Resourceful treatment method for chemical sludge

A treatment method and technology for chemical sludge, applied in the field of chemical sludge recycling, can solve the problems of high operation cost, long investment recovery period, lack of land resources, etc., to save treatment cost, low operation cost and process investment. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

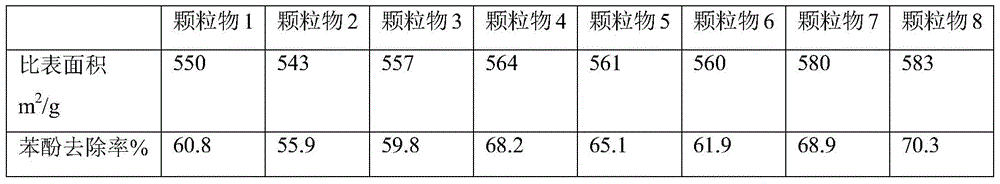

Examples

Embodiment 1

[0013] Step 1) Divide the sludge obtained after the paper mill sewage treatment into two parts, when the mass ratio between the two parts is 1:1.2.

[0014] Step 2) A part of the sludge is dried to constant weight, pulverized after cooling, sieved with 12 meshes, and then ZnCl with a concentration of 1 mol / L is added 2 Solution, Sludge and ZnCl 2 The mass ratio of the solution is 1:1. After immersion at 60°C for 4 hours, separation, and drying of the solid, the temperature was raised to 400°C at a rate of 45°C / min in a muffle furnace, maintained for 60 minutes, and a porous solid was obtained after cooling.

[0015] Step 3) Add sulfuric acid with a concentration of 96% to another part of the sludge, stir continuously until the pH value is 1, add hydrogen peroxide with a concentration of 30%, and at the same time pass air, and the air flow is 7m 3 / h, after 2 hours, filter and take the filtrate.

[0016] Step 4) The porous solid obtained in step 2) is placed in the filtrate ...

Embodiment 2

[0018] Step 1) Divide the sludge obtained after the paper mill sewage treatment into two parts, when the mass ratio between the two parts is 1:1.5.

[0019] Step 2) A part of the sludge is dried to constant weight, pulverized after cooling, sieved with 12 meshes, and then added with ZnCl with a concentration of 1.5 mol / L 2 Solution, Sludge and ZnCl 2 The mass ratio of the solution is 1:1.5. After immersion at 70°C for 8h, separation, and drying of the solid, the temperature was raised to 400°C at a rate of 50°C / min in a muffle furnace, maintained for 70min, and a porous solid was obtained after cooling.

[0020] Step 3) Add sulfuric acid with a concentration of 98% to another part of the sludge, stir continuously until the pH value is 2, add hydrogen peroxide with a concentration of 40%, and at the same time pass air, and the air flow is 10m 3 / h, after 5 hours, filter and take the filtrate.

[0021] Step 4) The porous solid obtained in step 2) is placed in the filtrate obt...

Embodiment 3

[0023] Step 1) Divide the sludge obtained after the paper mill sewage treatment into two parts, when the mass ratio between the two parts is 1:1.2.

[0024] Step 2) A part of the sludge is dried to constant weight, pulverized after cooling, sieved with 12 meshes, and then added with ZnCl with a concentration of 1.5 mol / L 2 Solution, Sludge and ZnCl 2 The mass ratio of the solution is 1:1.5. After immersion at 70°C for 8h, separation, and drying of the solid, the temperature was raised to 400°C at a rate of 50°C / min in a muffle furnace, maintained for 70min, and a porous solid was obtained after cooling.

[0025] Step 3) Add sulfuric acid with a concentration of 96% to another part of the sludge, stir continuously until the pH value is 1, add hydrogen peroxide with a concentration of 30%, and at the same time pass air, and the air flow is 7m 3 / h, after 2 hours, filter and take the filtrate.

[0026] Step 4) The porous solid obtained in step 2) is placed in the filtrate obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com