Quick preparation method and application of chickpea polypeptide powder

A technology of chickpea polypeptide and chickpea, which is applied in the field of rapid preparation of chickpea polypeptide powder, can solve problems such as toxic and side effects, and achieve the effect of simple equipment and easy scale-up preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

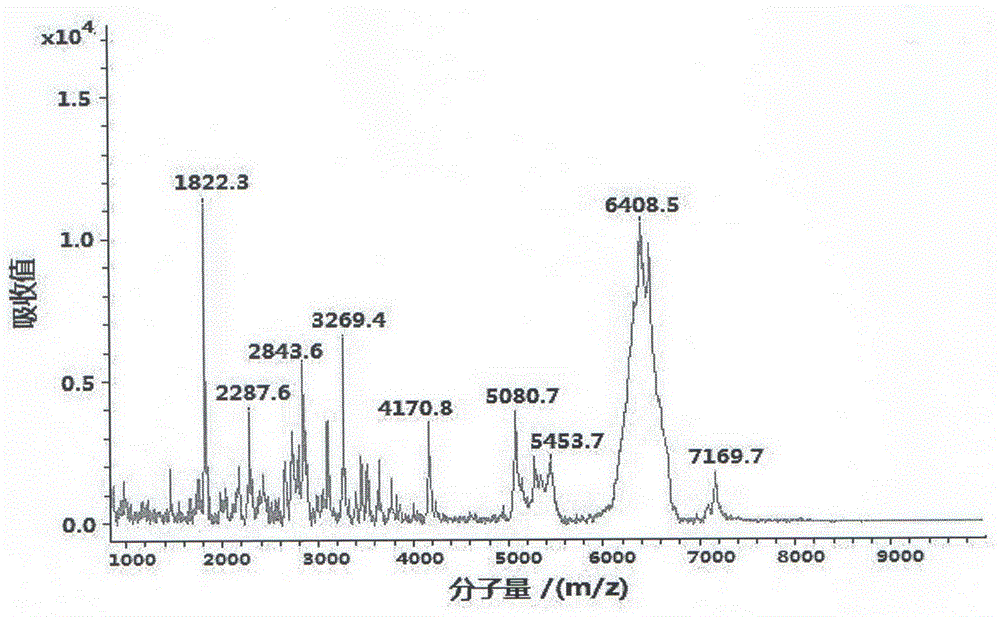

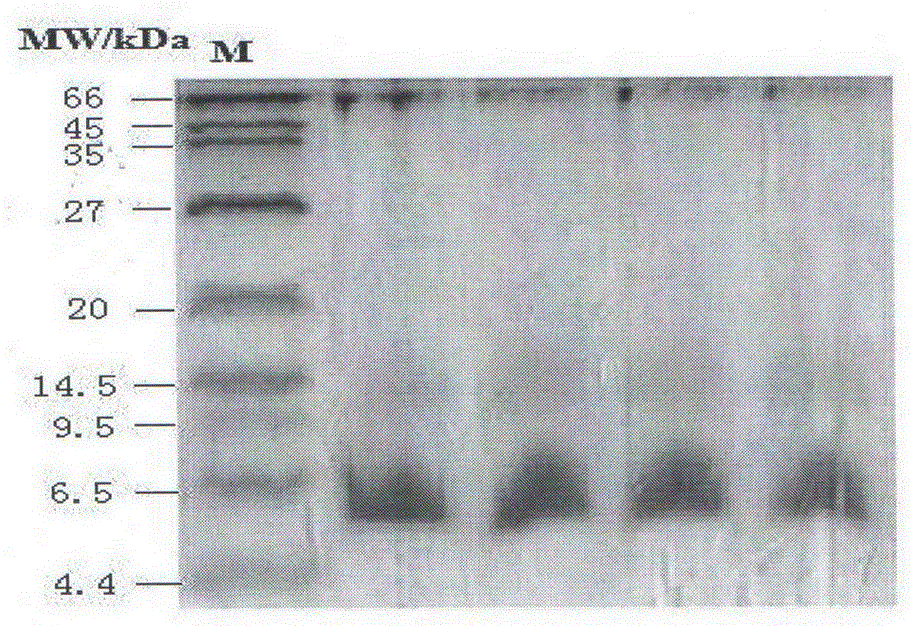

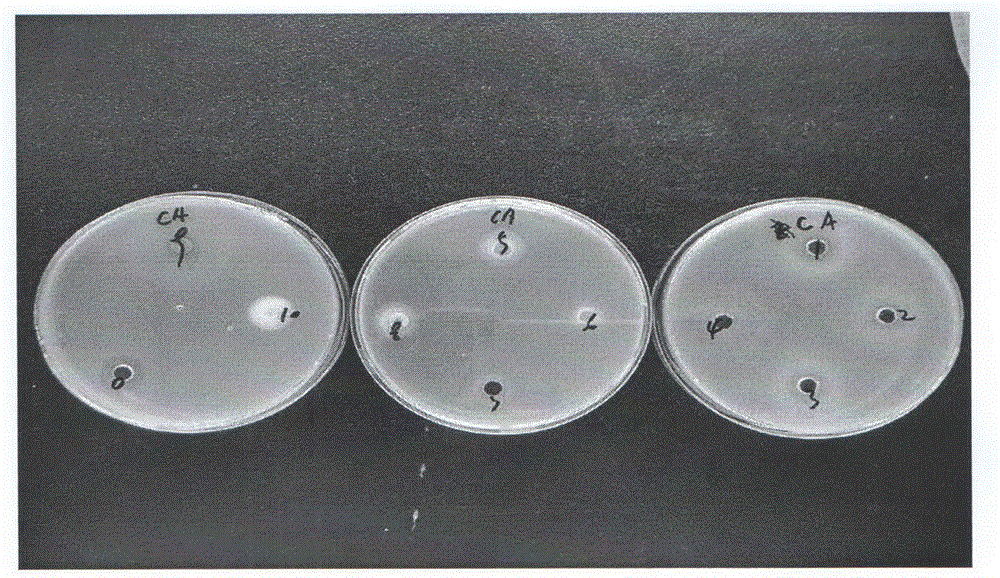

Method used

Image

Examples

Embodiment 1

[0045] a. Take 500.00g of chickpea watercress, rinse them with water for 3 times until they are completely clean, filter them with gauze respectively, combine the washed chickpea watercress, dry them at low temperature, and control the temperature at 40°C. Crushed by a pulverizer, the crushed particle size is 200 mesh, and petroleum ether is added according to the weight ratio of material to liquid at 1:5, stirred at room temperature for 1 hour, repeated extraction 3 times until no oil is extracted, suction filtered, combined and precipitated, and naturally Dry until no petroleum ether solvent remains, and obtain 382.19 g of defatted chickpea flour;

[0046] b, adding concentration to the defatted chickpea powder obtained in step a is 50% edible ethanol, the ratio of solid to liquid is 1:5, stirring and extracting at room temperature for 2 hours, extracting 3 times each time, and suction filtration under reduced pressure, Combine the extracts, separate the impurities, and obta...

Embodiment 2

[0051] a. Take 300.00g of chickpea watercress, wash them with water for 3 times until they are completely clean, filter them with gauze respectively, combine the washed chickpea watercress, dry them at low temperature, and control the temperature at 40°C. Crushed by a pulverizer, the crushed particle size is 200 mesh, and petroleum ether is added according to the weight ratio of material to liquid at 1:5, stirred at room temperature for 2 hours, extracted repeatedly for 3 times until no oil is extracted, filtered with suction, combined and precipitated, and naturally Dry until there is no petroleum ether solvent residue to obtain 190.00 g of defatted chickpea flour;

[0052] b. Add edible ethanol with a concentration of 50% to the fully defatted chickpea flour in step a, the ratio of solid to liquid is 1:5, stir and extract at room temperature for 3 hours, extract 3 times each time, filter under reduced pressure, and combine extracting liquid, separating impurities, obtaining ...

Embodiment 3

[0057] a. Take 500.00g of dry organic solvent to extract the chickpea dregs after the small molecular compound, pulverize through a pulverizer, the pulverization particle size is 200 mesh, add petroleum ether according to the weight ratio of material to liquid as 1:5, and stir at room temperature for 1 hour, Repeat the extraction 3 times until no oil is extracted, filter with suction, combine the precipitates, and dry naturally until no petroleum ether solvent remains to obtain 385.00 g of defatted chickpea flour;

[0058] b. Add edible ethanol with a concentration of 50% to the chickpea flour fully defatted in step a, the ratio of solid to liquid is 1:5, stir and extract at room temperature for 2 hours, extract 4 times each time, filter under reduced pressure, and combine extracting liquid, separating impurities, obtaining crude extracting liquid for subsequent use;

[0059] c. Purify the crude extract obtained in step b with a regenerated cellulose flat membrane with a molec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com