Method for extracting cyanidin from roselle

A technology of roselle and anthocyanin is applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., to achieve the effects of simple equipment operation, high product quality and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

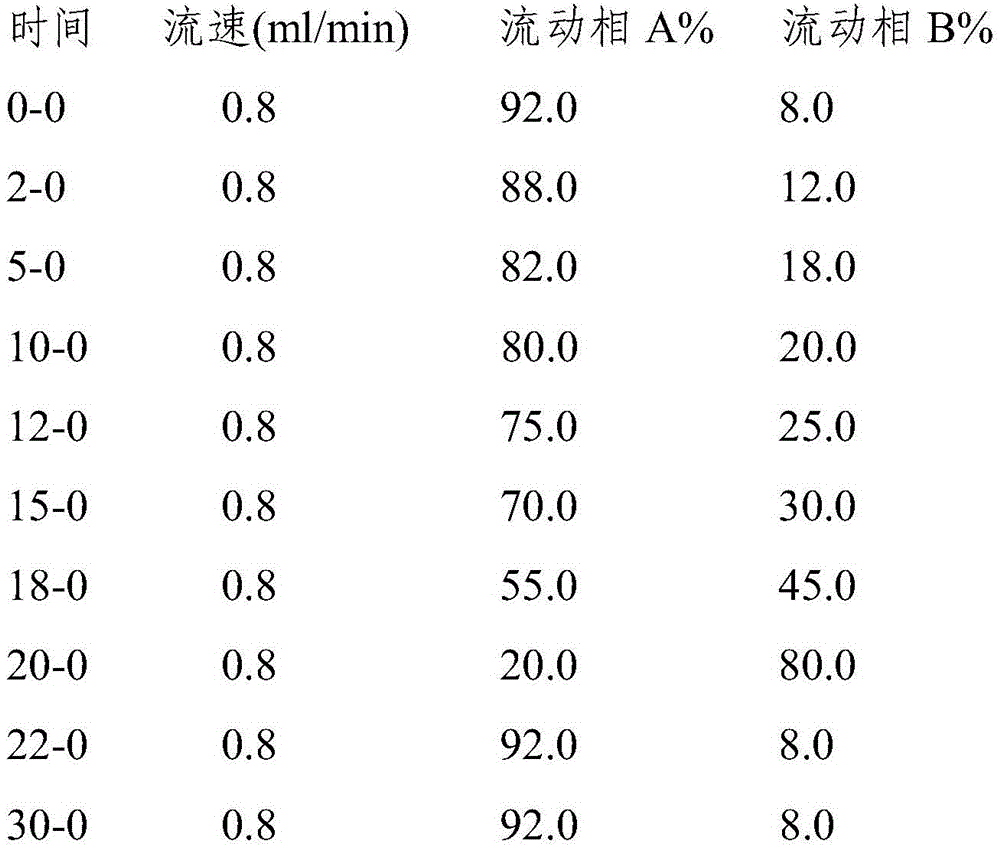

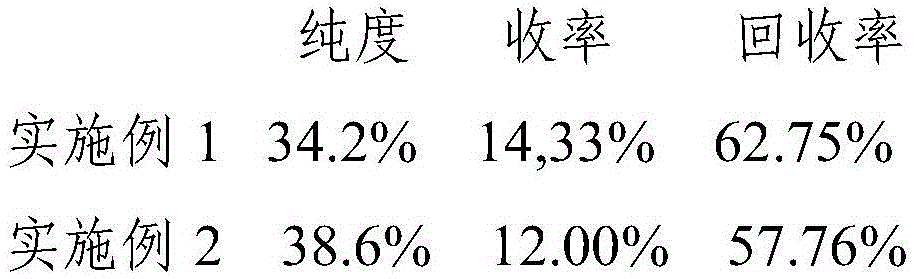

Embodiment 1

[0044] Weigh 300kg of roselle (the detected proanthocyanidin content is 7.81%), wash, dry, mechanically pulverize, and pass through a 100-mesh sieve to obtain roselle particles; add the roselle particles into the extraction tank, and add 3000L of deionized water for extraction , the extraction temperature is 50°C, and the extraction time is 8 hours; 2400L deionized water is added to the medicinal residue, the extraction temperature is 50°C, and the extraction time is 8 hours; the two extracts are combined; the extract is centrifugally filtered through a 50 μm disc centrifuge, Remove solid impurities and ash; remove macromolecular substances through 0.5-5μm hollow fiber membrane ultrafiltration, and obtain permeate with a molecular weight of less than 50,000; pass through a nanofiltration membrane with a molecular weight of 5000 to remove substances with a molecular weight greater than 5000. Obtain a permeate with a molecular weight of less than 5000; pass the permeate through a...

Embodiment 2

[0046] Weigh 400kg Roselle (proanthocyanidin content is 8.02% after detection), wash, dry, mechanically pulverize, pass through a 100 mesh sieve to obtain Roselle granules; add Roselle granules to the extraction tank, add 4000L deionized water for extraction , the extraction temperature is 45°C, and the extraction time is 12 hours; 3200L deionized water is added to the dregs, the extraction temperature is 45°C, and the extraction time is 12 hours; the two extracts are combined; the extract is centrifugally filtered through a 50 μm disc centrifuge, Remove solid impurities and ash; remove macromolecular substances through 0.5-5μm hollow fiber membrane ultrafiltration, and obtain permeate with a molecular weight of less than 50,000; pass through a nanofiltration membrane with a molecular weight of 5000 to remove substances with a molecular weight greater than 5000. Obtain a permeate with a molecular weight of less than 5000; pass the permeate through a disc-type tubular membrane, ...

Embodiment 3

[0048] Compared with Example 2, the difference is only that the steps are added: before ultrafiltration, first pass through an ultrafiltration organic membrane with a molecular weight cut-off of 100,000, discard the retentate; Filter the organic membrane interception and discard the retentate; before the disc tubular membrane filtration, the obtained permeate with a molecular weight of less than 5000 is intercepted by a disc plate membrane with a molecular weight cut-off of 200, and the retentate is retained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com