Macromolecule polymer scaffold material preparation method based on micro-fluidic technology

A technology of high molecular polymer and scaffold material, applied in the field of preparation of high molecular polymer scaffold material, can solve the problems of uneven particle size and density distribution of porogen, difficult control, limited adjustable range of pore size, etc. The method is simple, the product is uniform, and the reproducibility is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

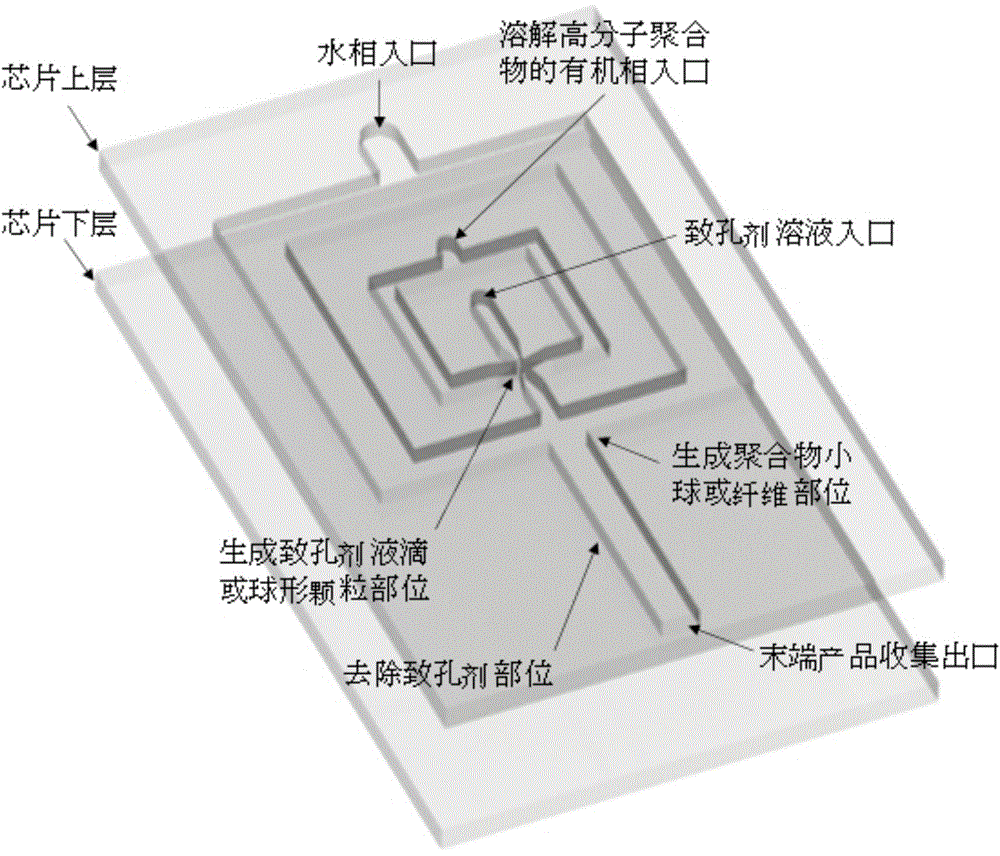

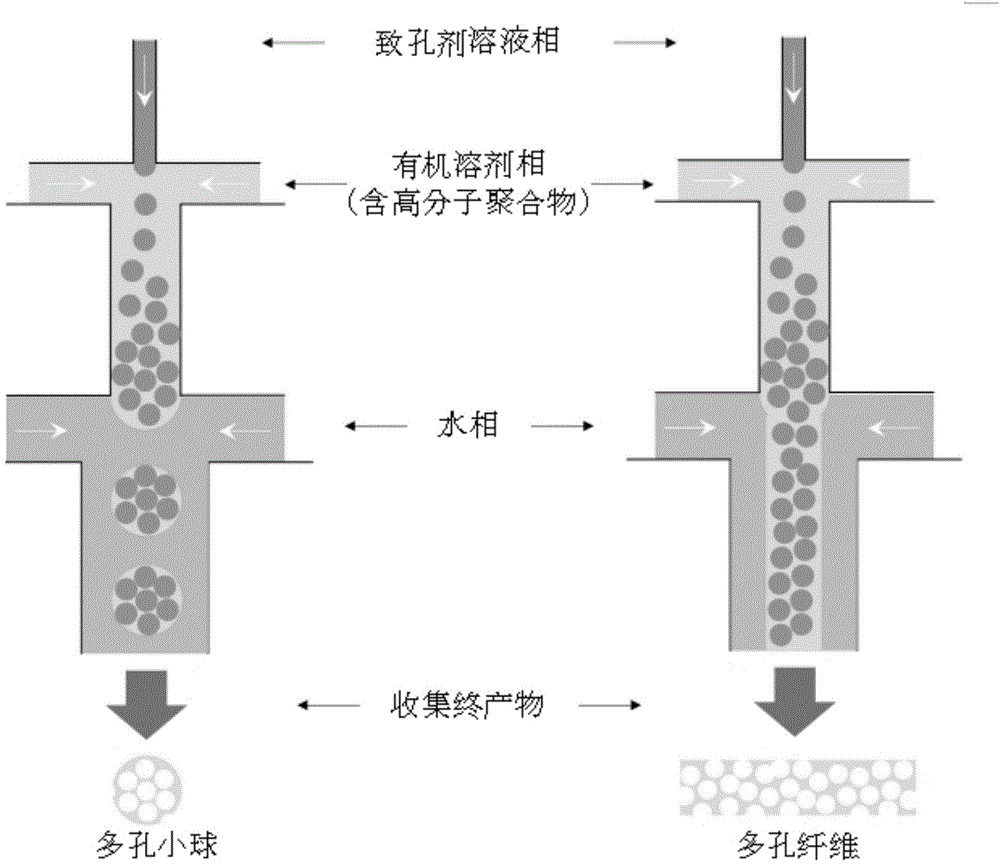

[0015] Preparation of poly(lactic-co-glycolic acid) (PLGA) porous pellets by using liquid droplets as porogen

[0016] Prepare 2w / w% PVA aqueous solution, 1.5w / w% PLGA dichloromethane solution, and add 2w / w% surfactant Span80 in PLGA solution. The pure water is introduced into the chip from the porogen inlet, the PLGA solution is introduced into the chip from the organic phase inlet, and the PVA solution is introduced into the chip from the water phase inlet. Observe under the microscope and adjust the flow rate of each phase, so that the pure water produces droplets under the action of the PLGA solution, and the PLGA solution produces droplets under the action of the PVA solution. The PLGA solution droplets are much larger than the pure water droplets, so a large amount of Pure water droplets are wrapped in PLGA solution. In the microfluidic channel, dichloromethane is volatilized into the PVA solution, and PLGA is precipitated and solidified to form PLGA beads. Due to the o...

Embodiment 2

[0018] Preparation of Polylactic Acid (PLA) Porous Fibers Using Microspheres as Porogen

[0019] Prepare 7.5w / w% gelatin in water, 10w / w% PLA in dichloromethane, 1:1 w / w glycerin and water mixture. The gelatin aqueous solution is introduced into the chip from the porogen inlet, the PLA solution is introduced into the chip from the organic phase inlet, and the glycerin aqueous solution is introduced into the chip from the water phase inlet. Observe under the microscope and adjust the flow rate of each phase, so that the gelatin aqueous solution produces droplets under the action of the PLGA solution, and apply low-temperature stimulation to the part containing the gelatin aqueous solution droplets on the chip, so that the gelatin aqueous solution solidifies into gelatin solid particles; Under the action of glycerin aqueous solution, a laminar flow is formed, and dichloromethane volatilizes in the channel, causing PLA to precipitate and form PLA fibers. Since the PLA solution co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com