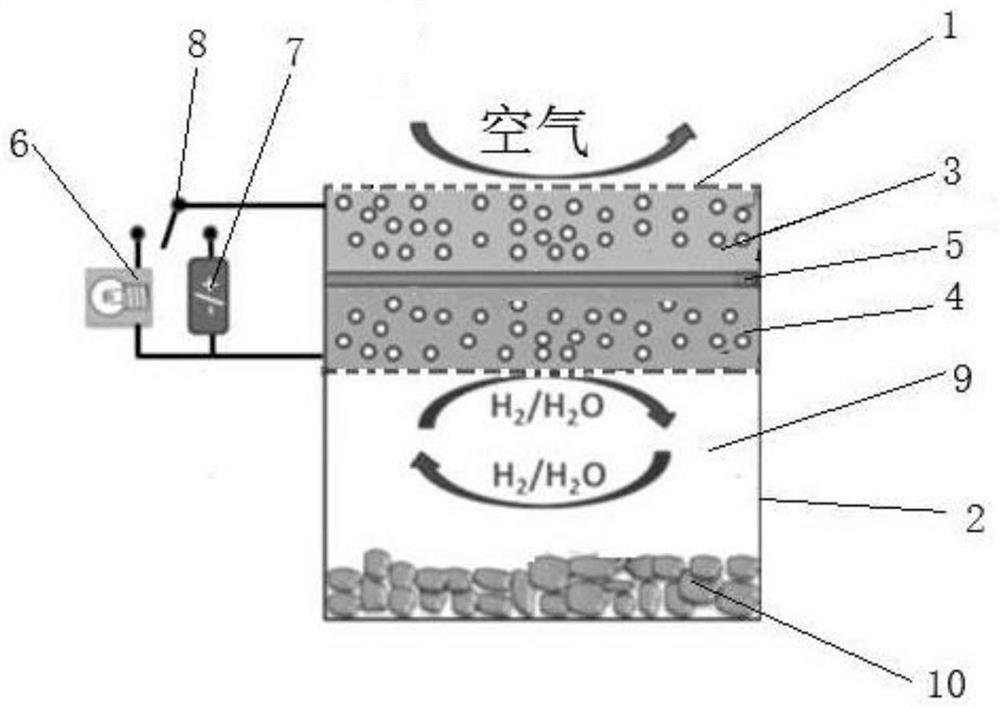

Image

Examples

Embodiment 1

[0034] Embodiment 1 (best example): the preparation method of the anode of the present invention:

[0035] S1. Preparation of anode primary powder: pre-fire the nickel-containing metal oxide powder at 600°C for 2 hours, and then mix and grind it with 8% mol YSZ electrolyte powder for 2 hours to obtain the anode primary powder, in which the nickel-containing metal oxide The mass ratio of YSZ and YSZ is 1:1; the nickel-containing metal oxide is NiO or Ni 2 o 3 one or a mixture of both;

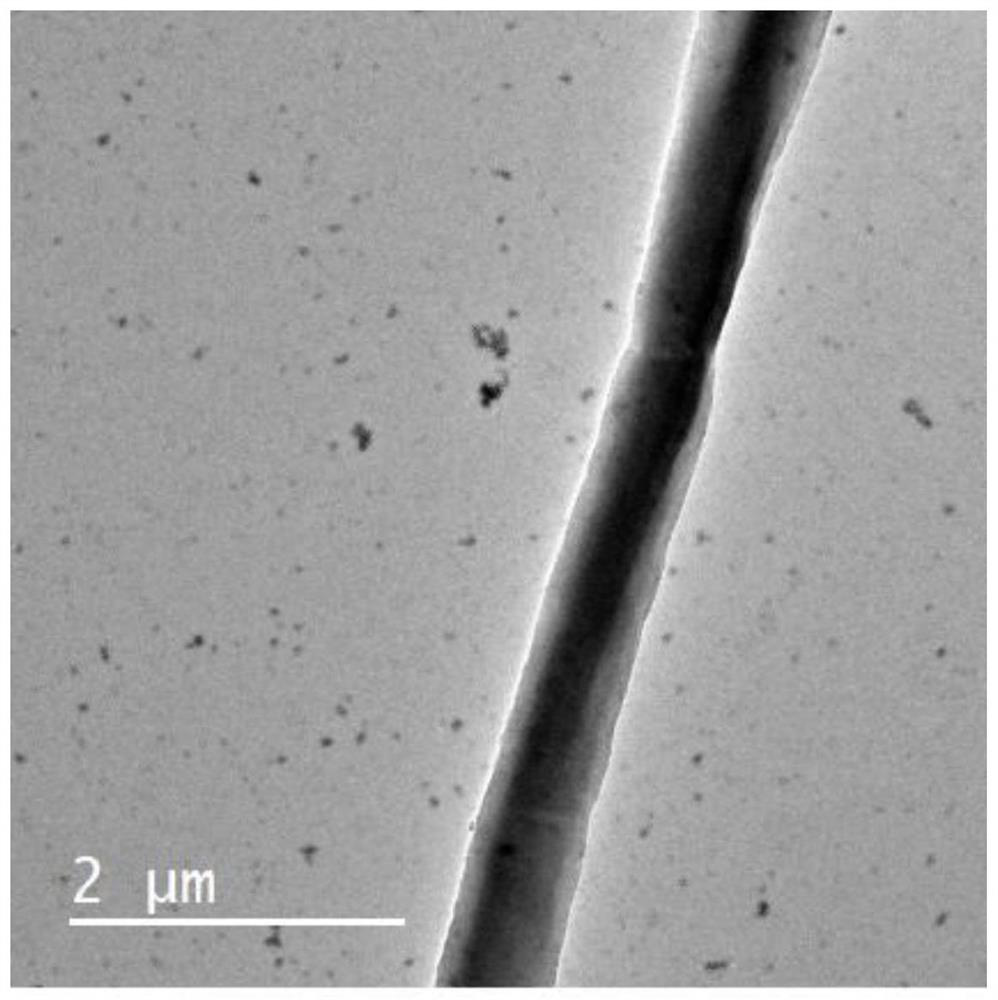

[0036] S2, preparation of TiO 2 -PAN-PVP coaxial composite fiber:

[0037] First, mix 34mL of butyl phthalate with 136mL of absolute ethanol and stir to form solution A. Then, mix 34mL of deionized water and 34mL of absolute ethanol, and add concentrated nitric acid dropwise to make the pH value 3 to form solution B. Then add solution A dropwise to the prepared solution B at 25°C, at a rate of 2 drops / second, and at the same time use a constant temperature magnetic stirrer to stir vigorously...

Embodiment 2-10

[0042] Embodiment 2-10: the preparation method of fuel cell anode of the present invention:

[0043] S1, prepare anode initial powder: same as embodiment 1;

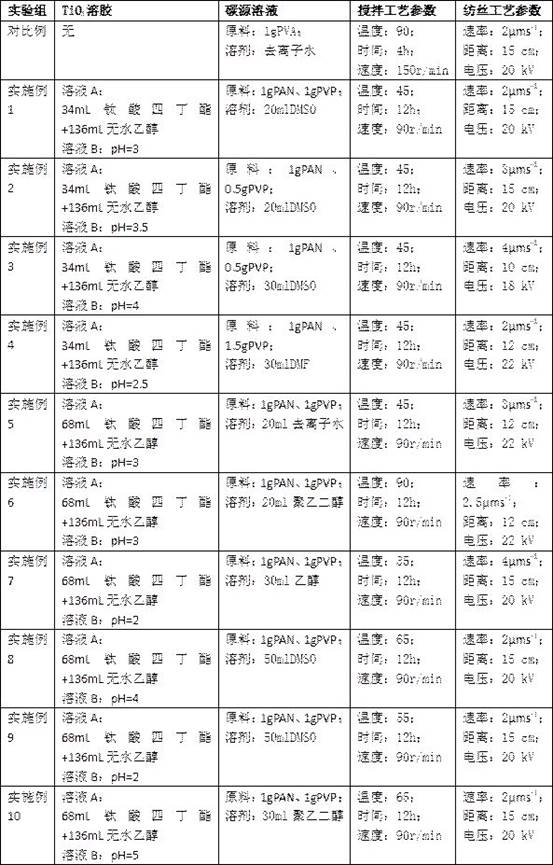

[0044] S2, preparation of TiO 2 -PAN-PVP coaxial composite fiber: the steps are the same as in Example 1, and the specific experimental parameters are designed as shown in Table 1;

[0045] S3, anode initial powder and TiO 2 -PAN-PVP coaxial composite fiber mixing: with embodiment 1;

[0046] S4, prepare anode: with embodiment 1;

[0047] Table 1 Comparison of preparation process parameters of each embodiment

[0048]

Embodiment 11

[0049] Embodiment 11 Electrochemical performance test

[0050] The anodes prepared in the above examples are used to prepare an anode coated with a solid electrolyte on one side. The method is as follows: first prepare the electrolyte slurry, and then use the slurry spin coating method to place a drop of the electrolyte slurry on the above-mentioned fuel cell anode The center of the outer surface of one side, the speed of the homogenizer is 6000r min -1 , the running time is set to 60s, and the centrifugal force generated by the high-speed rotation of the anode driven by the glue homogenizer makes the electrolyte slurry evenly coated on the outer surface of the anode side, and then the anode with a layer of electrolyte slurry is dried at 400 ° C After drying, continue to spin-coat the second layer and the third layer on the formed first layer of electrolyte film, each layer must be dried at 400 ° C, and finally the anode with a total of three layers of electrolyte film is heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com