Recycling method for SAPO-34 molecular-sieve synthesized mother liquid

A SAPO-34, a technology for synthesizing mother liquor, which is applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems affecting the performance of molding catalysts, difficult to use mother liquor at one time, and unfavorable industrial operation, etc., so as to reduce the synthesis Cost, high crystallinity, and the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

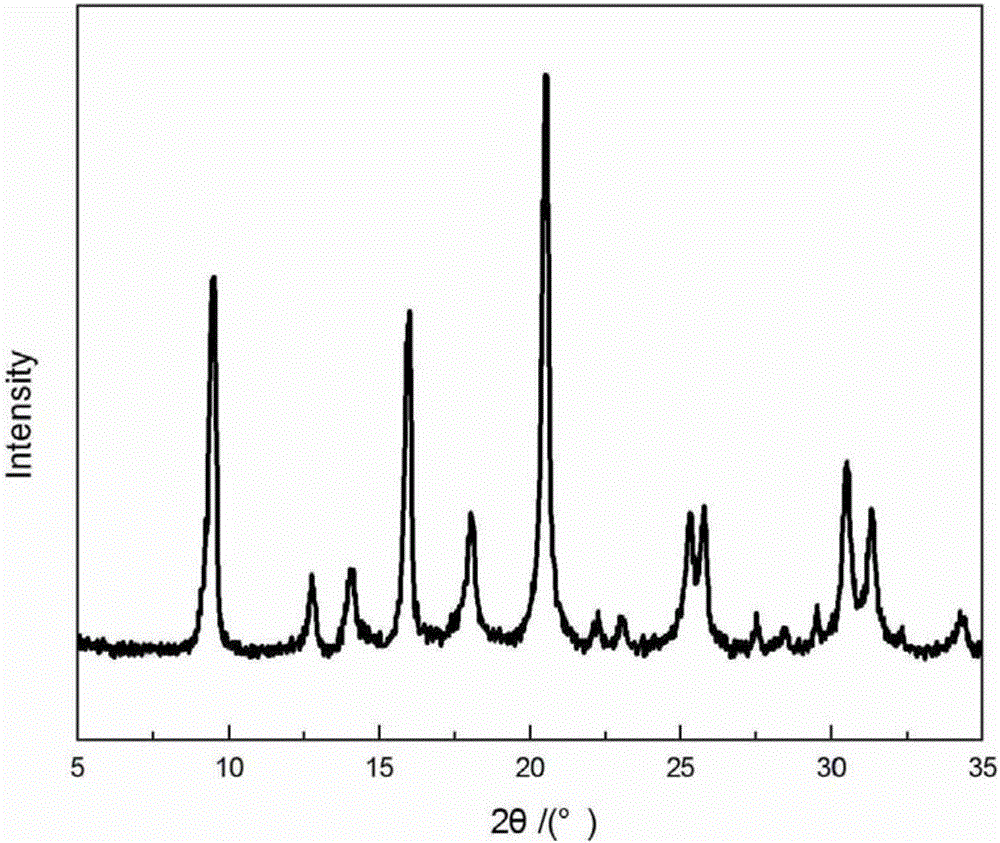

[0029] According to the ratio of raw materials 0.2SiO 2 :1.0Al 2 o 3 :1.0P 2 o 5 :2.0TEAOH:50H 2 O was sequentially added deionized water, pseudoboehmite, TEAOH, phosphoric acid, and silica sol, and stirred thoroughly to prepare an initial gel, which was then placed in a polytetrafluoroethylene-lined high-pressure crystallization kettle, and crystallized at 170°C for 24h. The solid product was separated, the mother liquor was recovered, the solid product was washed with deionized water until neutral, and dried at 110°C for 24 hours to obtain the original powder of SAPO-34 molecular sieve, marked as S-1. The X-ray diffraction analysis results are shown in the accompanying drawings, and the relative crystallinity is defined as 100%.

Embodiment 2

[0031] According to the ratio of raw materials 0.5SiO 2 :1.0Al 2 o 3 :1.0P 2 o 5 :0.5TEAOH:2.5TEA:90H 2 O Add deionized water, aluminum hydroxide, TEAOH, TEA, phosphoric acid, and ethyl orthosilicate in turn, stir well to prepare the initial gel, then put it into a polytetrafluoroethylene-lined high-pressure crystallization kettle, and crystallize at 150°C 36h. The solid product was separated, the mother liquor was recovered, the solid product was washed with deionized water until neutral, and dried at 110° C. for 24 hours to obtain the original powder of SAPO-34 molecular sieve, marked as S-2. X-ray diffraction analysis confirmed that the obtained solid product was SAPO-34 molecular sieve, and its relative crystallinity was 95%.

Embodiment 3

[0033] The mother liquor collected in Example 1 was concentrated, and the volume of the concentrated mother liquor was 25% of the recovered mother liquor volume. Use the formula in Example 1 to configure the initial gel, crystallize at 170°C for 24 hours, add the above-mentioned concentrated mother liquor, the addition amount is 6 times the mass of the initial gel, stir evenly and crystallize at 160°C for 30 hours, the solid product is separated, and the mother liquor After recovery, the solid product was washed with deionized water until it was neutral, and dried at 110°C for 24 hours to obtain the original powder of SAPO-34 molecular sieve, which was marked as S-3. X-ray diffraction analysis confirmed that the obtained solid product was SAPO-34 molecular sieve, and its relative crystallinity was 110%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com