Visible-radiation-based water-soluble monomer atom transfer radical polymerization (ATRP) method

A water-soluble monomer, atom transfer technology, applied in chemical recovery and other directions, can solve the problems of restricting the large-scale application of ATRP and restricting its application, and achieve the effects of reducing metal salt residues, efficient recovery, and high catalyst recovery efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

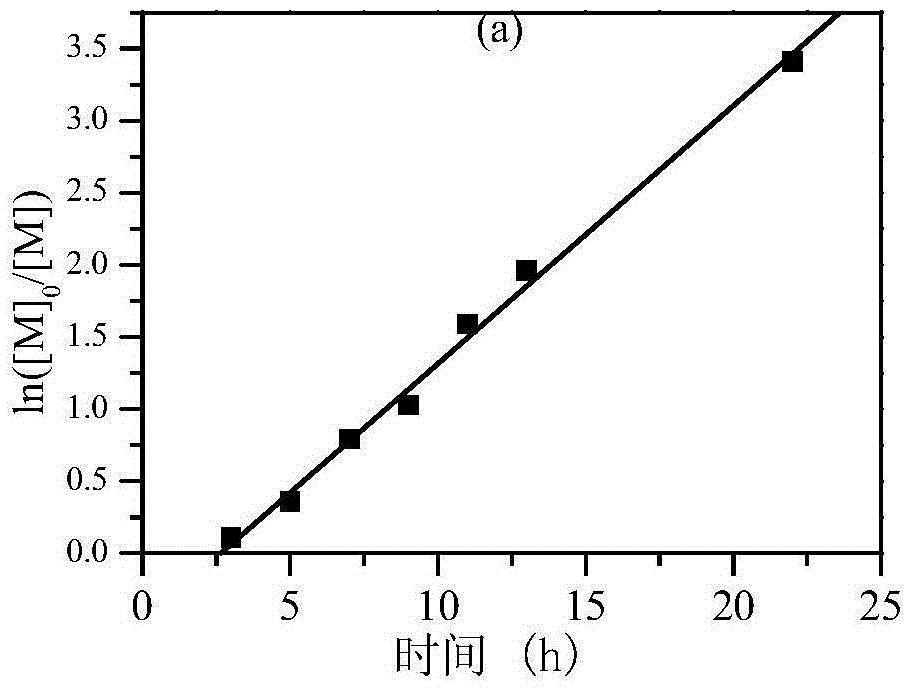

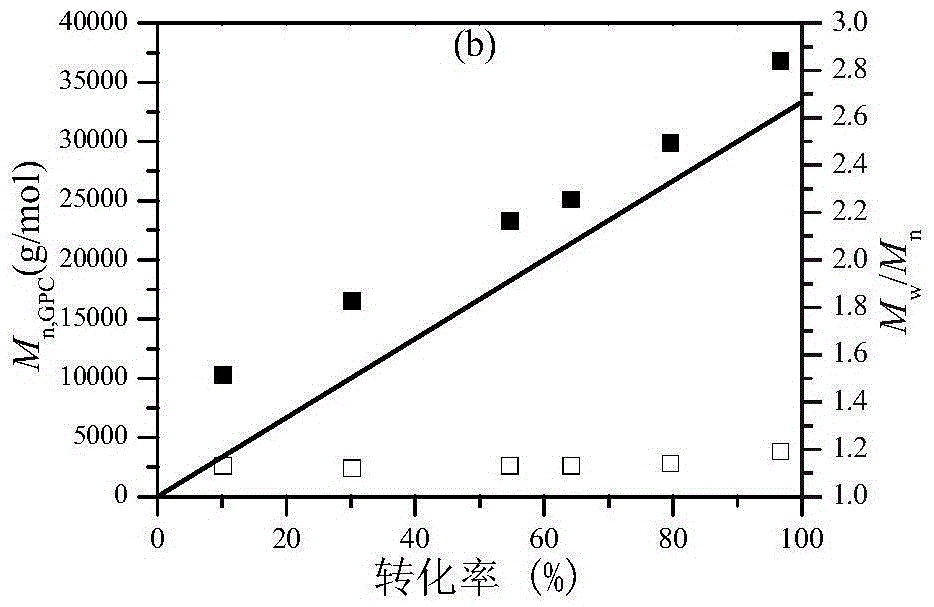

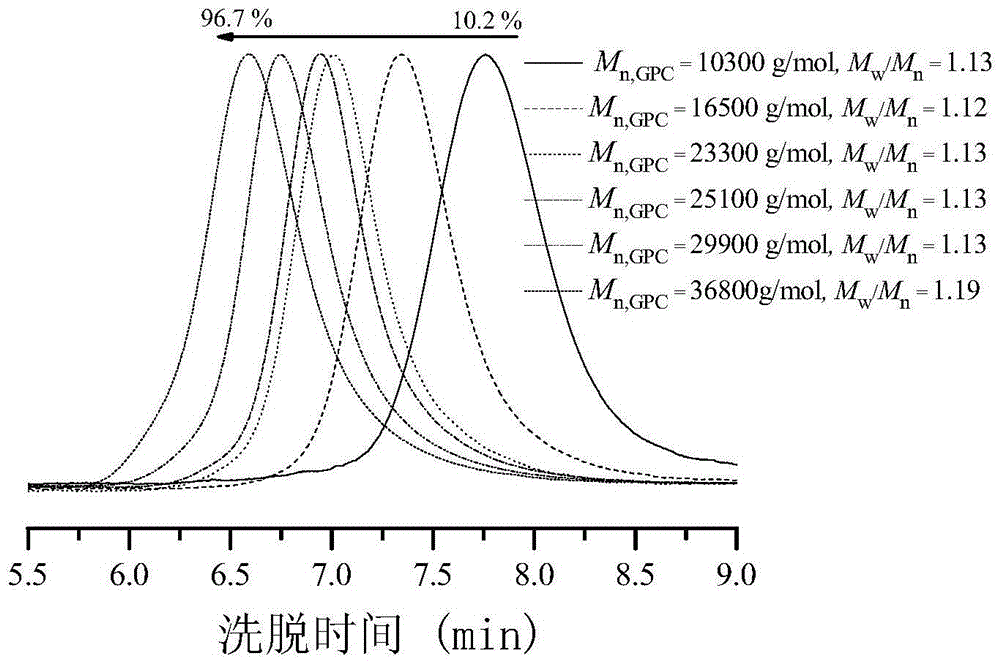

[0048] Example 1: A method for atom transfer radical polymerization of water-soluble monomers based on visible light radiation.

[0049] (1) Synthesis of catalyst / ligand complex MCc:

[0050] Water-soluble monomer mPEGMA 500 (1.0mL, 2.12mmol), initiator EBPA (10.26mg, 4.24×10 -2 mmol), catalyst Cu(DC) 2 (10.0mg, 2.12×10 -2 mmol), ligand POA-ran-P(MA-Ln) (75.7mg, 4.24×10 -2 mmol) and UV photoinitiator TPO (3.6mg, 2.12×10 -2 mmol) into a 20mL flask filled with n-heptane (4.0mL) in advance, then add absolute ethanol (3.0mL) to it, and use a high-pressure mercury with a power of 10kW under the condition of a temperature of 30°C and mechanical stirring After the lamp was irradiated for 10 h, water (0.4 mL) was added to the flask to induce the solution to separate, and the upper n-heptane phase was removed to obtain a n-heptane solution of the catalyst / ligand complex MCc. Store at 2°C until use.

[0051] (2) Polymer PmPEGMA 500 Synthesis:

[0052] Water-soluble monomer mPEG...

Embodiment 2

[0053] Example 2: Investigation of the applicability of different monomer / initiator molar ratios.

[0054] ATRP has the advantage that the molecular weight of the polymer can be designed. Therefore, according to the method described in Example 1, polymers with different molecular weights can be obtained by changing the ratio of the monomer to the initiator. The results are shown in Table 1.

[0055]

[0056] Polymerization conditions: [mPEGMA 500 ] 0 / [EBPA] 0 / [MCc] / [CQ] 0 / [TEA] 0 =100 / x / 1 / 0.5 / 1, V mPEGMA500 =0.5mL, V 正庚烷 =2.0mL, V 乙醇 =1.5mL, temperature=25°C, time=22h.

[0057] It can be seen from Table 1 that under various monomer / initiator ratios, good polymerization results can be obtained, the molecular weight distribution is narrow, the GPC molecular weight is close to the theoretical molecular weight, and the polymerization rate increases with the increase of the ratio. There is a tendency to slow down, and the polymerization system has strong applicabil...

Embodiment 3

[0058] Example 3: Investigation of the applicability of different types of water-soluble monomers.

[0059] In order to investigate the applicability of different monomers to the method recorded in Example 1, it is planned to use DMAEMA, DMAA and NIPAM three kinds of water-soluble monomers to carry out parallel control experiments to study its ATRP situation under the irradiation of white LED lamps. The results As shown in table 2.

[0060]

[0061] Aggregation conditions: V M =0.5mL, V 正庚烷 =2.0mL, V 乙醇 =1.5mL, temperature=25°C, time=22h.

[0062] It can be seen from Table 2 that four different water-soluble monomers are suitable for the n-heptane / ethanol two-phase ATRP system, but the polymerization control of methacrylate monomers is obviously better than that of acrylamide monomers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com