Flow shear stress mediated collagen self-assembly method

A fluid shear force, self-assembly technology, applied in the field of biomedical materials and biomechanics, can solve the problems of not being able to reproduce the assembly process well, ignoring the mechanical microenvironment, etc., achieving easy recovery and processing, simple preparation method, The effect of good biocompatibility and degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

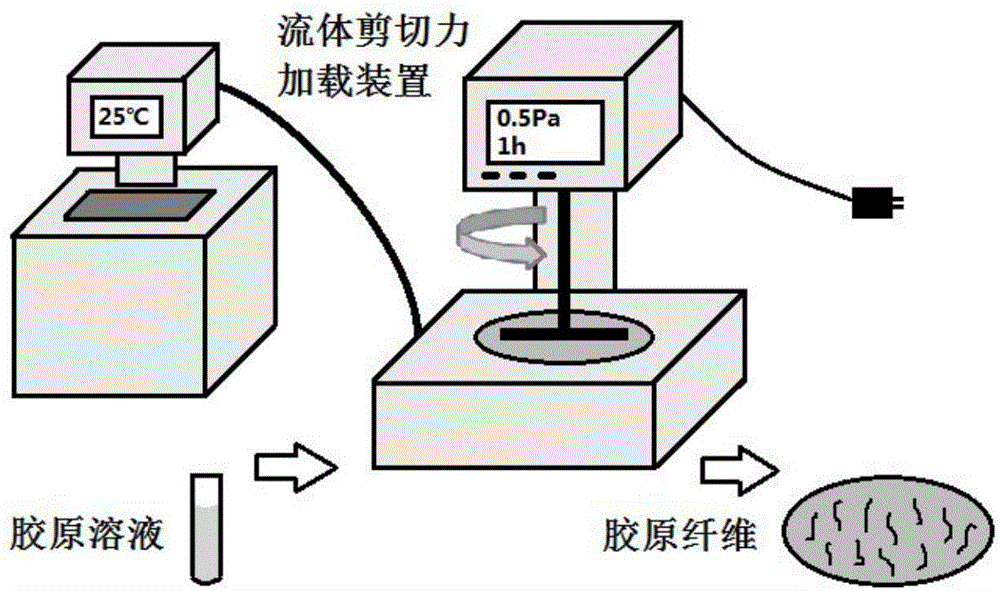

[0024] Example 1: Collagen self-assembly mediated by fluid shear force

[0025] Add 400 μL of 10xPBS solution, 2.76 μL of 1M NaOH solution, and 3.477 mL of deionized water to the centrifuge tube in sequence, mix well, and take out the type I rat tail collagen solution with a mass concentration of 3.34 mg / mL from the refrigerator at 4 °C. Take 119.8 μL and add it to prepare a sample solution with a mass concentration of 0.10 mg / mL, and adjust the pH between 7.0 and 7.4 with diluted ammonia water. Take 3.9mL of the sample solution and drop it on the plate of the cone-plate viscometer, put down the cone-plate, set the fluid shear force to 0.5Pa, the action time is 1h, the reaction temperature is 25°C, and the force is applied. After the stress loading was completed, the suspension was collected, centrifuged at high speed and washed 3 times. The precipitate was frozen in a -20°C refrigerator for 5 hours, and then transferred to a vacuum freeze dryer for 12 hours to freeze-dry to ...

Embodiment 2

[0026] Example 2: Collagen self-assembly mediated by fluid shear force

[0027] Add 400 μL of 10xPBS solution, 2.76 μL of KOH solution with a molar concentration of 1M, and 3.477 mL of deionized water in sequence in the centrifuge tube, mix well, and take out the type I rat tail collagen solution with a mass concentration of 3.34 mg / mL from the refrigerator at 4 °C. Take 119.8 μL and add it to prepare a sample solution with a mass concentration of 0.10 mg / mL, and adjust the pH between 7.0 and 7.4 with diluted sodium hydroxide solution. Take 3.9mL of the sample solution and drop it on the plate of the cone-plate viscometer, put down the cone-plate, set the fluid shear force to 0.5Pa, the action time is 1h, the reaction temperature is 25°C, and the force is applied. After the stress loading was completed, the suspension was collected, centrifuged at high speed and washed 3 times. The precipitate was frozen in a -20°C refrigerator for 5 hours, and then transferred to a vacuum fr...

Embodiment 3

[0028] Example 3: Collagen self-assembly mediated by fluid shear force

[0029] Add 400 μL of 10xPBS solution, 2.76 μL of 1M NaOH solution, and 3.477 mL of deionized water to the centrifuge tube in sequence, mix well, and take out the type I rat tail collagen solution with a mass concentration of 3.34 mg / mL from the refrigerator at 4 °C. Take 119.8 μL and add it to prepare a sample solution with a mass concentration of 0.10 mg / mL, and adjust the pH between 7.0 and 7.4 with diluted ammonia water. Take 3.9mL of the sample solution and drop it on the plate of the cone-plate viscometer, put down the cone-plate, set the fluid shear force to 2.0Pa, the action time is 1h, the reaction temperature is 25°C, and the force is applied. After the stress loading was completed, the suspension was collected, centrifuged at high speed and washed 3 times. The precipitate was frozen in a -20°C refrigerator for 5 hours, and then transferred to a vacuum freeze dryer for 12 hours to freeze-dry to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com