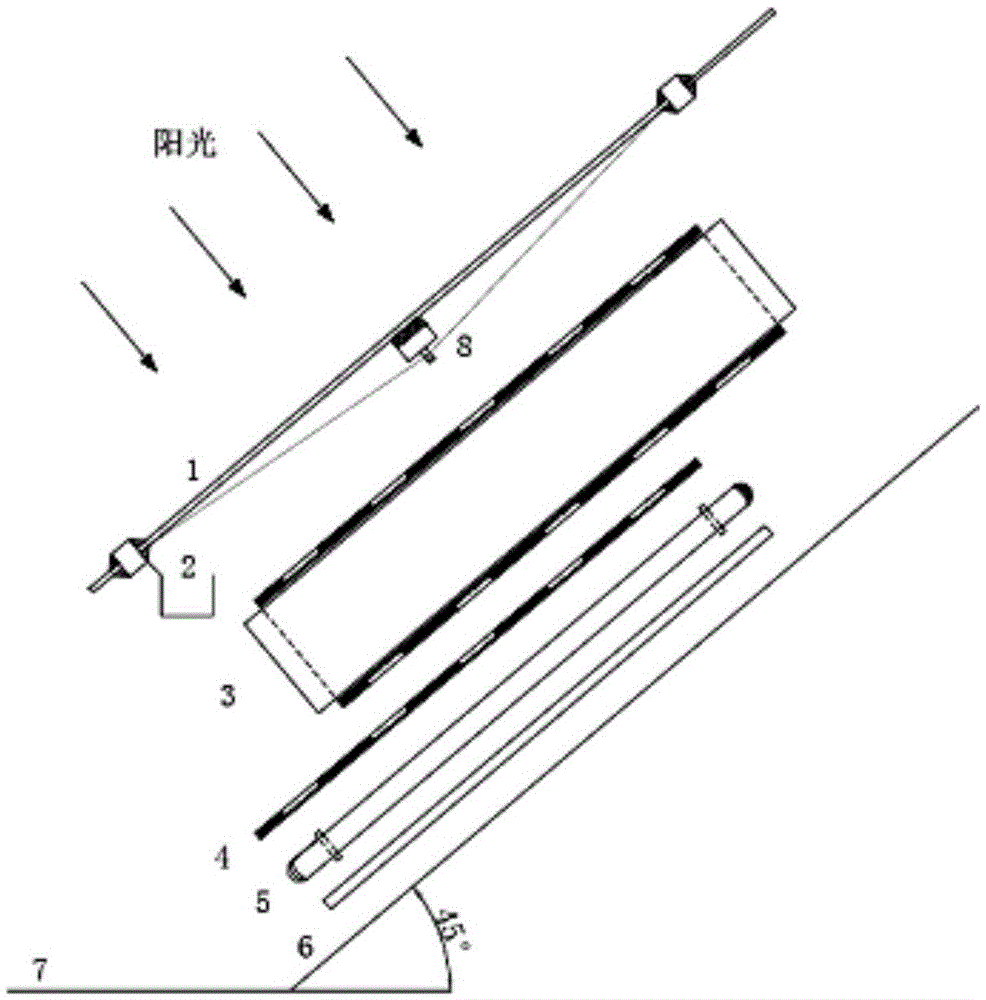

Argillaceous biomass refuse solar interlayer drying device and two-stage drying method

A technology of biomass and solar energy, applied in chemical instruments and methods, waste treatment, transportation and packaging, etc., can solve the problems of large floor area and low efficiency of solar energy utilization, save site area, reduce device volume, improve dryness The effect of melting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

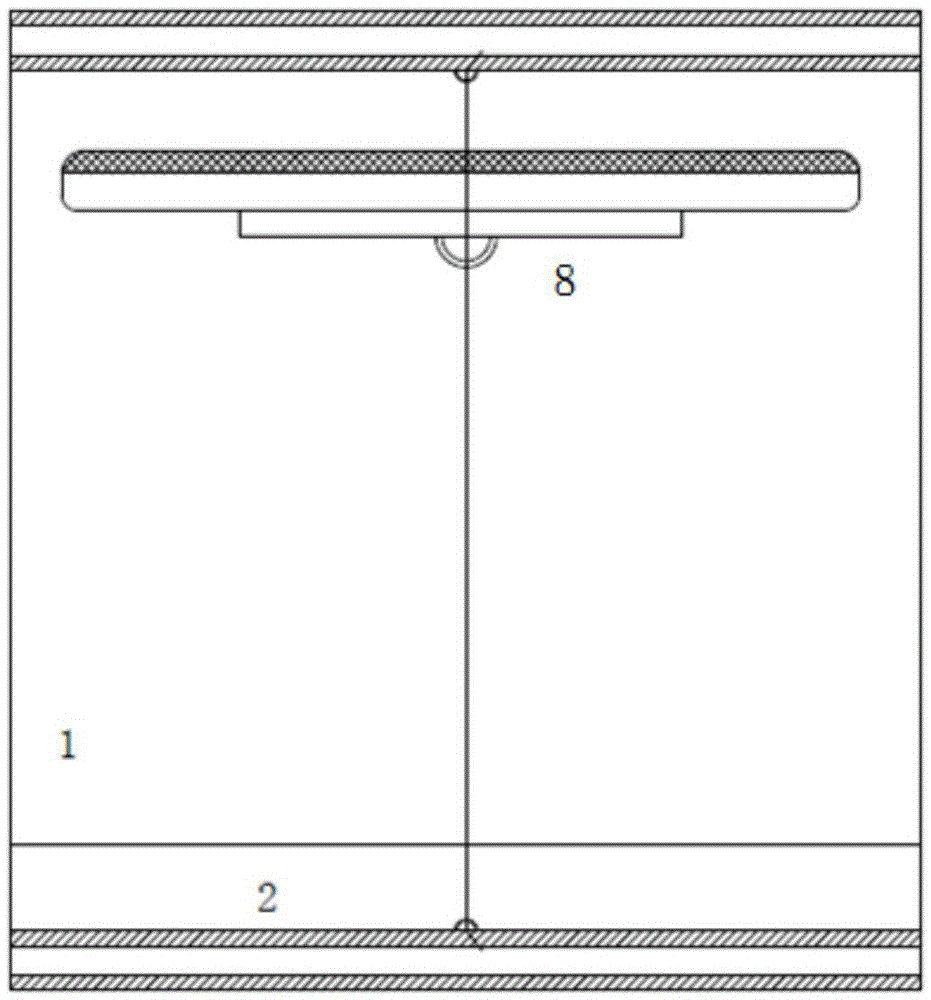

Method used

Image

Examples

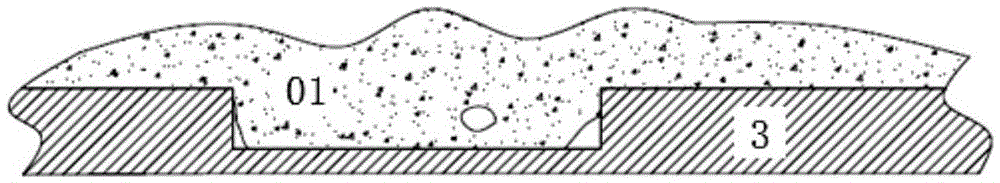

Embodiment 1

[0060] After dehydration, the moisture content of the sludge is 90%. Through the high-pressure pump or other mechanical distributing system, the sludge is evenly laid on the upper conveyor plate with a thickness of 0.5cm, and then enters the flexible conveyor belt 3. The temperature is 72-82°C during the day and at night. 15-40°C, after drying for 1.5 days, its moisture content will reach 40%; then transfer to the right end of the flexible conveyor belt 3, use gravity and scraper system to scrape off the sludge, enter the rigid conveyor belt 4, use the airtight interlayer The air source in the space and the reclaimed water source heat pump heating system 5 on the back are further dried, and the final moisture content reaches <20%; the dried sludge enters the collecting tank and the lower part by using the mechanical scraper and gravity. One-step utilization mode; the water vapor evaporated during the process is condensed on the light-transmitting layer 1, and the condensed wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com