Method for preparing petroleum ether modified polyacrylate pigment printing adhesive

A polyacrylate and polyacrylate emulsion technology, applied in dyeing, textile and papermaking, etc., can solve the problems of unsatisfactory washing fastness and hand feeling, and the effect is not excellent enough, achieve good emulsion stability, improve uniformity and Particle size, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

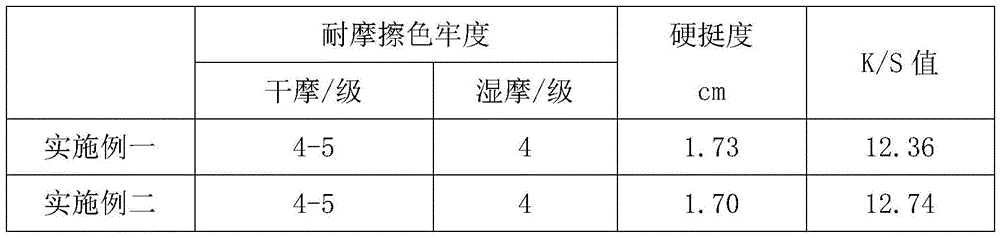

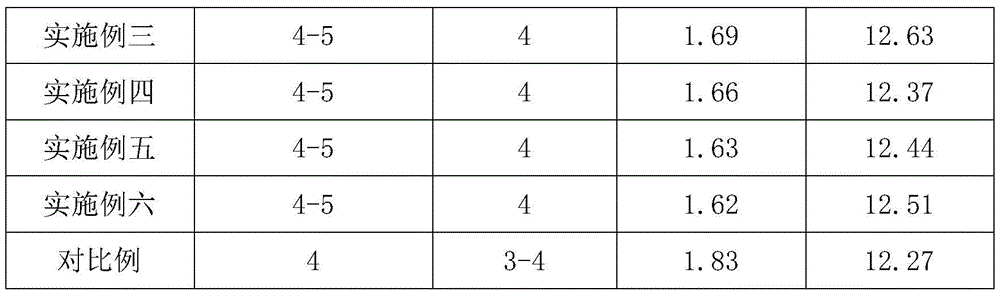

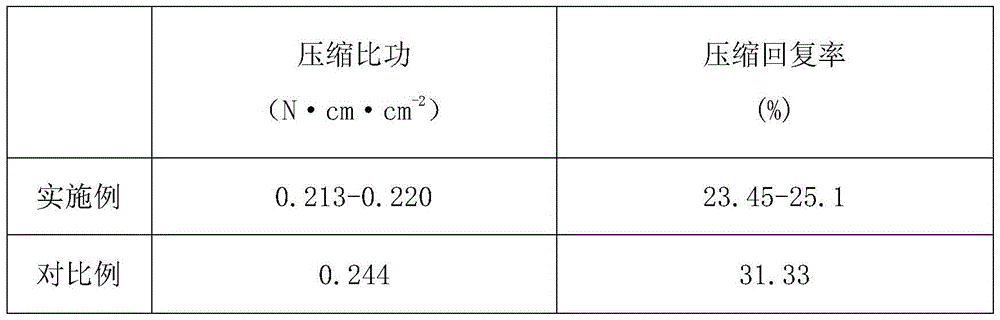

Examples

Embodiment 1

[0033] A preparation method of petroleum ether modified polyacrylate pigment printing adhesive, comprising the following steps:

[0034] The first step: the preparation of polyacrylate emulsion:

[0035] In parts by mass, dissolve 0.5 parts of acrylamide in 25 parts of deionized water and place it in a reactor at 75°C; then add emulsion A and initiator aqueous solution A, emulsion A and initiator dropwise to it The aqueous solution A is added dropwise at the same time, and the time required for the dripping is 2.5 hours, and then the emulsion B and the initiator aqueous solution B are added dropwise, and the emulsion B and the initiator aqueous solution B are added dropwise at the same time, and the required time for the dripping is 2.5 hours, after dropping, keep it warm at 60°C for 3 hours, cool down to room temperature after the reaction, adjust the pH value to 6.0, and obtain a polyacrylate emulsion;

[0036] Wherein, emulsion A is composed of 2 parts of N-methylolacrylam...

Embodiment 2

[0043] A preparation method of petroleum ether modified polyacrylate pigment printing adhesive, comprising the following steps:

[0044] The first step: the preparation of polyacrylate emulsion:

[0045] In parts by mass, dissolve 1 part of acrylamide in 40 parts of deionized water and place it in a reactor at 80°C; then add emulsion A and initiator aqueous solution A, emulsion A and initiator dropwise to it The aqueous solution A is added dropwise at the same time, and the required time for dropping is 3 hours, and then the emulsion B and the initiator aqueous solution B are added dropwise, and the emulsion B and the initiator aqueous solution B are added dropwise at the same time, and the required time for dropping is 3 hours; after dripping, keep warm at 70°C for 3 hours, cool down to room temperature after the reaction, adjust the pH value to 6.5, and obtain polyacrylate emulsion;

[0046] Among them, the emulsion A is composed of 3.5 parts of N-methylolacrylamide, 1.0 pa...

Embodiment 3

[0053] A preparation method of petroleum ether modified polyacrylate pigment printing adhesive, comprising the following steps:

[0054] The first step: the preparation of polyacrylate emulsion:

[0055] In parts by mass, dissolve 0.5 parts of acrylamide in 40 parts of deionized water and place it in a reactor at 75°C; then add emulsion A and initiator aqueous solution A, emulsion A and initiator dropwise to it The aqueous solution A is added dropwise at the same time, and the required time for dropping is 3 hours, and then the emulsion B and the initiator aqueous solution B are added dropwise, and the emulsion B and the initiator aqueous solution B are added dropwise at the same time, and the required time for dropping is 3 hours; after dripping, keep warm at 60°C for 3 hours, cool down to room temperature after the reaction, and adjust the pH value to 6.5 to obtain a polyacrylate emulsion;

[0056] Wherein, emulsion A is composed of 2 parts of N-methylol acrylamide, 1.0 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com