Method for advanced treatment of chemical waste water through SKL three-phase catalytic oxidation and BAF

A technology for catalytic oxidation and chemical wastewater, applied in the direction of aerobic process treatment, chemical instruments and methods, water/sewage treatment, etc. Effects of collision barrier, reduced operating cost, and convenient operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

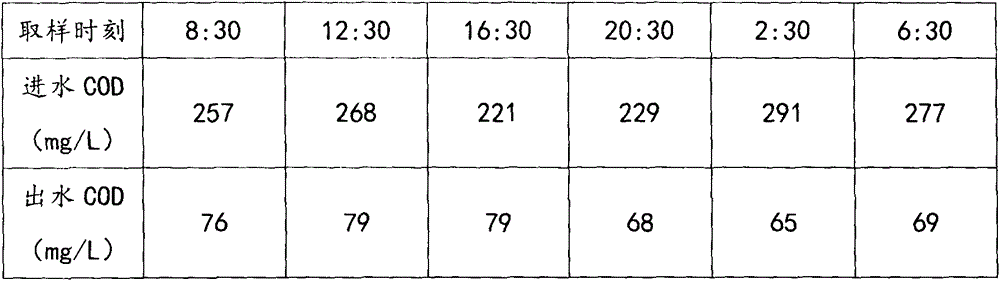

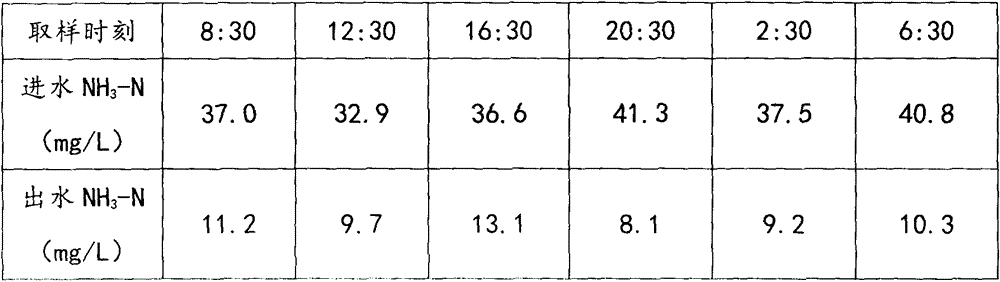

[0047] Wastewater source: the water from the biochemical secondary sedimentation tank of a sewage treatment plant in a chemical park. The sewage plant mainly treats the production wastewater from more than 70 chemical enterprises in the park, with a processing scale of 25,000 tons per day. After biochemical treatment, the COD of the effluent from the secondary sedimentation tank is 200-300mg / L, the chroma is high, the wastewater quality is complex and the water volume fluctuates greatly, the B / C is low, and it is biodegradable.

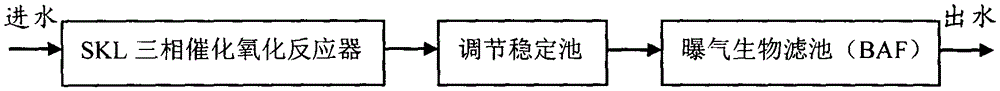

[0048] The wastewater was treated by SKL three-phase catalytic oxidation combined with one-stage BAF.

[0049] The effluent from the secondary sedimentation tank is lifted by the pump into the SKL three-phase catalytic oxidation reactor. First, it passes through the SKL-reactor type I, and the reaction time is 15 minutes. Amount of 400-500ppm, catalytic oxidation reaction, SKL-reactor type II reaction time 11min.

[0050] The effluent water from the ...

Embodiment 2

[0059] Wastewater source: MBR effluent after secondary treatment in a sewage treatment plant in a fine chemical industry park, the effluent COD is between 132-168mg / L, NH 3 -N is between 10.9-15.2mg / L.

[0060] The wastewater was treated by SKL three-phase catalytic oxidation combined with one-stage BAF.

[0061] The MBR effluent is lifted by the pump into the SKL three-phase catalytic oxidation reactor, firstly through the SKL-reactor type I, the reaction time is 10min, and the oxidant hydrogen peroxide is added before entering the SKL-reactor type II, the concentration is 30%, and the dosage is 300 -400ppm, for catalytic oxidation reaction.

[0062] The effluent water from the SKL three-phase catalytic oxidation reactor flows into the regulating and stabilizing pool by itself, and the water volume is further adjusted to perfect the reaction. The residence time is 45 minutes.

[0063] The effluent from the adjustment stabilization pond is pumped up into the biological aerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com