Method for removing cobalt from polycrystalline diamond clad sheet

A polycrystalline diamond and composite sheet technology, which is applied in the field of cobalt removal from polycrystalline diamond composite sheets, can solve the problems of high sealing requirements for the substrate of the composite sheet, high volatility and corrosion of strong acids, and large irritation to operators. Achieve the effects of less corrosion, less damage to the working environment, and less destructiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Prepare a 1mol / L phosphoric acid solution, and add 10mL of 30% hydrogen peroxide solution per 100mL to prepare a decobalt acid solution.

[0037] The 1913 specification polycrystalline diamond composite sheet (Changsha Dailer New Material Technology Co., Ltd.) was used as the object of cobalt removal, and the cobalt content (mass percentage, the same below) in the polycrystalline layer of the composite sheet before decobalization was 8%. First, seal the base part of the composite sheet with tooling for anti-corrosion protection, then place the polycrystalline diamond layer of the above composite sheet in a decobalt solution and soak at 25°C for 48 hours.

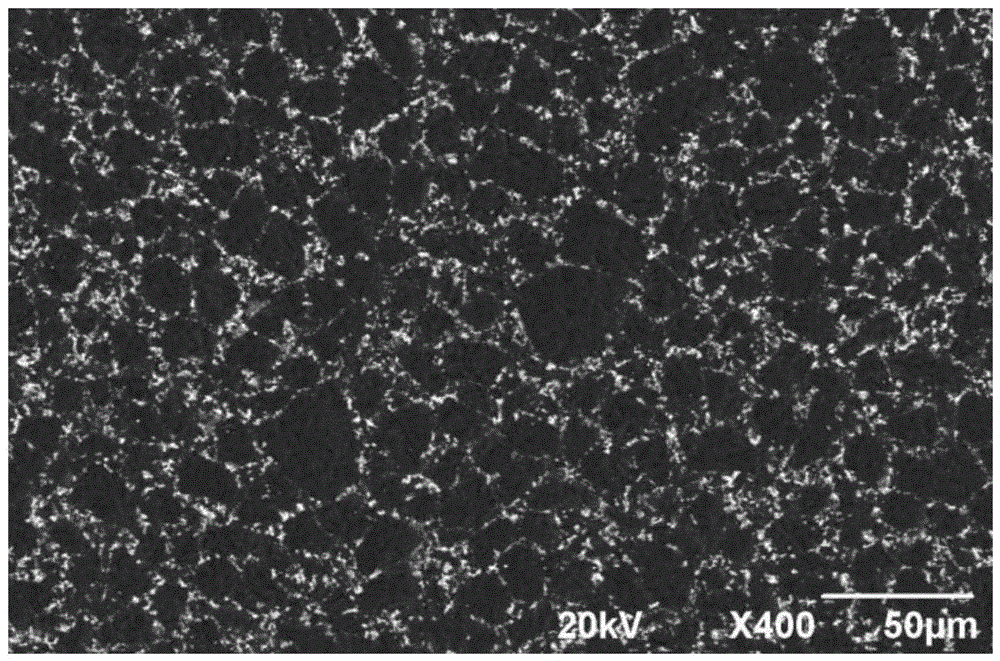

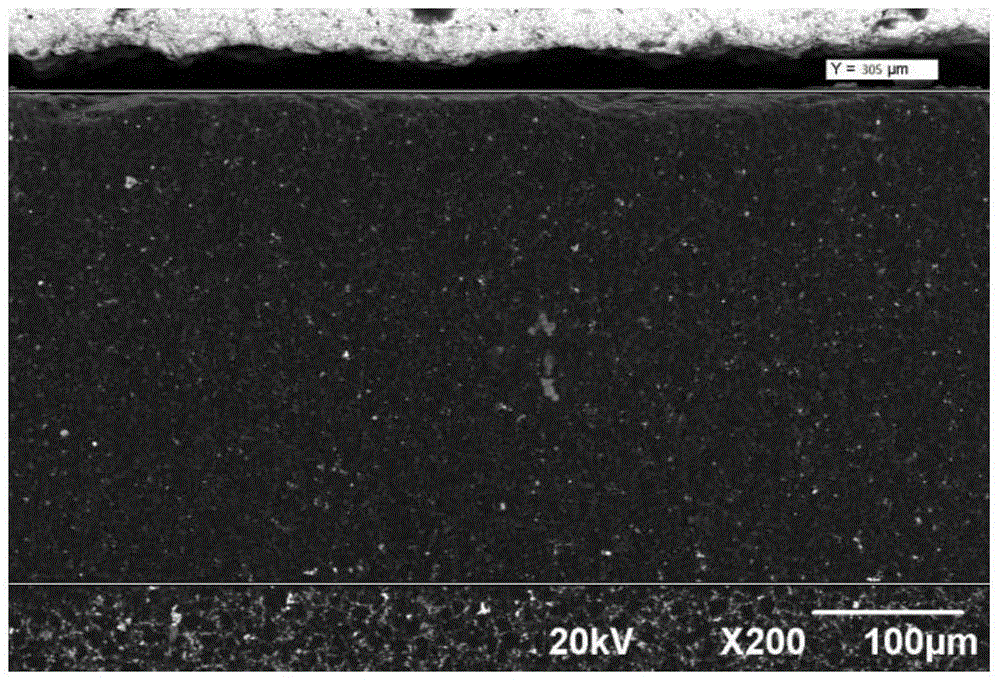

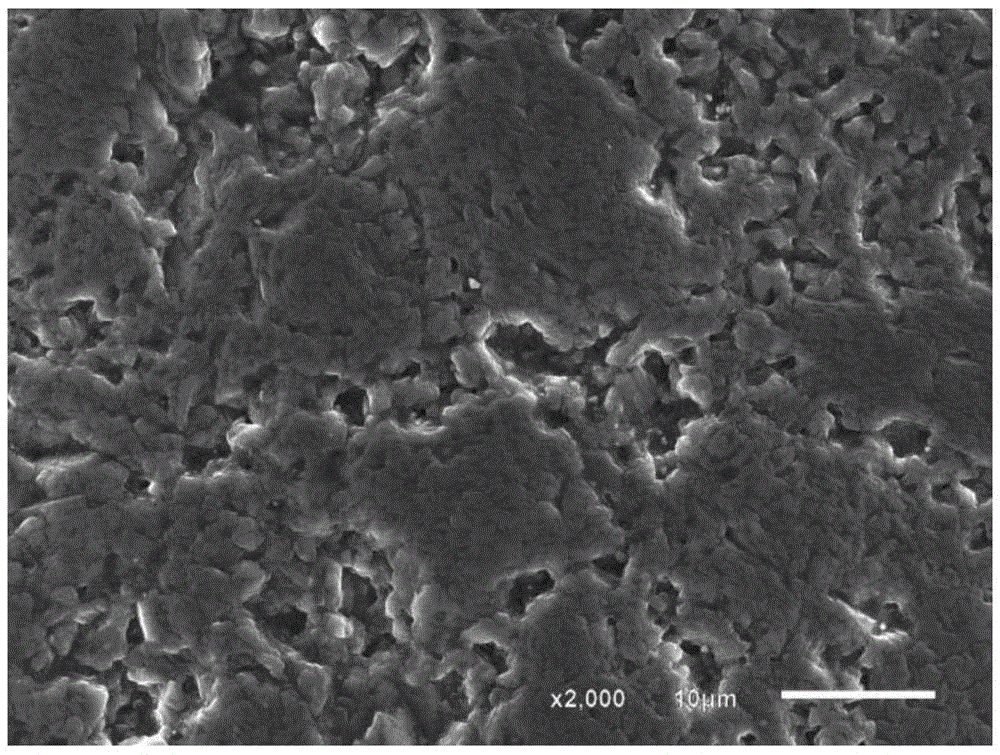

[0038] The morphology of the composite sheet before and after cobalt removal was observed by scanning electron microscope, and the cobalt removal depth was measured. See results figure 1 , figure 2 and image 3 , figure 1 It is the scanning electron micrograph of the composite sheet before the cobalt removal in E...

Embodiment 2

[0043] Prepare a 1mol / L phosphoric acid solution, and add 20mL of 30% hydrogen peroxide solution per 100mL to prepare a decobalt acid solution.

[0044] Using the same decobalt object as in Example 1, the polycrystalline diamond layer was placed in the decobalt solution and soaked at 25° C. for 48 hours.

[0045] According to the same detection method as in Example 1, the measured cobalt removal depth was 350 μm. Continue to soak for 72 hours, the cobalt removal depth is 600 μm, and the remaining cobalt content is less than 2wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com