Anti-alkali-efflorescence sulphoaluminate cement product and preparation method thereof

A technology of sulphoaluminate cement and alkali sulphoaluminate, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as poor anti-permeability, poor corrosion resistance, and affecting appearance. Achieve the effect of strong water resistance, smooth outer surface, and not easy to return to alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

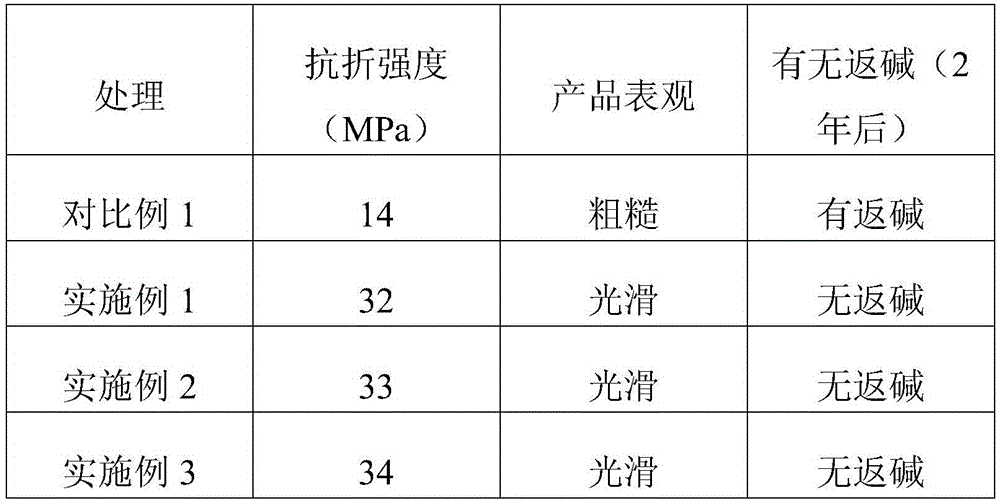

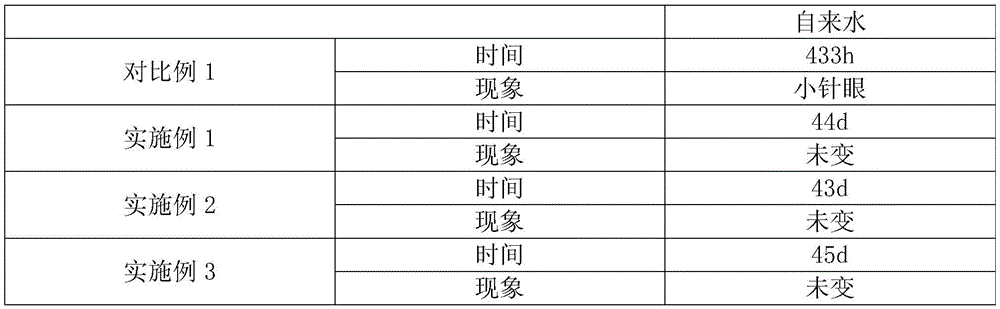

Examples

Embodiment 1

[0022] An anti-alkali sulphoaluminate cement product, comprising the following components by weight: 50 parts of sulphoaluminate cement, 8 parts of fly ash, 7 parts of silica fume, 8 parts of glass fiber, 30 parts of water, 2 parts of coagulant, 3 parts of water-retaining agent, 3 parts of thickener, 5 parts of ubiquinol inhibitor; described retarder is phosphogypsum; described water-retaining agent is methyl glucose laurate; described thickener The thickening agent is terpineol; and the ubiquinol inhibitor is thiodiethanol.

[0023] The preparation method of the anti-return alkali sulfoaluminate cement product comprises the following steps:

[0024] (1) Add sulfoaluminate cement, fly ash, silica fume and glass fiber into water and stir for 2 minutes;

[0025] (2) Then add water-retaining agent, thickener, and efflorescence inhibitor, stir for 1 minute, and let stand for 5 minutes;

[0026] (3) Then add the retarder, stir for 1min, send it to the production workshop of the r...

Embodiment 2

[0028] An anti-alkali sulfoaluminate cement product, comprising the following components by weight: 80 parts of sulfoaluminate cement, 15 parts of fly ash, 12 parts of silica fume, 12 parts of glass fiber, 90 parts of water, slow 5 parts of coagulant, 5 parts of water-retaining agent, 5 parts of thickener, 8 parts of ubiquinol inhibitor; described retarder is aminotrimethylene phosphonic acid; described water-retaining agent is γ-polyglutamic acid; Described thickener is coconut oil monoethanolamide; Described ubiquinol inhibitor is sodium sulfite.

[0029] The preparation method of the anti-return alkali sulfoaluminate cement product comprises the following steps:

[0030] (1) Add sulfoaluminate cement, fly ash, silica fume and glass fiber into water and stir for 10 minutes;

[0031] (2) Then add water-retaining agent, thickener, and efflorescence inhibitor, stir for 1 min, and let stand for 10 min;

[0032] (3) Then add the retarder, stir for 2min, send it to the productio...

Embodiment 3

[0034] An anti-alkali sulphoaluminate cement product, comprising the following components by weight: 60 parts of sulphoaluminate cement, 10 parts of fly ash, 10 parts of silica fume, 10 parts of glass fiber, 60 parts of water, slow 3 parts of coagulant, 4 parts of water-retaining agent, 4 parts of thickener, 7 parts of efflorescence inhibitor; described retarder is alunite; described water-retaining agent is zinc sulfate; described thickener is propylene Acyloxyethyltrimethylammonium chloride; the pan-alkali inhibitor is bis(3-triethoxysilylpropyl) tetrasulfide.

[0035] The preparation method of the anti-return alkali sulfoaluminate cement product comprises the following steps:

[0036] (1) Add sulfoaluminate cement, fly ash, silica fume and glass fiber into water and stir for 8 minutes;

[0037] (2) Then add water-retaining agent, thickener, and efflorescence inhibitor, stir for 1 minute, and let stand for 8 minutes;

[0038] (3) Then add retarder, stir for 1.5min, send it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com