Serial thermal printing light emitting display

A display and thermal transfer technology, applied in the direction of electric solid devices, circuits, electrical components, etc., can solve the difficulty of illuminant lattice, the lack of thermal transfer temperature gradient viscosity gradient in the transfer layer, and the high particle size of inorganic electroluminescent powder. Diameter and other problems to achieve reliable transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

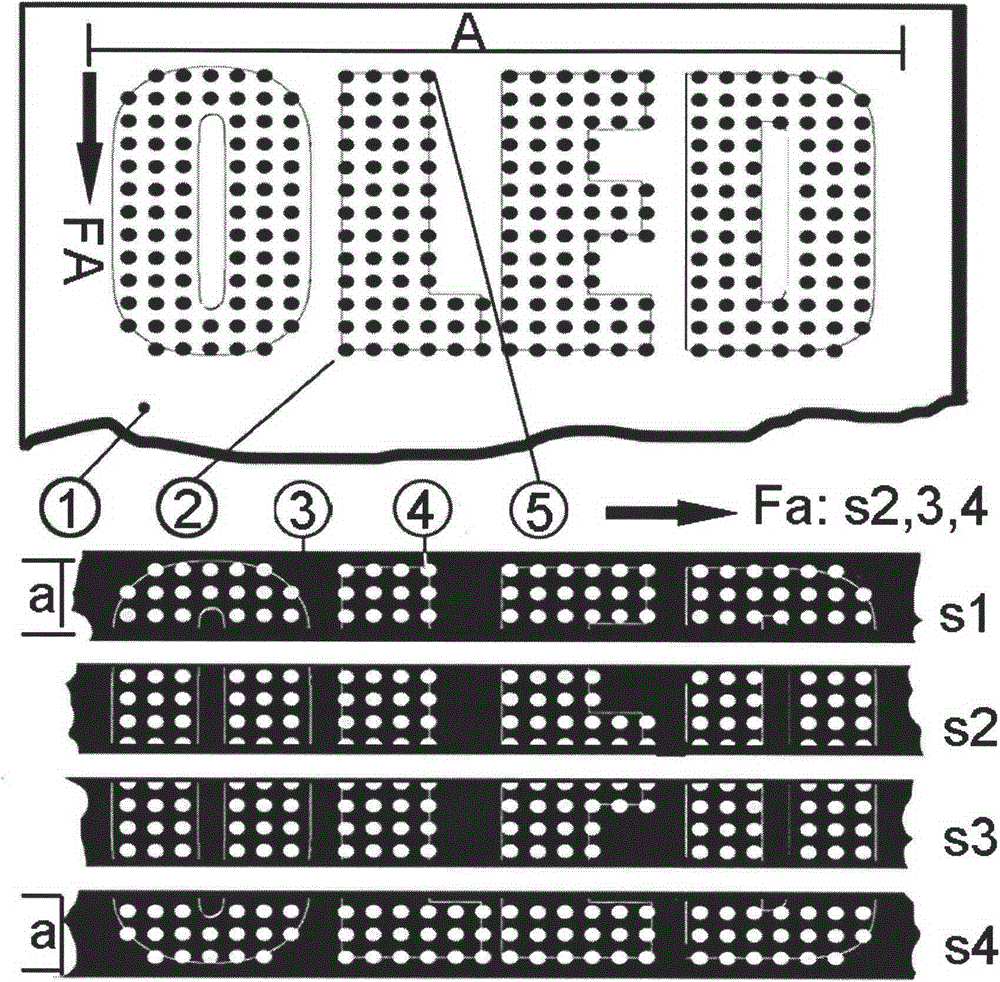

[0075] 1.0 Example target: Serial thermal transfer flexible full-color display (screen) (STP-FOLED)

[0076] 2.0 Product structure: PET(Panel) / Anode<PSTFT / HTL / RGBEML&IFL / ETL / Cathode / PET(Blind)

[0077] 3.0 drive mode: active matrix OLED drive display system [301] (TCL, LG, etc.)

[0078] 4.0 Display panel: BOPET, thickness 75-100μm / Anode<PSTFT [401] (Outsourcing, such as Taiwan Qijing Optoelectronics. Choose the largest area, the highest number of lines. When the resolution of the image number circuit is not enough, choose multilayer LTPSTFT, multilayer ITO Technology. The production of displays with ITO glass plates is similar to this embodiment).

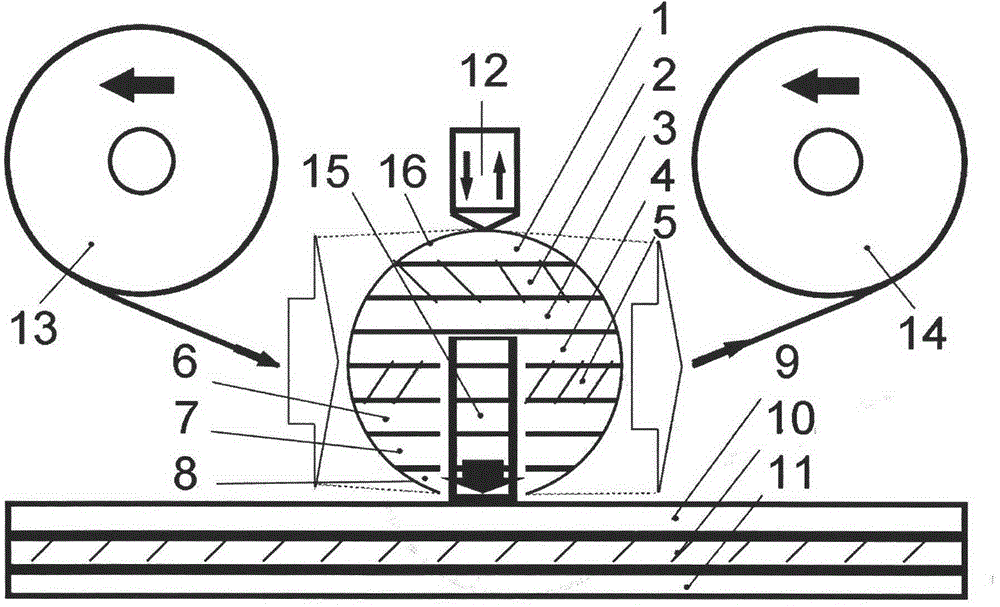

[0079] 5.0 Production of display cover / cathode / electron transport layer:

[0080] 5.1BOPET, thickness 50-75μm, width 900-1000mm; vacuum evaporation Mg / Ag, thickness 0.15μm; then vacuum evaporation Ag, thickness 0.05μm, [501].

[0081] 5.2 Manufacturing of electron transport layer coatings: 3.0-5.0% Butyl-PBD, 2.0-3.0% acrylates, 2.0-3.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com