Method for catalyzed synthesis of hemicellulose grafted polylactic acid through organic alkali in ionic liquid

A hemicellulose and ionic liquid technology, applied in the field of biomass organic synthesis, can solve the problems of low grafting efficiency, reduced reaction efficiency, energy waste, etc., and achieve the effects of high product substitution, low reaction energy consumption, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

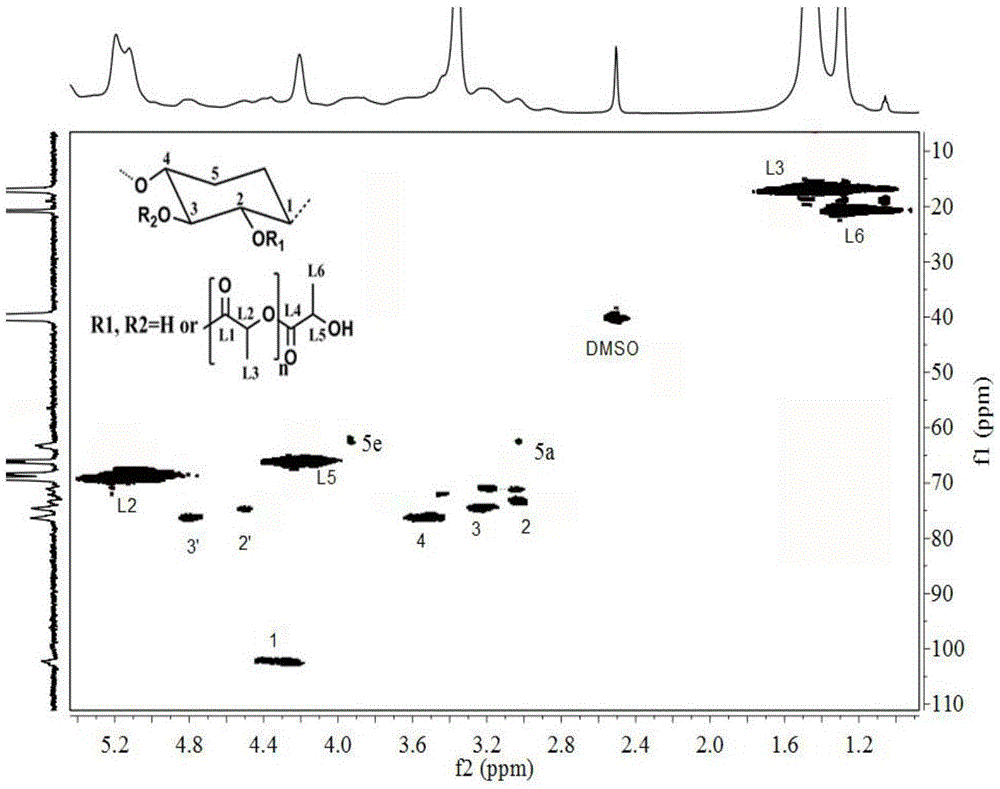

[0024] The method for synthesizing hemicellulose-grafted polylactic acid catalyzed by an organic base in a kind of ionic liquid of the present embodiment, the specific synthetic route is as follows:

[0025] (1) Under nitrogen protection, add hemicellulose (xylan mass percentage ≥ 55%) into the ionic liquid 1-allyl-3-methylimidazole chloride, dissolve at 80°C for 30 minutes to obtain hemicellulose prime solution; the mass volume ratio of hemicellulose to ionic liquid is 1:30 (g / mL); the ionic liquid is vacuum-dried at 70°C and 0.1MPa for 72h before use;

[0026] (2) Under nitrogen protection, L-lactide monomer and organic base catalyst 1,8-diazabicycloundec-7-ene are added to the hemicellulose solution in step (1), so that L -Lactide monomer undergoes ring-opening graft copolymerization reaction with hemicellulose under the action of an organic base catalyst; the reaction temperature is controlled at 50°C, and the reaction time is 12h; L-lactide monomer and hemicellulose anhyd...

Embodiment 2

[0030] The method for synthesizing hemicellulose-grafted polylactic acid catalyzed by an organic base in a kind of ionic liquid of the present embodiment, the specific synthetic route is as follows:

[0031] (1) Under nitrogen protection, add hemicellulose (xylan mass percentage ≥ 55%) into ionic liquid 1-butyl-3-methylimidazole chloride, dissolve at 80°C for 30 minutes to obtain hemicellulose Solution; the mass volume ratio of hemicellulose to ionic liquid is 1:60 (g / mL); the ionic liquid is dried at 110°C under normal pressure for 12h before use;

[0032] (2) Under nitrogen protection, L-lactide monomer and organic base catalyst 4-dimethylaminopyridine are added in the hemicellulose solution of step (1), make L-lactide monomer react in the organic base catalyst Ring-opening graft copolymerization reaction occurs with hemicellulose under the action of hemicellulose; the reaction temperature is controlled at 80°C, and the reaction time is 24h; the molar ratio of L-lactide mono...

Embodiment 3

[0036] The method for synthesizing hemicellulose-grafted polylactic acid catalyzed by an organic base in a kind of ionic liquid of the present embodiment, the specific synthetic route is as follows:

[0037] (1) Under nitrogen protection, add hemicellulose (xylan mass percentage ≥ 55%) into the ionic liquid 1-hexyl-3-methylimidazole chloride, dissolve at 80°C for 30 minutes to obtain a hemicellulose solution The mass volume ratio of hemicellulose to ionic liquid is 1:10 (g / mL); the ionic liquid is freeze-dried at -40°C for 36h before use;

[0038] (2) Under nitrogen protection, L-lactide monomer and organic base catalyst 1,5,7-triazabicyclo[4.4.0]dec-5-ene are added to the hemicellulose in step (1) In the solution, the ring-opening graft copolymerization reaction of L-lactide monomer and hemicellulose occurs under the action of an organic base catalyst; the reaction temperature is controlled at 130°C, and the reaction time is 6h; the L-lactide monomer and The molar ratio of h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com