Preparation method of nanoscale core-shell structure super thermite

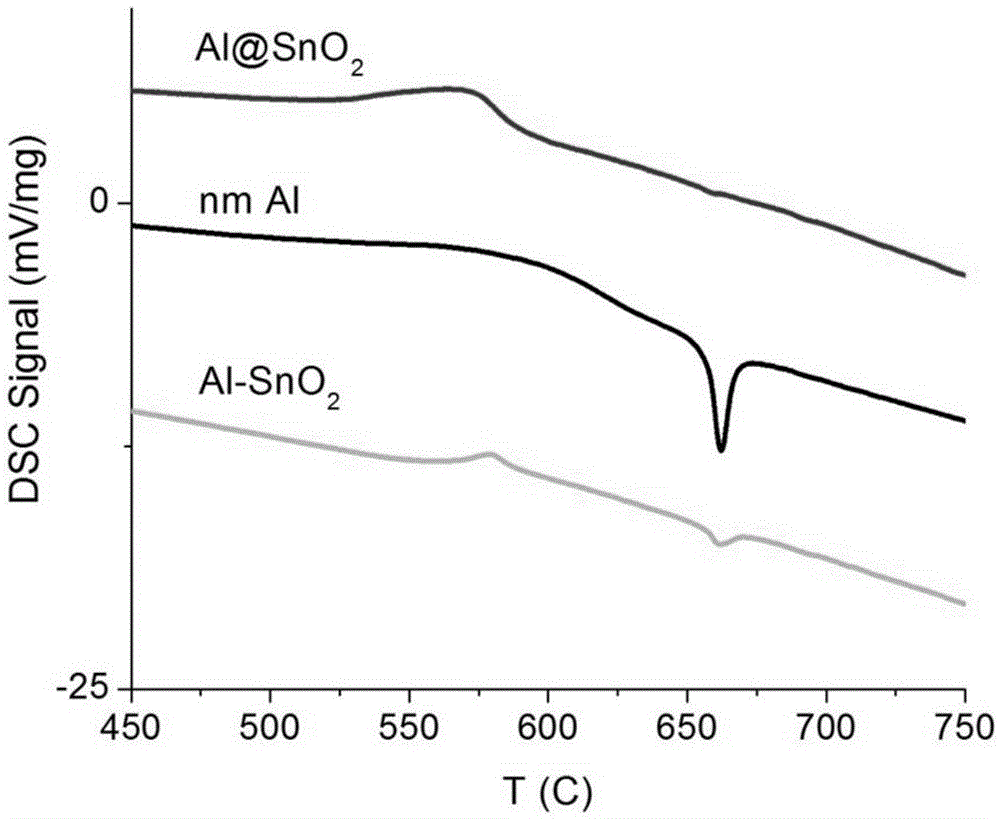

A technology of super thermite and core-shell structure, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of difficult to achieve precise adjustment of the thickness of the metal oxide cladding layer, cladding layer Integrity, poor uniformity and compactness, lack of precise control of the experimental process, etc., to achieve the effect of easy implementation and promotion, high degree of automation, and promotion of full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

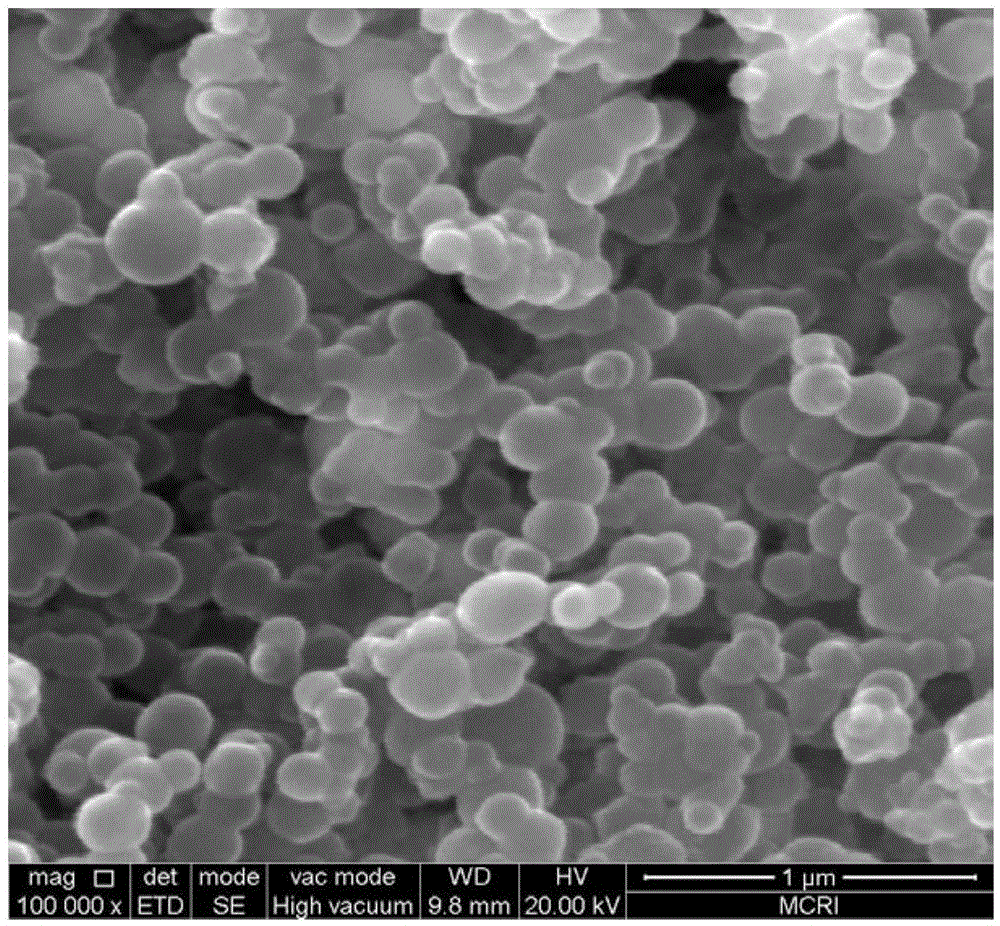

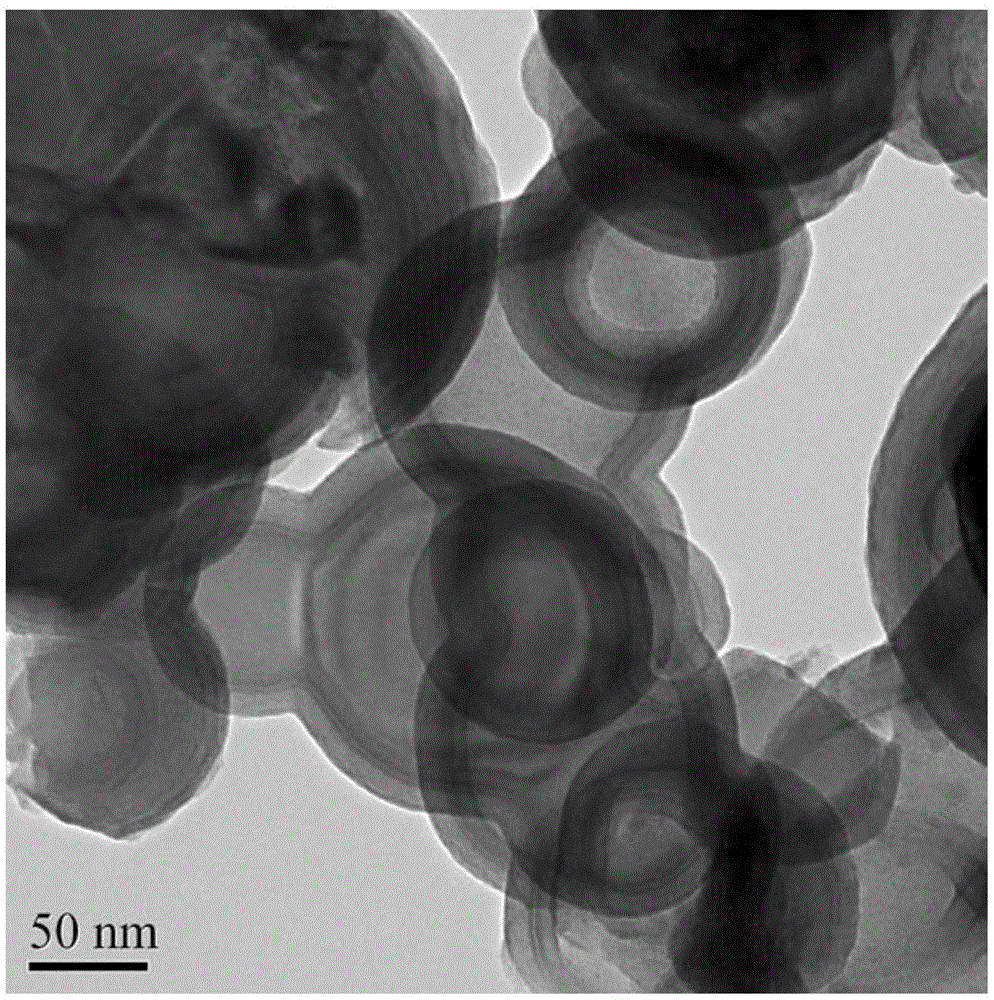

[0033] This example provides a method for preparing a nanoscale core-shell structure super thermite, which specifically includes the following steps:

[0034] Step 1: Place the nano-aluminum powder particles in the reaction chamber of the vapor phase atomic layer deposition system, seal the reaction chamber, feed nitrogen gas into the vapor phase atomic layer deposition system and vacuumize it, adjust the flow rate of nitrogen gas to 100 sccm, and adjust the outlet valve of the reaction chamber to make the chamber The internal pressure is controlled at 250Pa; and the sample temperature is kept at 300°C by heating;

[0035] Step 2: Perform atomic layer deposition on the nano-aluminum powder particles to form a coating film. A cycle of atomic layer deposition growth includes the following four links:

[0036] (1) Inject the first reaction precursor tin tetrachloride (SnCl 4 ) to make a saturated surface chemical reaction with the aluminum powder and replace the surface function...

Embodiment 2

[0049] This example provides a method for preparing a nanoscale core-shell structure super thermite, which specifically includes the following steps:

[0050] Step 1: Place the nano-aluminum powder particles in the reaction chamber of the vapor phase atomic layer deposition system, seal the reaction chamber, feed nitrogen gas into the vapor phase atomic layer deposition system and vacuumize, adjust the flow rate of nitrogen gas to 120 sccm, and adjust the outlet valve of the reaction chamber to make the chamber The internal pressure is controlled at 133Pa; and the sample temperature is kept at 350°C by heating;

[0051] Step 2: Perform atomic layer deposition on the nano-aluminum powder particles to form a coating film. A cycle of atomic layer deposition growth includes the following four links:

[0052] (1) Inject the first reaction precursor ferrocene (FeCp) into the reaction chamber 2 ) to make a saturated surface chemical reaction with the aluminum powder and replace the ...

Embodiment 3

[0065] This example provides a method for preparing a nanoscale core-shell structure super thermite, which specifically includes the following steps:

[0066] Step 1: Place the nano-aluminum powder particles in the reaction chamber of the vapor-phase atomic layer deposition system, seal the reaction chamber, feed helium into the vapor-phase atomic layer deposition system and vacuumize it, adjust the helium flow rate to 120 sccm, and adjust the outlet valve of the reaction chamber Control the pressure in the chamber at 133Pa; and make the sample temperature at 150°C by heating;

[0067] Step 2: Perform atomic layer deposition on the nano-aluminum powder particles to form a coating film. A cycle of atomic layer deposition growth includes the following four links:

[0068] (1) Inject the first reaction precursor titanium tetraisopropoxide (Ti(OPr)) into the reaction chamber 4 ) to make a saturated surface chemical reaction with the aluminum powder and replace the surface functio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com