Environment-friendly recovered grease decolorizing agent and preparation method thereof

An environmentally friendly, decolorizing agent technology, applied in the field of decolorizing agents, can solve problems such as consumer health hazards, achieve good decolorizing effect, high decolorizing rate, and reduce the effect of peroxide value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

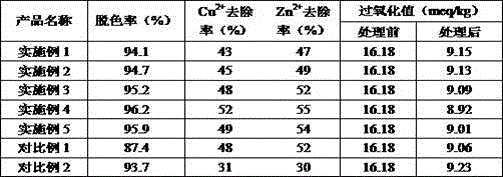

Examples

Embodiment 1

[0017] An environment-friendly recycled oil decolorizer, prepared from the following ingredients in parts by weight: 10 parts of washed and acidified rice husk ash, 10 parts of unwashed and acidified rice husk ash, 10 parts of carbonized bean husk ash, 1 part of chitosan, 10 parts of 0.1 part of dialkyl dimethyl benzyl ammonium chloride, 0.1 part of epicatechin gallate, 0.1 part of dilauryl thiodipropionate, 0.1 part of sorbic acid, 0.1 part of butyl p-hydroxybenzoate, ethanol 2 parts, 1 part hydrochloric acid, 5 parts water.

[0018] The preparation method of the above-mentioned environment-friendly reclaimed grease decolorizer is as follows: first mix chitosan, hydrochloric acid and water, and use a magnetic stirrer to stir for 10 minutes at a rotating speed of 100 rpm and a temperature of 30° C. to obtain solution A; mix sorbic acid, butyl p-hydroxybenzoate The ester and ethanol were mixed and stirred for 10 minutes to obtain solution B, then the remaining components, solut...

Embodiment 2

[0020] An environment-friendly recycled oil decolorizer, prepared from the following ingredients in parts by weight: 11 parts of washed and acidified rice husk ash, 11 parts of unwashed and acidified rice husk ash, 13 parts of carbonized bean husk ash, 1.3 parts of chitosan, ten 0.12 parts of dialkyl dimethyl benzyl ammonium chloride, 0.13 parts of epicatechin gallate, 0.13 parts of dilauryl thiodipropionate, 0.13 parts of sorbic acid, 0.12 parts of butyl p-hydroxybenzoate, ethanol 3 parts, 1.2 parts of hydrochloric acid, 6 parts of water.

[0021] The preparation method of the above-mentioned environment-friendly reclaimed grease decolorizer is as follows: first mix chitosan, hydrochloric acid and water, and use a magnetic stirrer to stir for 13 minutes at a rotating speed of 110 rpm and a temperature of 33° C. to obtain solution A; mix sorbic acid, butyl p-hydroxybenzoate The ester and ethanol were mixed and stirred for 13 minutes to obtain solution B, then the remaining com...

Embodiment 3

[0023] An environment-friendly recycled oil decolorizer, prepared from the following ingredients in parts by weight: 12.5 parts of washed and acidified rice husk ash, 12.5 parts of unwashed and acidified rice husk ash, 15 parts of carbonized bean husk ash, 1.5 parts of chitosan, ten 0.15 parts of dialkyl dimethyl benzyl ammonium chloride, 0.15 parts of epicatechin gallate, 0.15 parts of dilauryl thiodipropionate, 0.15 parts of sorbic acid, 0.15 parts of butyl p-hydroxybenzoate, ethanol 3.5 parts, 1.5 parts hydrochloric acid, 7.5 parts water.

[0024] The preparation method of the above-mentioned environment-friendly reclaimed grease decolorizer is as follows: first mix chitosan, hydrochloric acid and water, and use a magnetic stirrer to stir for 15 minutes at a rotating speed of 125 rpm and a temperature of 35° C. to obtain solution A; mix sorbic acid, butyl p-hydroxybenzoate The ester and ethanol were mixed and stirred for 15 minutes to obtain solution B, then the remaining c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com