A skin with a surface helium barrier layer and its preparation method

A technology of barrier layer and skin, applied in the field of skin materials, can solve the problems of inability to realize commercial application, high cost of multi-layer lamination, difficult to apply on a large scale, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

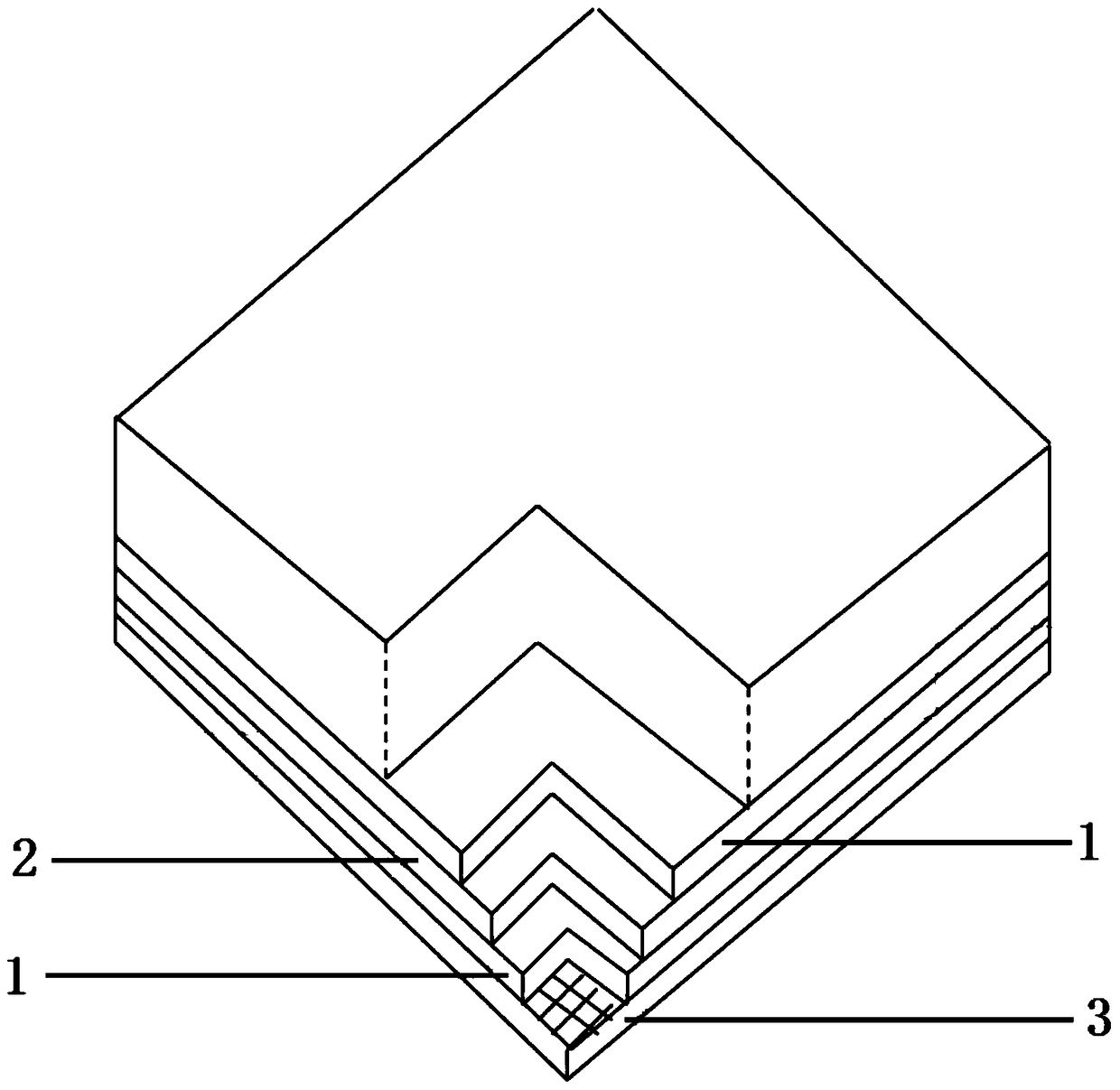

[0037] A skin with a surface helium barrier, structured as figure 1 , the surface of the skin 3 is alternately laminated with PDDA layers 1 and graphene powder layers 2, a total of 20 layers.

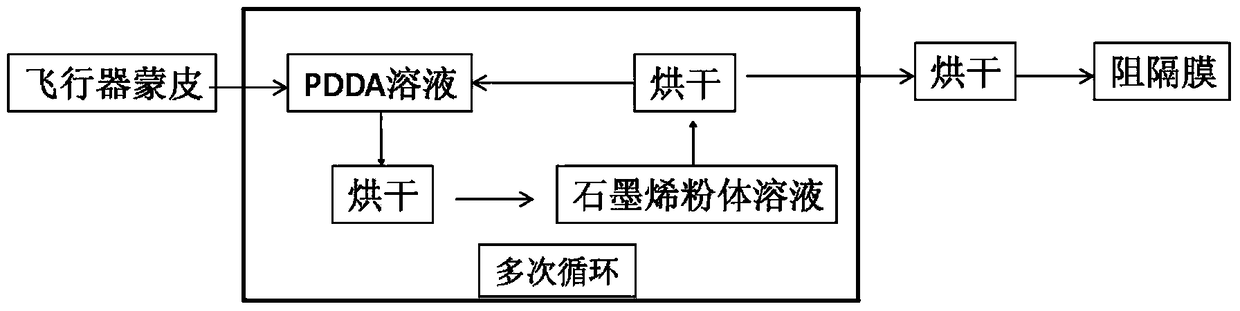

[0038] see figure 2 The process flow of the method is to attach the PDDA layer and the graphene powder layer to the surface of the skin by the method of mutual sticking, and the preparation method is as follows:

[0039] Attachment of PDDA layer: Attach a layer of PDDA solution on the cleaned skin by dipping and pulling. The mass fraction of PDDA solution is 0.5%. The hides are dried at 100°C to remove moisture. Among them, the skin is cleaned by ultrasonication of deionized water added with surfactant for ≥1min, then rinsed with deionized water (or ultrapure water or distilled water) for ≥3 times, and dried at 60°C to 200°C;

[0040] In addition to soaking and pulling, PDDA can be attached to the skin surface by smooth roller coating, screen roller coating, doctor blade coating, sp...

Embodiment 2

[0046] A skin with a surface helium barrier, structured as figure 1 , the surface of the skin 3 is alternately laminated with PDDA layers 1 and graphene powder layers 2, a total of 30 layers.

[0047] The preparation method is basically the same as in Example 1, except that:

[0048] 1. During the attachment process of the PDDA layer, the mass fraction of PDDA solution is 0.01wt%, and the drying temperature is 200°C;

[0049] 2. During the attachment process of the graphene powder layer, the concentration of the graphene solution is 10wt%, and the drying temperature is 60°C.

[0050] 3. Repeat the operation process of attaching the PDDA layer and the graphene powder layer 15 times each.

Embodiment 3

[0052] A skin with a surface helium barrier, structured as figure 1 , the surface of the skin 3 is alternately laminated with PDDA layers 1 and graphene powder layers 2, a total of 100 layers.

[0053] The preparation method is basically the same as in Example 1, except that:

[0054] 1. During the attachment process of the PDDA layer, the mass fraction of the PDDA solution is 10wt%, and the drying temperature is 60°C;

[0055] 2. During the attachment process of the graphene powder layer, the concentration of the graphene solution is 0.01wt%, and the drying temperature is 60°C.

[0056] 3. Repeat the operation process of attaching the PDDA layer and the graphene powder layer 50 times each.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com