Compound liquid desulfurizing agent and application thereof

A desulfurizer and liquid mixing technology, applied in gas fuel, gas treatment, combustible gas purification, etc., can solve the problems of low sulfur capacity, easy degradation, slow reaction rate, etc., and achieve the effect of high selective absorption and fast absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A compound liquid desulfurizer, comprising the following raw materials in weight percentage: 45% of hindered amine absorbent (weight ratio of aminoethoxyethanol to methyldiethanolamine 5:1), 4% of activator (ethylene glycol mono Ethyl ether and ethylene glycol dimethyl ether weight ratio 1:1), defoamer (methyl silicone oil) 0.1%, pH corrosion inhibitor 2.9% (2-amino-2-methyl-1-propanol and Na 2 CO 3 / NaHCO 3 The weight ratio is 5:1) and the balance of water. After dissolving each raw material in water, stir evenly to obtain the compound liquid desulfurizer, which is marked as CCJ-3# desulfurizer.

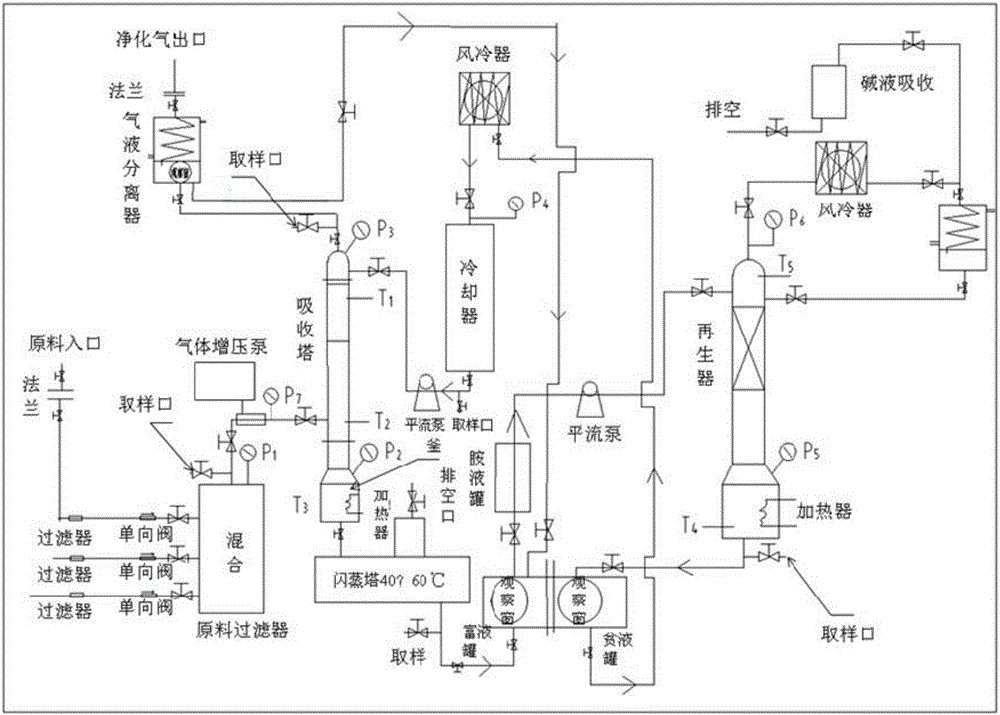

[0032] Test experiment: The CCJ-3# desulfurizer obtained in Example 1 is used to remove high-sulfur gas, at 40°C, normal pressure -70Mpa, CCJ-3# desulfurizer volume 500ml, gas-liquid ratio 1:300(m 3 :m 3 ) under the condition of using figure 1 The device and process remove sulfur in high-sulfur gas, and CH in high-sulfur gas 4 90%, H 2 S concentration 5%, organic mercap...

Embodiment 2

[0038] A compound liquid desulfurizer, comprising the following raw materials in weight percentage: 45% of hindered amine absorbent (aminoethoxyethanol), 7% of activator (ethylene glycol monoethyl ether and aminoethylpiperazine weight ratio 1 :3), defoamer (methyl silicone oil) 0.1%, pH corrosion inhibitor 1.9% (2-amino-2-ethyl-1,3-propanediol and sodium borate / boric acid weight ratio 6:1) and the balance water, each raw material is dissolved in water, and stirred evenly to obtain the compound liquid desulfurizer, marked as CCJ-4# desulfurizer.

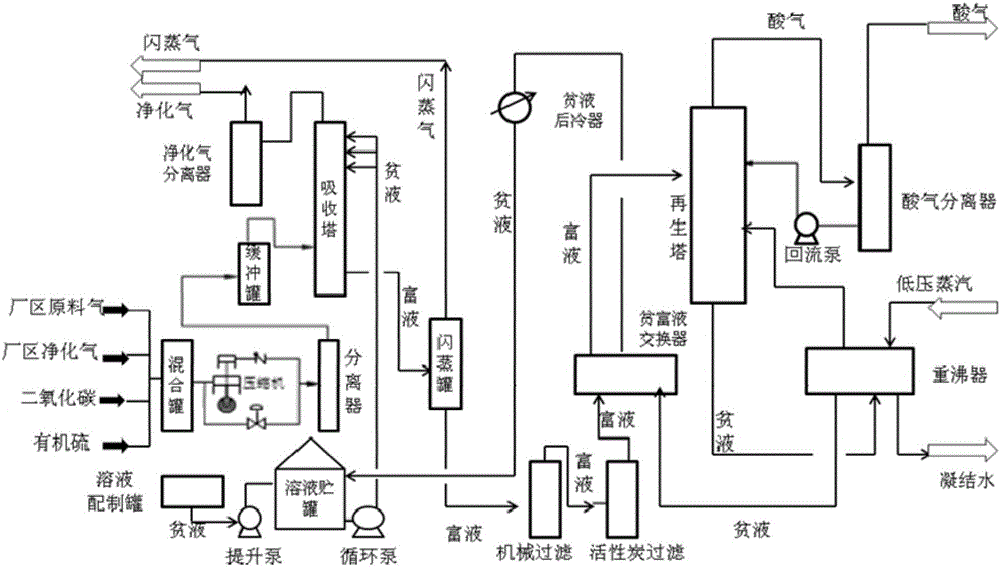

[0039] Test experiment: The CCJ-4# desulfurizer obtained in Example 2 is used to remove high-sulfur and high-carbon natural gas. At 40°C, 4.8-7.2Mpa, the volume of CCJ-4# desulfurizer is 500ml, and the gas-liquid ratio is 1:300- 600(m 3 :m 3 ) under the condition of using figure 2 The device and process remove sulfur in high-sulfur and high-carbon natural gas, and CH in high-sulfur gas 4 90%, CO 2 3.8%, H 2 S concentration 5.7%...

Embodiment 3

[0045] A compound liquid desulfurizer, comprising the following raw materials in weight percentage: 45% of hindered amine absorbent (aminoethoxyethanol), 8% of activator (ethylene glycol monoethyl ether and N-hydroxyethylpiperazine weight Ratio 1:2), defoamer (methyl silicone oil) 0.1%, pH corrosion inhibitor 3.5% (weight ratio of butyl ethanolamine to sodium borate / boric acid 5:1) and the rest of water, after the raw materials are dissolved in water , and stir evenly to prepare the CCJ-2# desulfurizer described in the present invention.

[0046] Test experiment: The CCJ-2# desulfurizer obtained in Example 3 is used to remove high-sulfur and high-carbon natural gas. At 40°C, 4.8-7.2Mpa, the volume of CCJ-4# desulfurizer is 5m 3 , gas-liquid ratio 1:350-600(m 3 :m 3 ) under the condition of using figure 2 The device and process remove sulfur in high-sulfur and high-carbon natural gas, and CH in high-sulfur gas 4 90%, CO 2 3.8%, H 2 S concentration 5.7%, organic sulfur 37...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com