Recycling and reusing method of waste vanadium tungsten titanium-based denitration catalyst

A denitrification catalyst, vanadium tungsten titanium technology, applied in the field of flue gas purification, can solve problems such as the inability to directly apply catalyst production, and achieve the effects of easy centralized and rapid processing, resource recycling, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

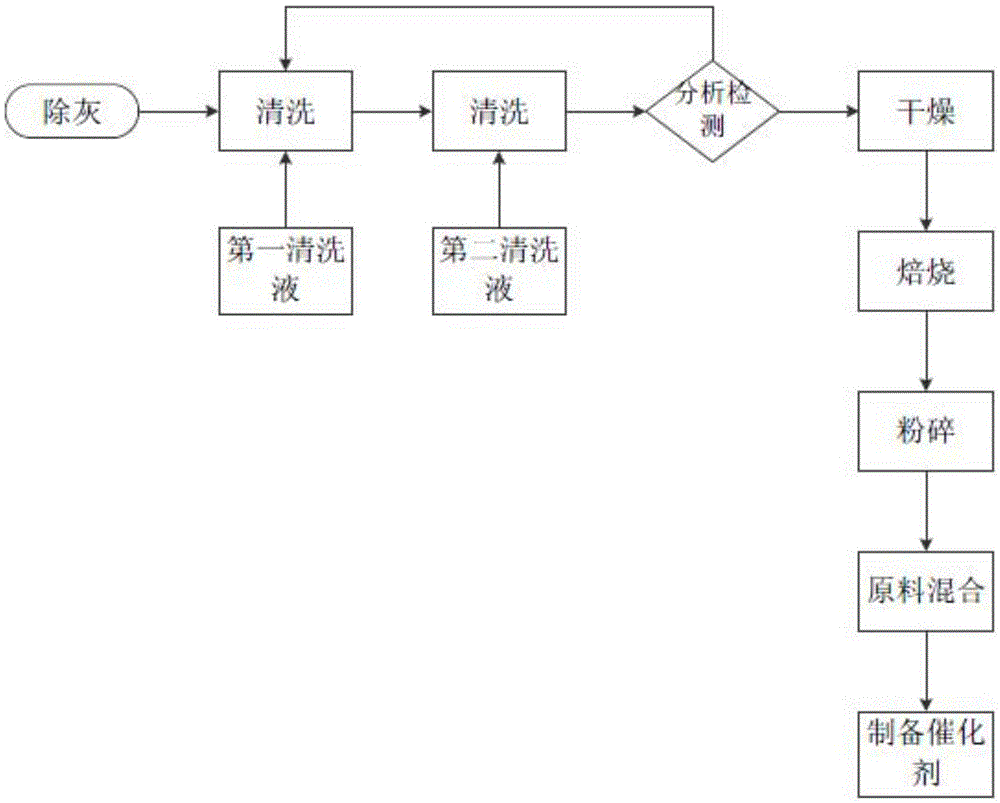

[0043] A method for recycling a waste vanadium-tungsten-titanium-based denitration catalyst, the specific steps of which are as follows:

[0044] (1), take 0.001m 3 150mm×150mm×1100mm deactivated honeycomb catalyst V with operation over 24000h 2 o 5 -WO 3 / TiO 2 The catalyst is deashed by negative pressure vacuum equipment to completely remove the dust on the surface of the catalyst and in the pores.

[0045] (2), prepare the first cleaning solution and the second cleaning solution: the formula of the first cleaning solution is: 1% sodium hydroxide, 0.5% sodium carbonate, 0.05% sodium edetate, 0.05% di Sodium ethylene triamine pentaacetate, 0.03% sodium citrate, 1% JFC, 0.01% OP-10, 0.01% Pyrexa, 0.05% sodium pyrophosphate and the balance deionized water; and The formula of the second cleaning solution is: 3% sulfuric acid, 0.5% citric acid, 0.1% tartaric acid, 0.01% ethylenediaminetetraacetic acid, 0.01% JFC, 0.005% OP-10, 1% Pingping The remaining amount of deionized w...

Embodiment 2

[0053] A method for recovering and reusing waste vanadium-tungsten-titanium-based denitration catalyst, the specific steps are as follows:

[0054] (1), take 0.001m 3 150mm×150mm×1100mm deactivated honeycomb catalyst V with operation over 24000h 2 o 5 -WO 3 / TiO 2 The catalyst is deashed by negative pressure vacuum equipment to completely remove the dust on the surface of the catalyst and in the pores.

[0055] (2), prepare the first cleaning solution and the second cleaning solution: the formula of the first cleaning solution is: 1% sodium hydroxide, 1% potassium hydroxide, 1% sodium carbonate, 0.05% ethylenediaminetetra Sodium acetate, 0.1% sodium diethylenetriaminepentaacetate, 0.05% sodium nitrilotriacetate, 0.1% sodium citrate, 0.1% JFC, 1% OP-10, 0.1% pepina, 0.1% sodium pyrophosphate and the deionized water of the balance; and the second cleaning liquid formula is: 1% sulfuric acid, 1% citric acid, 1% oxalic acid, 0.5% tartaric acid, 0.02% ethylenediaminetetra Ace...

Embodiment 3

[0063] A method for recovering and reusing waste vanadium-tungsten-titanium-based denitration catalyst, the specific steps are as follows:

[0064] (1), take 0.003m 3 150mm×150mm×1100mm deactivated honeycomb catalyst V with operation over 24000h 2 o 5 -WO 3 / TiO 2 The catalyst is deashed by negative pressure vacuum equipment to completely remove the dust on the surface of the catalyst and in the pores.

[0065](2), prepare the first cleaning solution and the second cleaning solution: the formula of the first cleaning solution is: 1% sodium hydroxide, 1% potassium hydroxide, 1% sodium carbonate, 0.05% ethylenediaminetetra Sodium acetate, 0.1% sodium diethylenetriaminepentaacetate, 0.05% sodium nitrilotriacetate, 0.1% sodium citrate, 0.1% JFC, 0.1% OP-10, 1% pepina, 0.1% sodium pyrophosphate and the remaining amount of deionized water; the second cleaning liquid formula is: 5% sulfuric acid, 1% citric acid, 0.02% ethylenediaminetetraacetic acid, 0.1% nitrilotriacetic acid, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com