A kind of preparation method of high softening point asphalt composition granule

A technology of asphalt and composition with high softening point, applied in the direction of drilling composition, chemical instruments and methods, building structures, etc., can solve the problem of the reduction of effective components of asphalt particles, difficulty in plugging and filter reduction, and particle deformation Limited capacity and other issues, to achieve the effect of reducing energy consumption, increasing performance, and increasing deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

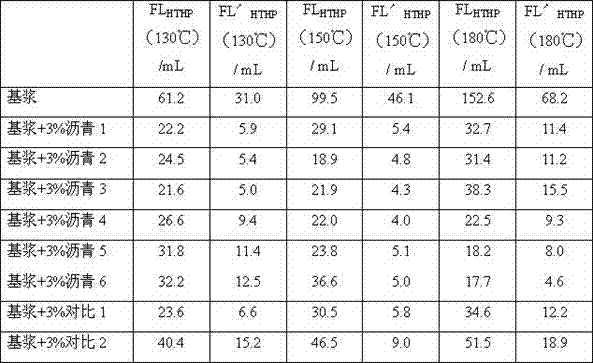

Examples

Embodiment 1

[0032] Take 100g of oxidized pitch (softening point: 146.5°C) and 120g of kerosene in a container, stir at room temperature (25°C) for 20 minutes, and prepare the mother liquor after being fully mixed. Take 75g of 100-mesh styrene-butadiene rubber powder, put the prepared asphalt mother liquor in a watering can, spray evenly on the rubber powder particles, and stir while spraying. After spraying, send it into the reactor and feed compressed air, adjust the pressure reducing valve so that the gas inlet pressure of the reactor is 0.20MPa, keep the temperature of the reactor at 185°C, stir for 60 minutes, then raise the temperature to 210°C, and stir for 25 minutes , then add 6.2g cetyltrimethylammonium chloride and put it in a freezer to freeze (freezing temperature -35°C, freezing time is 12 hours), take it out and put it into a vibrating sieve (80-mesh standard sieve is used for the bottom of the sieve) After vibrating and pulverizing for 20 seconds, high softening point aspha...

Embodiment 2

[0034] Take 100g of deasphalt (softening point: 157.2°C) and 160g of diesel oil in a container, stir at 40°C for 15 minutes, and mix thoroughly to obtain the mother liquor. Take 46g of 120-mesh butyl rubber powder, put the prepared asphalt mother liquor in a watering can, spray evenly on the rubber powder particles, and stir while spraying. After spraying, send it into the reactor and feed compressed air, adjust the pressure reducing valve so that the gas inlet pressure of the reactor is 0.25MPa, keep the temperature of the reactor at 200°C, stir for 80 minutes, then raise the temperature to 260°C, and stir for 40 minutes , and then add 7.5g sodium lignosulfonate and place it in a freezer for freezing (freezing temperature -25°C, freezing time is 14 hours). After taking it out, put it into a vibrating sieve (100-mesh standard sieve is used as the bottom of the sieve) and vibrate and pulverize for 30 seconds, and the asphalt composition particles with high softening point can b...

Embodiment 3

[0036]Take 100g of natural asphalt (softening point: 138.8°C) and 120g of kerosene in a container, stir at 30°C for 20 minutes, and prepare the mother liquor after fully mixing. Take 52g of 100-mesh neoprene rubber powder, put the prepared asphalt mother liquor in a watering can, spray evenly on the rubber powder particles, and stir while spraying. After the spraying is finished, send it into the reactor and feed compressed nitrogen gas, adjust the pressure reducing valve so that the gas inlet pressure of the reactor is 0.18MPa, keep the temperature of the reactor at 180°C, stir for 70 minutes, then raise the temperature to 230°C, and stir for 25 minutes , then add 9.0g of secondary alcohol sodium sulfate and place it in a freezer for freezing (freezing temperature -30°C, freezing time is 10 hours), take it out and put it into a vibrating sieve (80-mesh standard sieve is used at the bottom of the sieve) to vibrate and pulverize for 30s, and sieve The high softening point aspha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com