System for removing suspended particles from gas medium

A technology for suspended particles and gas media, which is applied in the field of purification and filtration, and can solve problems such as difficult cleaning, dirty surfaces, and limited use of purification devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

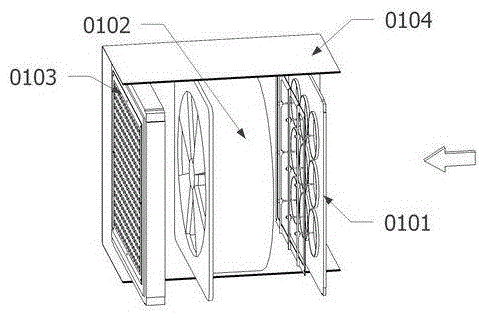

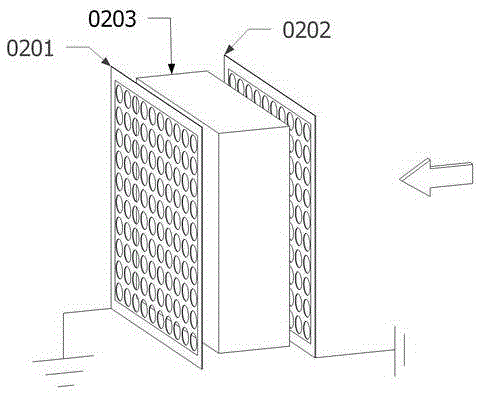

[0039] refer to figure 1 , the system of the present invention includes a charging component (0101), a forced ventilation component (0102), a filter component (0103), and a housing component (0104) that accommodates the above components and has the function of an airflow duct through which the gas can pass. The contaminated gas medium Driven by the forced ventilation component (0102), it first passes through the charging component (0101) in accordance with the direction of the arrow shown in the figure, in which the suspended particle pollutants are fully charged, and then pass through the filter component (0103). Under the action of the electric field, it is captured by the Coulomb force and left in the filter assembly (0103). The purified gas medium passes through filter components such as figure 2 The ground electrode (0201) shown, after its residual charge is neutralized, the treated gas exits the system.

[0040] In the arrangement of the system, the filter assembly (0...

no. 2 approach )

[0067] In the system of the present invention, the fiber material filled in the filter assembly (0103) can also be made of traditional polymer compound materials. Avoid the problem of secondary pollution to the environment caused by high-cost filter elements with low replacement frequency.

[0068] The benefits of such traditional polymer compound materials are that they are readily available in the market, are inexpensive, and can be recycled after proper cleaning.

no. 3 approach )

[0070] In addition, the fibrous material filled in the filter assembly (0103) is not limited to materials made of cellulose or fibrous materials, but also includes finished products made of fibrous materials with a variety of physical shapes that can allow gas to pass through. Paper products made of pulp, products processed from paper products, or other articles produced by using fibers in woven or non-woven forms, or a combination of two or more of the above materials.

[0071] One of the preferred implementation methods uses similar corrugated or honeycomb paperboards and is arranged in parallel with the direction of the electric field. Loose degradable plant fibers are arranged in the middle. In the case of low wind resistance, a large number of fibers polarized by the electric field will be captured by the charged suspended particles nearby. The beneficial effect is that different forms of fiber materials can be set for suspended particles of different particle sizes, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com