Three dimensional ordered meso-porous Au-TiO2/IO-SiO2 film visible light photocatalyst and preparation method thereof

A photocatalyst, au-tio2 technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. Catalytic performance, enhancement of absorption rate, effect of reducing recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

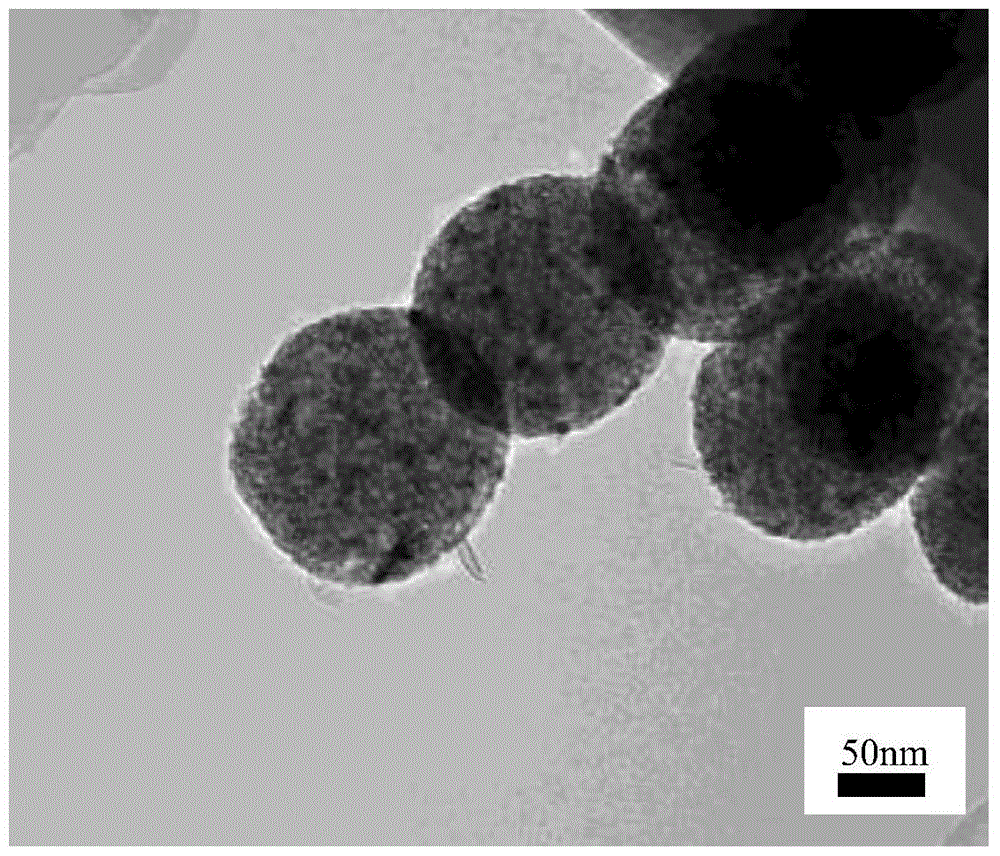

[0027] Three-dimensional ordered mesoporous Au-TiO 2 / IO-SiO 2 The preparation method of catalyst, step is as follows:

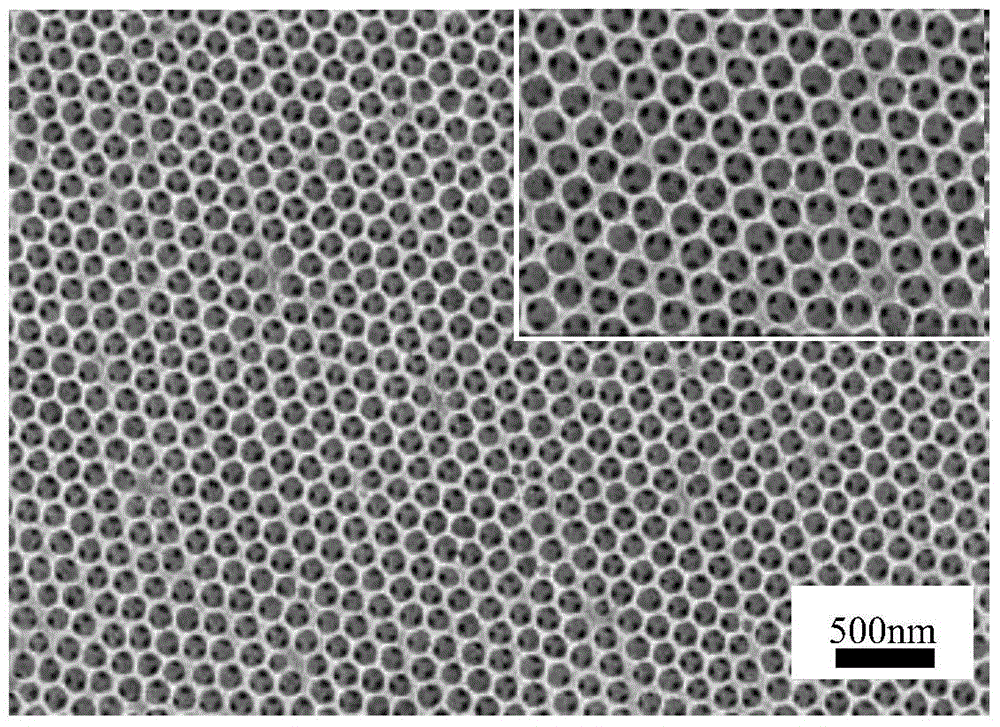

[0028](1) Synthesize monodisperse polystyrene microspheres (PS) by soap-free emulsion polymerization: 137ml of absolute ethanol and 53ml of deionized water are added in a four-necked flask, and argon is introduced into the device as a protective gas, and the stirring rate is The temperature is 300rmp / min, and the temperature of the oil bath is raised slowly. When the temperature in the device was stabilized at 71° C., 10 ml of styrene after vacuum distillation was added, and then 0.18 g of potassium persulfate dissolved in 10 ml of deionized water was added as an initiator. After 24 hours of reaction, stop heating, and after cooling, remove impurities and large particles by suction filtration with a glass fiber membrane to obtain a polystyrene suspension with uniform particle size, the particle size is about 370nm.

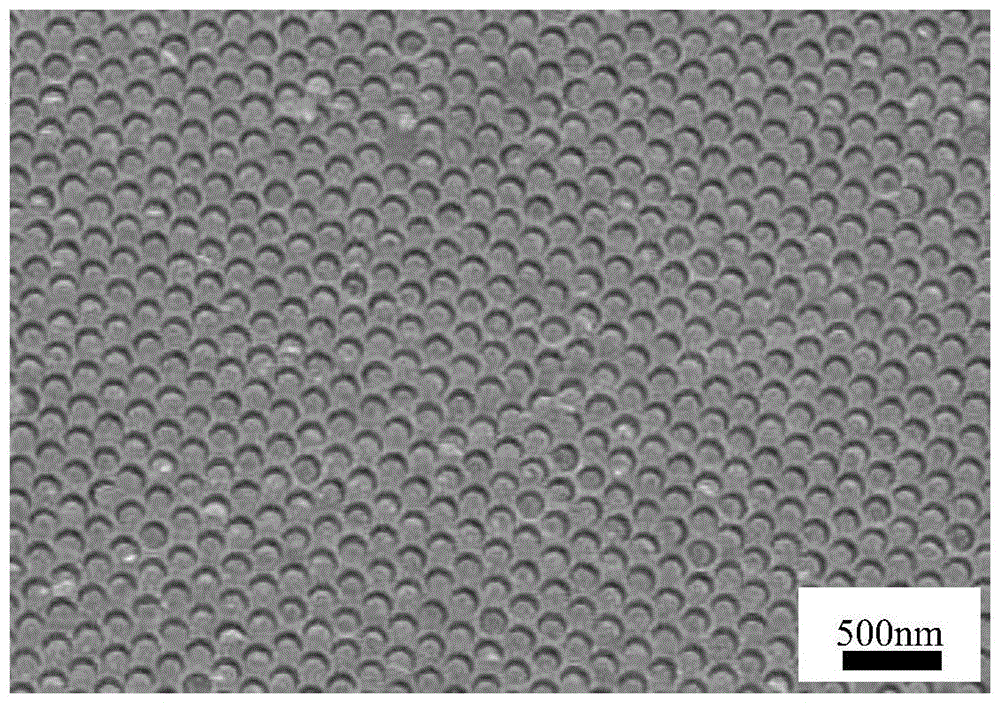

[0029] (2) Preparation of SiO by co-as...

Embodiment 2

[0034] Three-dimensional ordered mesoporous Au-TiO 2 / IO-SiO 2 The preparation method of catalyst, step is with embodiment 1, difference is: used HAuCl 4 4H 2 The mass of O is 0.0067g, and the degradation rate of tetracycline hydrochloride reaches 85.4% after visible light irradiation for 2 hours. 0.0134g, the degradation rate of tetracycline hydrochloride reached 79.4% after visible light irradiation for 2 hours.

Embodiment 3

[0036] Three-dimensional ordered mesoporous Au-TiO 2 / IO-SiO 2 The preparation method of catalyst, step is with embodiment 1, difference is: used HAuCl 4 4H 2 The mass of O is 0.01g, and the degradation rate of tetracycline hydrochloride reaches 92% after visible light irradiation for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com