Preparation method of aerogel expanded perlite

A technology of expanded perlite and airgel, which is applied in the field of preparation of airgel expanded perlite, can solve problems such as high cost and lower thermal conductivity of perlite, and achieve improved adhesion, production efficiency and product quality, and improved Hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

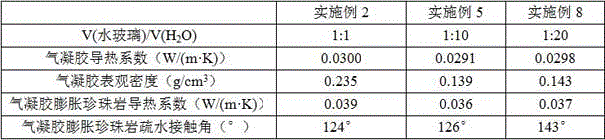

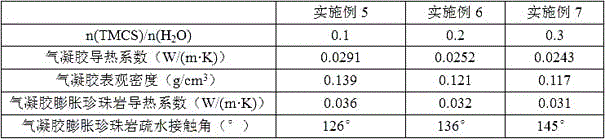

[0027] A method for preparing airgel expanded perlite, using water glass as a precursor, expanded perlite as a carrier, using a sol-gel method and a vacuum pressure impregnation full-cell method, and filling the airgel or The airgel expanded perlite is coated with expanded perlite, and the prepared airgel expanded perlite has a particle size greater than 0.05mm and a thermal conductivity of 0.020-0.065W / (m·K).

[0028] During specific implementation, the airgel is a hydrophobically modified airgel with a pore size of 2-50nm and a thermal conductivity of less than 0.03W / (m K); the expanded perlite is an expanded perlite with open pores. The diameter is greater than 0.05mm, and the thermal conductivity is 0.025-0.08W / (m K); the vacuum drying process is constant temperature drying or gradient temperature drying; the vacuum pressure impregnation full-cell method and vacuum drying process adopt the following equipment Integrated vacuum drying and pressure impregnation equipment.

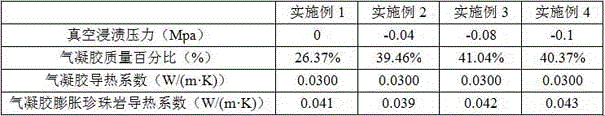

Embodiment 1

[0030] A preparation method of airgel expanded perlite, specifically comprising the steps of:

[0031] 1) Mix water glass as the precursor with deionized water, the volume ratio of water glass and deionized water is 1:1, stir for 10 minutes to obtain a uniformly mixed solution;

[0032] 2) Pass the solution obtained in step 1) through an ion exchange column equipped with a hydrogen-type cation exchange resin to remove Na+ ions and other impurity cations in the solution, while reducing the pH value of the solution to 2-3;

[0033] 3) Add ammonia water dropwise to the solution in step 2), adjust the pH value of the solution, control the gel time of the sol to 60 minutes, and place the sol in the sol storage tank of the integrated vacuum drying and pressure impregnation equipment;

[0034] 4) Put the expanded perlite in a vacuum tank, keep the normal pressure (vacuum pressure 0MPa), then heat it to a drying temperature of 60°C, and dry the expanded perlite to a constant weight; ...

Embodiment 2

[0043] A preparation method of airgel expanded perlite, specifically comprising the steps of:

[0044] 1) Mix water glass as the precursor with deionized water, the volume ratio of water glass and deionized water is 1:1, stir for 10 minutes to obtain a uniformly mixed solution;

[0045] 2) Pass the solution obtained in step 1) through an ion exchange column equipped with a hydrogen-type cation exchange resin to remove Na in the solution + ions and other impurity cations, while reducing the pH value of the solution to 2-3;

[0046] 3) Add ammonia water dropwise to the solution in step 2), adjust the pH value of the solution, control the gel time of the sol to 60 minutes, and place the sol in the sol storage tank of the integrated vacuum drying and pressure impregnation equipment;

[0047] 4) Put the expanded perlite in a vacuum tank, evacuate to -0.04MPa, then heat to a drying temperature of 100°C, and dry the expanded perlite to constant weight;

[0048] 5) Continue to evacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com