Waterborne damping coating for metro vehicles and preparation method of waterborne damping coating for metro vehicles

A damping coating, water-based technology, applied in the direction of anti-corrosion coatings, fire-proof coatings, epoxy resin coatings, etc., can solve the problems of low flame-retardant grade and high price, and achieve the improvement of quality and technical indicators, low oil absorption value and technical content high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

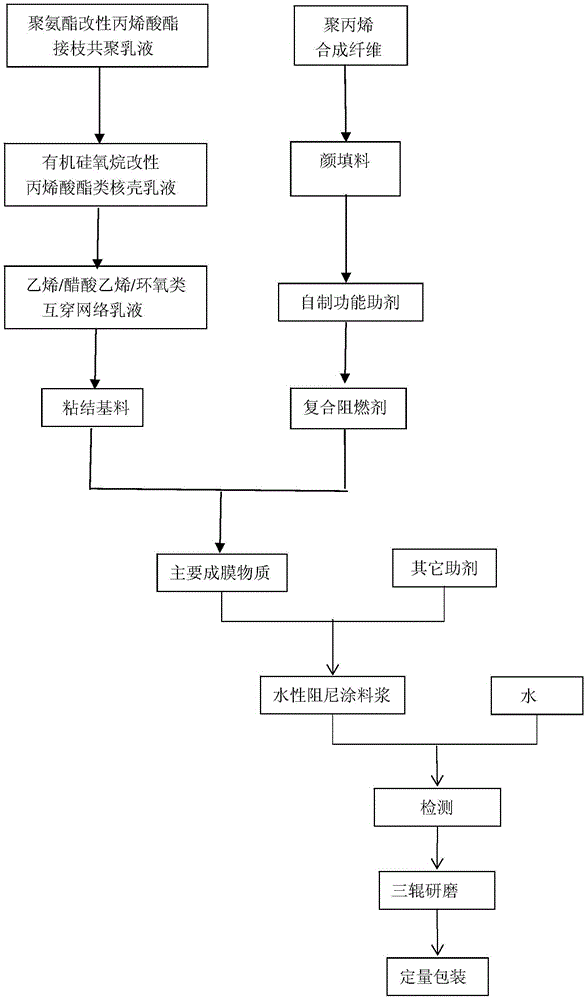

Method used

Image

Examples

preparation example Construction

[0030] A. Preparation of self-made multifunctional additives: four raw materials of ionic polyacrylate, amine neutralizer, substrate wetting agent and anti-corrosion and anti-fungal agent are added to the container tank in sequence according to the weight ratio, and the Put the container cylinder under the disperser, turn on the disperser, adjust the speed to 300-500 rpm, and stir for 20-30 minutes to make it evenly dispersed, and then get the self-made multifunctional additive; then remove the disperser, and the self-made The multi-functional auxiliary agent is sealed for use;

[0031] B. Preparation of composite flame retardant: spherical perlite powder, seven raw materials of nano-titanium dioxide, ammonium polyphosphate, water-based amino resin, organic phosphate, benzotriazole and hindered amine are added to the container in sequence by weight Put the container cylinder under the disperser, turn on the disperser, adjust the rotation speed to 300-500 rpm, and stir for 20-3...

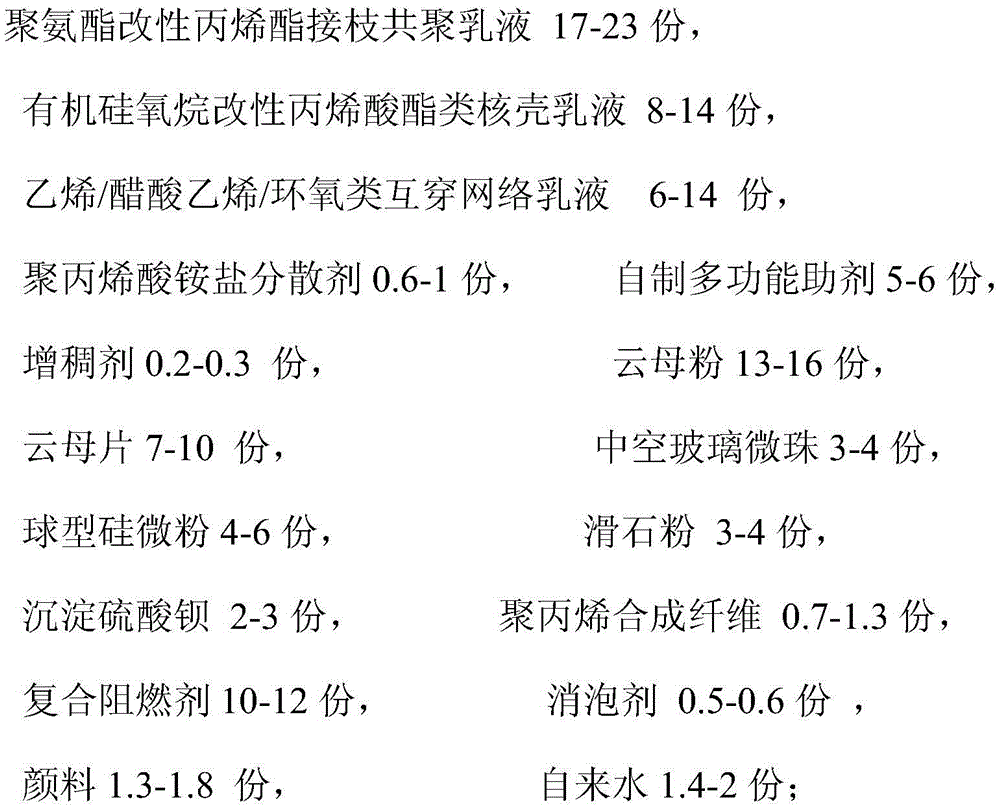

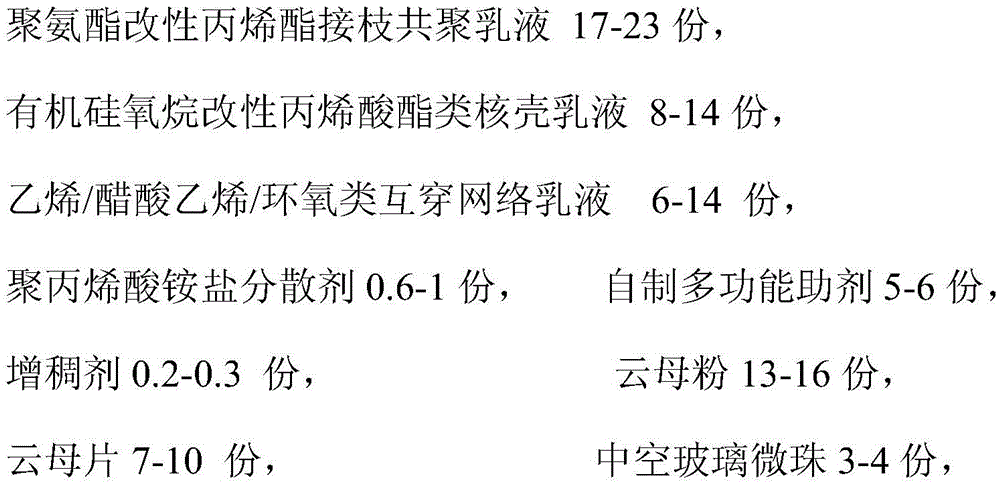

example

[0048]

[0049]

[0050] The test results of the above three examples all meet the technical requirements.

[0051] Note: Polyurethane modified acrylate graft copolymer emulsion, organosiloxane modified acrylate core-shell emulsion, ethylene / vinyl acetate / epoxy interpenetrating network emulsion are produced by Zhuzhou Rubber and Plastic Institute Synthetic Material Factory; The self-made multifunctional additives are made by Zhuzhou Hualian High-Tech Industrial Co., Ltd.; the thickener and defoamer are produced by Taiwan Deqian Company; the mica powder mica powder is produced by Chuzhou Gree Company in Anwei Province; factory; hollow glass microspheres are produced by Shanghai Huijingya Nano New Materials Co., Ltd.; spherical perlite powder is produced by Zhongxin Perlite Thermal Insulation Building Materials Factory in Xinyang City, Henan Province; talc powder is produced by Guangxi Longguang Talc Development Co., Ltd.; precipitation Barium sulfate was produced by Guizh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com