Method for producing high-purity propofol

A production method and technology of propofol, which is applied in the field of medicine, can solve the problems of high requirements for low-temperature crystallization raw materials, long operation steps, and long processing time, so as to reduce oxidation impurities J and E, improve quality and safety, and shorten the heating time The effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

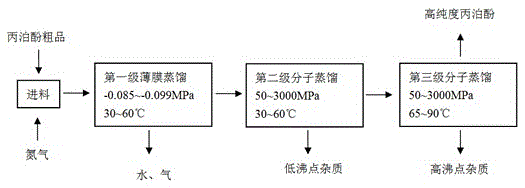

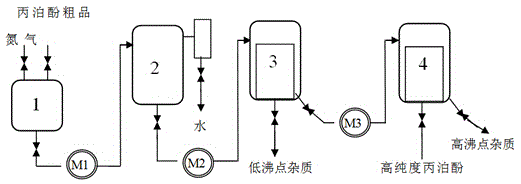

[0036]Open the nitrogen valve of the molecular distillation equipment, make the feed tank 1 replace three times with nitrogen, and put 10.0kg of the crude product of propofol produced into the feed tank 1; the crude product of propofol in the feed tank 1 is input into the The first-stage thin-film distiller 2 is controlled at a vacuum degree of -0.090MPa, the temperature is 45°C, and the feed rate is 2.0kg / h to carry out dehydration and degassing to obtain the first-stage propofol crude product; The crude product of propofol is directly input into the second-stage molecular still 3 through the pump M2, and the low-boiling impurities are separated and removed under the conditions of a vacuum degree of 1500Pa and a temperature of 45°C to obtain the crude product of the second-stage propofol; The crude phenol is directly input into the third-stage molecular still 4 through the pump M3, and the operating conditions are controlled at a vacuum degree of 1500 Pa and a temperature of 7...

Embodiment 2

[0038] Open the nitrogen valve of the molecular distillation equipment, make the feed tank 1 replace three times with nitrogen, and put 10.0kg of the crude product of propofol produced into the feed tank 1; the crude product of propofol in the feed tank 1 is input into the The first-stage thin-film distiller 2 is controlled to carry out dehydration and degassing under the conditions of vacuum degree -0.095MPa, temperature 50°C, and feed rate of 2.5kg / h to obtain the first-stage propofol crude product; The crude phenol is directly input into the second-stage molecular still 3 through the pump M2, and the low-boiling impurities are separated and removed under the conditions of a vacuum degree of 2000 Pa and a temperature of 50° C. to obtain the second-stage propofol crude product; The crude product is directly input into the third-stage molecular still 4 through the pump M3, and the operating conditions are controlled at a vacuum degree of 2000 Pa and a temperature of 80° C. to o...

Embodiment 3

[0040] Open the nitrogen valve of the molecular distillation equipment, make the feed tank 1 replace three times with nitrogen, and put 10.0kg of the crude product of propofol produced into the feed tank 1; the crude product of propofol in the feed tank 1 is input into the The first-stage thin-film distiller 2 is controlled to carry out dehydration and degassing under the conditions of vacuum degree -0.085MPa, temperature 30°C, and feed rate of 1.0kg / h to obtain the first-stage propofol crude product; The crude phenol is directly input into the second-stage molecular still 3 through the pump M2, and the low-boiling impurities are separated and removed under the conditions of a vacuum degree of 100 Pa and a temperature of 30° C. to obtain the second-stage propofol crude product; The crude product is directly input into the third-stage molecular still 4 through the pump M3, and the operating conditions are controlled at a vacuum degree of 100 Pa and a temperature of 65° C. to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com