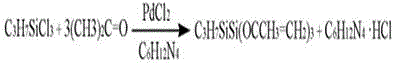

Preparation method of propyltriisoallyloxysilane

A technology of propyltriisopropenyloxysilane and propyltrichlorosilane is applied in the field of preparation of propyltriisopropenyloxysilane, and can solve the problems of long reaction time, poor filtration of triethylamine hydrochloride and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

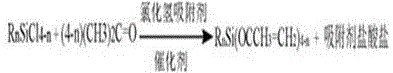

Method used

Image

Examples

Embodiment 1

[0023] Add 232g (4mol) of acetone, 0.0004g of palladium trichloride, 105g (0.75mol) of hexamethylene tetrachloride into a four-necked flask connected with magnetic stirring, spherical condenser, nitrogen gas guide tube, and constant pressure dropping funnel. Amine, 2g trimethyl orthoformate, add 177.5g (1mol) propyltrichlorosilane to the constant pressure dropping funnel, turn on the nitrogen, raise the temperature to 80°C at a stirring speed of 100 rpm, add dropwise to the constant pressure funnel The propyltrichlorosilane in the solution was added dropwise in 6 hours. After the dropwise addition of propyltrichlorosilane was completed, the temperature was maintained for 2 hours. The whole reaction was protected by nitrogen gas. The reaction pressure was normal pressure. After the reaction was completed, propyltrichlorosilane was obtained. For the crude product of acryloxysilane, the crude product of propyltriisopropenyloxysilane is cooled to below 20°C, and then under the prot...

Embodiment 2

[0025] Add 812g (14mol) of acetone, 0.003g of palladium trichloride, and 420g (3mol) of hexamethylenetetramine into a four-necked flask connected with a magnetic stirrer, a spherical condenser, a nitrogen gas guide tube, and a constant pressure dropping funnel. , 6g trimethyl orthoformate, add 710g (4mol) propyl trichlorosilane in the constant pressure dropping funnel, turn on nitrogen, heat up to 90°C at a stirring speed of 120 rpm, add dropwise the Propyl trichlorosilane, the dropwise addition of propyl trichlorosilane is completed in 6 hours. After the dropwise addition of propyl trichlorosilane is completed, keep the temperature for 2 hours. The whole reaction is protected by nitrogen gas. The reaction pressure is normal pressure. The crude propyl silane, the crude propyl triisopropenoxy silane is cooled to below 20°C, and then under the protection of nitrogen, the by-generated hexamethylenetetramine hydrochloride is removed by filtration to obtain a transparent filtrate, a...

Embodiment 3

[0027] Add 1914g (33mol) of acetone, 0.006g of palladium trichloride, 1050g (7.5mol) of hexamethylene tetrachloride into a four-necked flask connected with magnetic stirring, spherical condenser, nitrogen gas guide tube, and constant pressure dropping funnel. Amine, 18g trimethyl orthoformate, add 1775g (10mol) propyl trichlorosilane to the constant pressure dropping funnel, turn on the nitrogen gas, raise the temperature to 85°C at a stirring speed of 110 rpm, drop into the constant pressure funnel Propyltrichlorosilane, after 6 hours of dropwise addition of propyltrichlorosilane, keep the temperature for 2h reaction, the whole reaction is protected by nitrogen, the reaction pressure is normal pressure, and propyltriisopropene is obtained after the reaction is completed The crude product of oxysilane, the crude product of propyltriisopropenoxysilane is cooled to below 20°C, and then under the protection of nitrogen, the by-generated hexamethylenetetramine hydrochloride is remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com