Heat-resistant and shock-resistant medical hard PVC material and preparation method thereof

A PVC material and impact-resistant technology, applied in the field of medical materials, can solve the problems of lack of medical rigid PVC materials, and achieve the effects of excellent processing fluidity, excessive shear force and simple process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

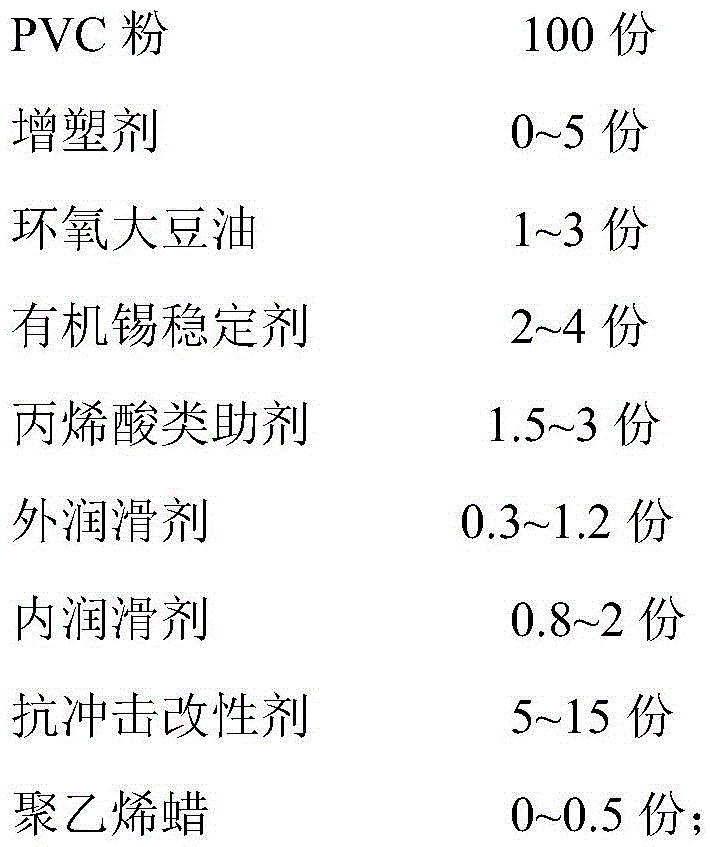

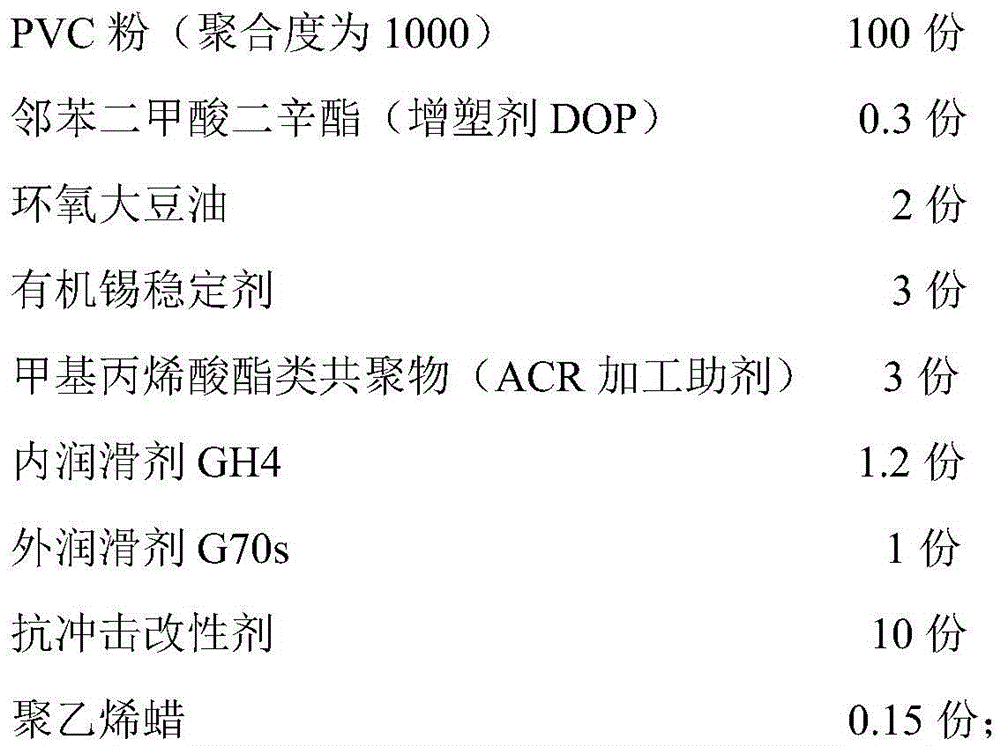

[0025] A heat-resistant and shock-resistant medical rigid PVC material, which comprises the following raw material components in parts by weight:

[0026]

[0027] Wherein the impact modifier is a mixture of butadiene acrylonitrile copolymer (nitrile rubber) and methyl methacrylate-butadiene-styrene copolymer (MBS).

[0028] The preparation process of the medical rigid PVC material:

[0029] (1) High mixing: Add PVC powder with a degree of polymerization of 1000, dioctyl phthalate, epoxy soybean oil, and organic tin stabilizer into the high mixing tank according to the ratio of raw material components, stir at low speed, heat, add methyl Acrylate copolymer, stir at high speed at 60°C, add internal lubricant GH4 when the temperature rises to 85°C, add external lubricant G70s, polyethylene wax and impact modifier when the temperature continues to rise to 90°C, and continue to heat up to High mixing is completed at 110°C;

[0030] (2) Low mixing: discharge the mixture obtain...

Embodiment 2

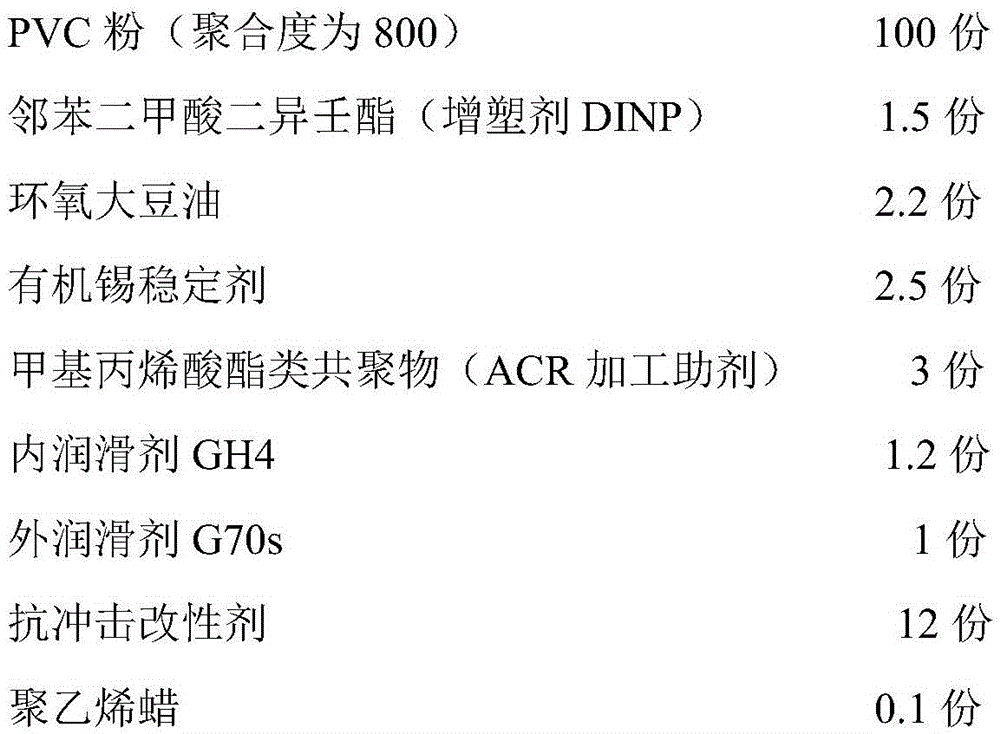

[0033] A heat-resistant and shock-resistant medical rigid PVC material, which comprises the following raw material components in parts by weight:

[0034]

[0035] Wherein the impact modifier is butadiene acrylonitrile copolymer (nitrile rubber).

[0036] The preparation process of the medical rigid PVC material is the same as that of the above-mentioned embodiment 1.

Embodiment 3

[0038] A heat-resistant and shock-resistant medical rigid PVC material, which comprises the following raw material components in parts by weight:

[0039]

[0040] Wherein the impact modifier is butadiene acrylonitrile copolymer (nitrile rubber).

[0041] The preparation process of the medical rigid PVC material is the same as that of the above-mentioned embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com