Structure for improving the coupling efficiency between submicron silicon waveguide and common single-mode fiber

A common single-mode optical fiber and coupling efficiency technology, which is applied in the structural field of improving the coupling efficiency of sub-micron silicon waveguides and ordinary single-mode optical fibers, can solve the problems of small coupling tolerance, difficulty in packaging with devices, and high cost, and achieve a reduction in Fresnel effect of reducing reflection loss and reducing mode mismatch loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

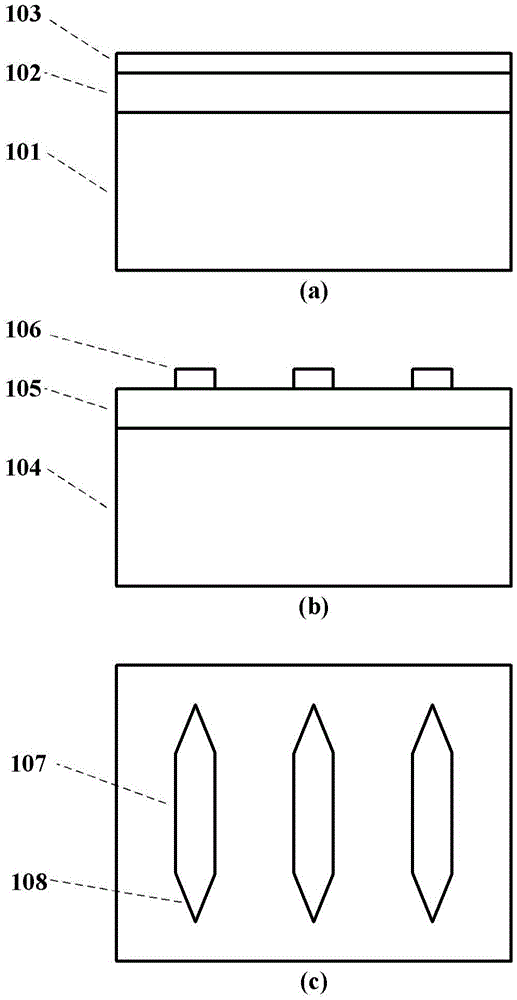

[0035] figure 1 (a) is a silicon wafer on an insulating substrate, which includes the following structures from bottom to top:

[0036] 101 is the substrate silicon structure, which is the lowermost layer of the three-layer structure of the silicon wafer on the insulating substrate. The material component is silicon, which can be pure silicon material or doped silicon material. It supports the whole The effect of wafer; 102 is the buried oxide layer structure, and it is the middle layer of the silicon wafer three-layer structure on the insulating substrate, and the buried oxide layer is doped silicon dioxide, and its material refractive index is higher than the material of pure silicon dioxide The refractive index is low, which can be achieved by doping elements such as boron or fluorine, and is used to form the lower cladding layer of the silicon dioxide waveguide; 103 is the top layer silicon structure, which is the uppermost layer of the three-layer structure of the silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com