Enrichment-thermal desorption-chromatography separating unit

A chromatographic separation and separation device technology, which is applied in the field of gas sample rapid enrichment-thermal desorption-chromatographic separation device, can solve the problem of difficulty in taking into account analysis speed and separation efficiency, reducing the ability of a chromatographic column to resolve peaks, and the initial enrichment temperature. Long time and other problems, to achieve the effect of improving the thermal analysis speed, high temperature programming rate, and reducing the analysis cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

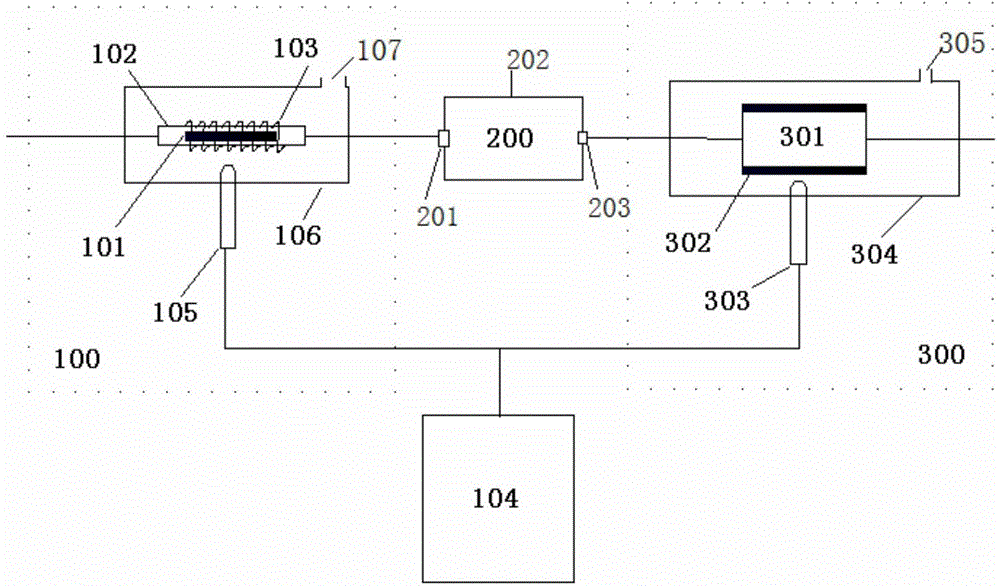

[0040] A kind of enrichment-thermal analysis-chromatographic separation device, such as figure 1 As shown, it consists of an enrichment thermal desorption device 100 , a sampling device 200 , a separation device 300 and a cooling source 104 .

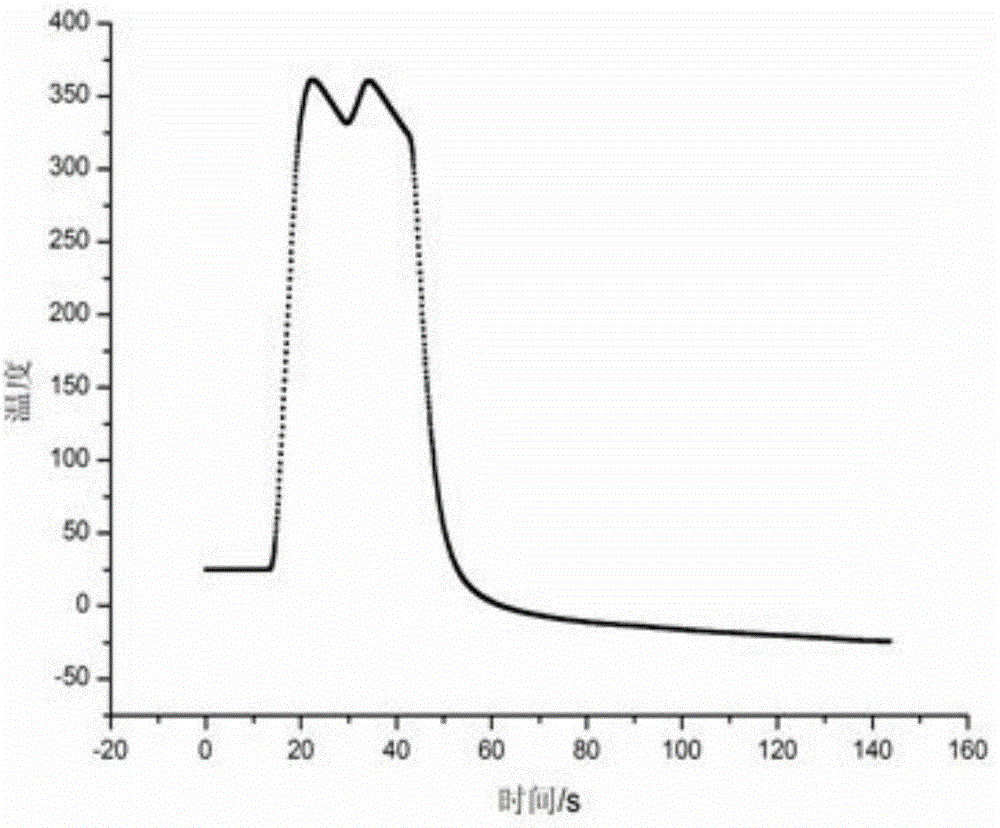

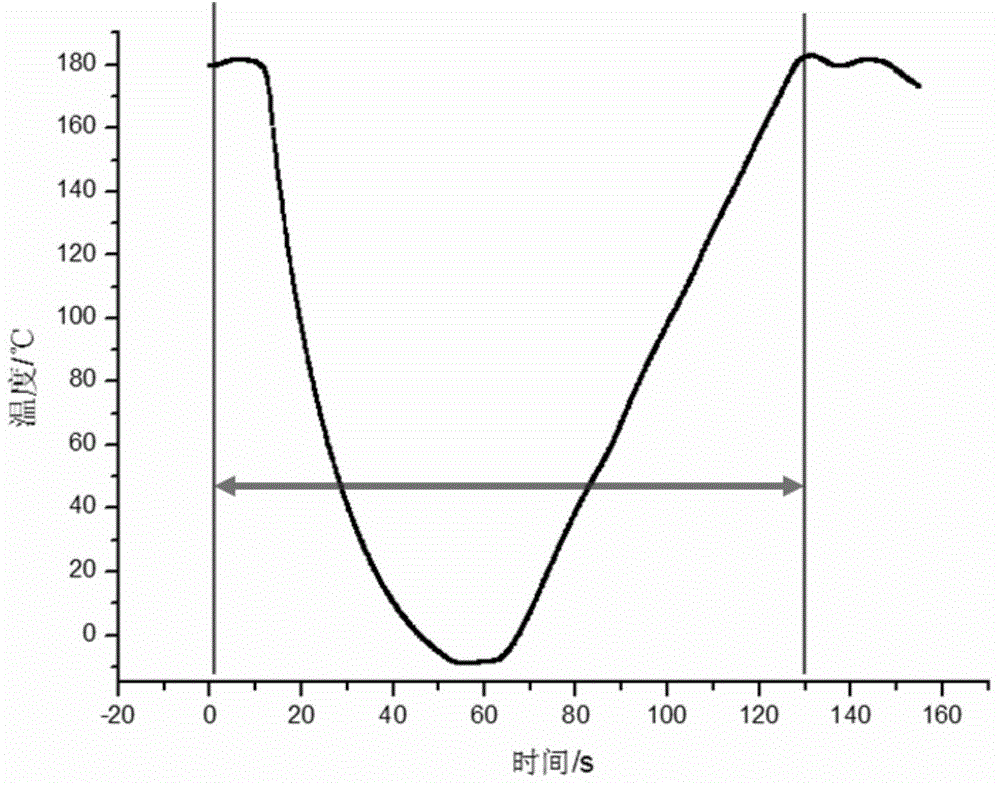

[0041] The enrichment thermal desorption device 100 is composed of an adsorption tube 102 , a heating wire 103 , a first cooling cover 106 and a first cooling nozzle 105 . The adsorption tube 102 is a quartz tube with a main body diameter of 3 mm, which is filled with an adsorbent 101, which is a mixture of 5 mg of graphitized carbon black and 4 mg of Carbosieve SIII. The adsorption tube 102 is wound with a heating wire 103. The heating wire 103 is a Ni-Cr alloy with a wire diameter of 0.4 mm, a resistance of 10 ohms, and a heating rate of 40° C. / s. Both ends of the adsorption tube 102 are respectively connected to the sample source and the sampling device 200 ; the end of the adsorption tube 102 connected to the sampling device 200 ha...

Embodiment 2

[0049] The device as described in Embodiment 1, wherein the sampling device 200 is a three-way two-position solenoid valve.

Embodiment 3

[0051] The device as described in Example 1, wherein the adsorption tube 102 is a stainless steel tube with an inert inner wall, and the adsorbent 101 is 10 mg carbon molecular sieve TDX-1. The sampling device 200 and its connecting pipes are in room temperature environment. The device can realize rapid enrichment-thermal analysis-chromatographic separation of low-carbon hydrocarbons (such as ethane, ethylene, propane, etc.), and the entire analysis period is less than 2 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com