Industrialized method for one-pot synthesis of o-chloropropene hydroxylamine

A technology of propene hydroxylamine and dichloropropene is applied in the field of industrialized synthesis of O-chloropropene hydroxylamine, which can solve the problems of increased difficulty in solvent recovery, decreased solvent recovery rate, increased cost and the like, and achieves improved reaction yield and product purity. Avoid the effect of adding and recycling separation, reducing the generation of double-joined impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

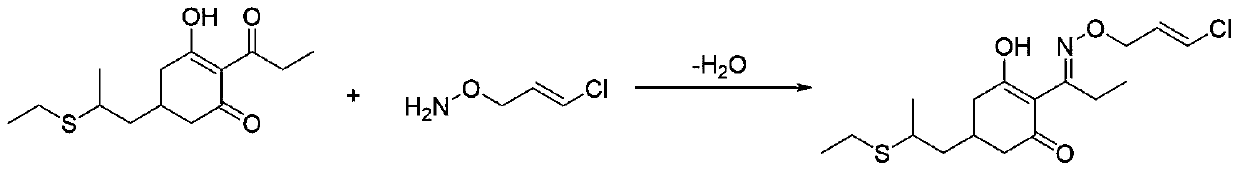

Image

Examples

Embodiment 1

[0023] Embodiment 1 prepares O-chloropropene hydroxylamine with hydroxylamine salt one-pot method:

[0024] Under the environment of feeding nitrogen, drop into the reactor 650kg of ethyl acetate (molecular weight 88, 7.4kmol), hydroxylamine hydrochloride 500kg (molecular weight 69.5, 7.2kmol), 1kg hexamethylphosphoric triamide, stir for 0.5 hour, keep The temperature of the reaction solution is that dropping the mass concentration between 20-30° C. is 1000kg (7.5kmol) of 30% sodium hydroxide solution, and after the dropping is completed, the reaction is incubated for 1 hour;

[0025] After the completion of the reaction, add 1kg polyethylene glycol 800 and 1,3-dichloropropene 820kg (molecular weight 111, 7.4kmol) in the reaction solution, dropwise mass concentration is 1000kg of 30% sodium hydroxide solution, and the control reaction solution temperature is 30-40 ℃, stirring reaction for 1.5 hours;

[0026] In the reaction solution, adding mass concentration of 30% hydrochlo...

Embodiment 2

[0027] Embodiment 2 prepares O-chloropropene hydroxylamine with hydroxylamine salt one-pot method:

[0028] Under the environment of feeding nitrogen, drop into the reactor methyl acetate 810kg (molecular weight 74, 11.0kmol), hydroxylamine hydrochloride 500kg (molecular weight 69.5, 7.2kmol), 2kg DMF, stir for 0.5 hour, keep 20-30 ℃, drip The mass concentration is 1000kg (7.5kmol) of 30% sodium hydroxide solution, and after the dripping finishes, the reaction is incubated for 1 hour;

[0029] After the reaction is completed, add 2kg triethylbenzyl amine chloride and 970kg (molecular weight 111, 8.7kmol) of 1,3-dichloropropene to the reaction solution, dropwise the mass concentration of 1000kg (7.5kmol) of 30% sodium hydroxide solution. ), and the temperature of the reaction solution was controlled at 30-40 ° C, and the reaction was stirred for 1 hour;

[0030] Adding mass concentration to the reaction solution is 1000kg (8.2kmol) of hydrochloric acid of 30%, the reaction sol...

Embodiment 3

[0031] Embodiment 3 prepares O-chloropropene hydroxylamine with hydroxylamine salt one-pot method:

[0032] Under the environment of feeding nitrogen, drop into the reactor 760kg of ethyl acetate (8.6kmol), 500kg of hydroxylamine hydrochloride (molecular weight 69.5, 7.2kmol), 1.5kg DMSO, stir for 0.5 hour, keep 20-30 ° C, dropwise add mass concentration It is 1050kg (7.9kmol) of 30% sodium hydroxide solution, after the dropwise addition, the reaction is incubated for 1 hour;

[0033] After the reaction is completed, add 1.5kg 18-crown 6 and 1,3-dichloropropene 830kg (molecular weight 111, 7.5kmol) to the reaction solution, dropwise the mass concentration of 30% sodium hydroxide solution 1050kg (7.9kmol), and The temperature of the reaction solution was controlled at 30-40°C, and the reaction was stirred for 1.5 hours;

[0034] In reaction solution, adding mass concentration is 30% hydrochloric acid 1000kg (8.2kmol), be warming up to 50-60 ℃, insulation reaction 3 hours, reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com