Ready-to-eat crisps containing vegetables and minced fillet and preparation method of ready-to-eat crisps containing vegetables and minced fillet

A technology of surimi and crisps, applied in the field of ready-to-eat vegetable surimi chips and its preparation, can solve the problems of poor taste and unbalanced nutrition of the chips, avoid rough appearance, help fat decomposition, and have a soft and soft texture slippery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of ready-to-eat vegetable surimi chips is based on 1kg of surimi, and then adds 3.0wt% salt, 40wt% corn starch, 12wt% defatted soybean protein powder, 40wt% pumpkin puree, 18wt% fungus vegetables, 15wt% chrysanthemum , 2.0wt% white granulated sugar and 15wt% water from eight raw materials.

[0032] The specific steps are:

[0033] (1) Pretreatment of raw and auxiliary materials: 1kg of frozen silver carp surimi is thawed in a 5 ℃ environment, and the thawed surimi is placed in a crusher for 4 minutes; the pumpkin is removed from the melon, skin and pulp, washed and drained. Dried and cut into small pieces, steamed and smashed into mud, weighed as needed; washed the fungus and chrysanthemum, chopped and set aside;

[0034] (2) Salt beat: add 3.0wt% salt to the surimi treated in step (1), continue to beat for 7min to fully dissolve the salt-soluble protein, and obtain a viscous surimi raw material;

[0035] (3) Mixing ingredients: 40wt% corn starch, 12wt% defatte...

Embodiment 2

[0041] A kind of ready-to-eat vegetable surimi chips is based on 1kg of surimi, and is further added with 3.0wt% salt, 45wt% corn starch, 10wt% defatted soybean protein powder, 35wt% pumpkin puree, 15wt% fungus and 20wt% chrysanthemum , 2.0wt% white sugar and 18wt% water from eight raw materials.

[0042] The specific steps are:

[0043](1) Pretreatment of raw and auxiliary materials: 1kg of frozen silver carp surimi is thawed in an environment of 10°C, and the thawed surimi is placed in a masher for 3 minutes; the pumpkin is removed from the melon, skin and pulp, washed and drained. Dried and cut into small pieces, steamed and smashed into mud, weighed as needed; washed the fungus and chrysanthemum, chopped and set aside;

[0044] (2) Salt beat: add 3.0wt% salt to the surimi processed in step (1), continue to beat for 5min to fully dissolve the salt-soluble protein, and obtain a viscous surimi raw material;

[0045] (3) Mixtures: 45wt% corn starch, 10wt% defatted soybean pr...

Embodiment 3

[0051] A kind of ready-to-eat vegetable surimi chips is based on 1kg of surimi, and then adds 2.0wt% salt, 40wt% corn starch, 12wt% defatted soybean protein powder, 40wt% pumpkin puree, 18wt% fungus vegetables, 15wt% chrysanthemum , 2.5wt% white granulated sugar and 25wt% water from eight raw materials.

[0052] The specific steps are:

[0053] (1) Pretreatment of raw and auxiliary materials: 1kg of frozen silver carp surimi is thawed in a 6°C environment, and the thawed surimi is placed in a masher for 5 minutes; the pumpkin is removed from the melon, skin and pulp, washed and drained. Dried and cut into small pieces, steamed and smashed into mud, weighed as needed; washed the fungus and chrysanthemum, chopped and set aside;

[0054] (2) Salt pounding: adding 2.0 wt% salt to the surimi processed in step (1), and pounding for 5 minutes to fully dissolve the salt-soluble protein to obtain a viscous surimi raw material;

[0055] (3) Mixing ingredients: 40wt% cornstarch, 12wt% ...

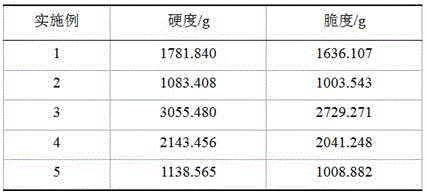

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crispness | aaaaa | aaaaa |

| Crispness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com