Black alumina ceramics, manufacturing method thereof, alumina ceramic device

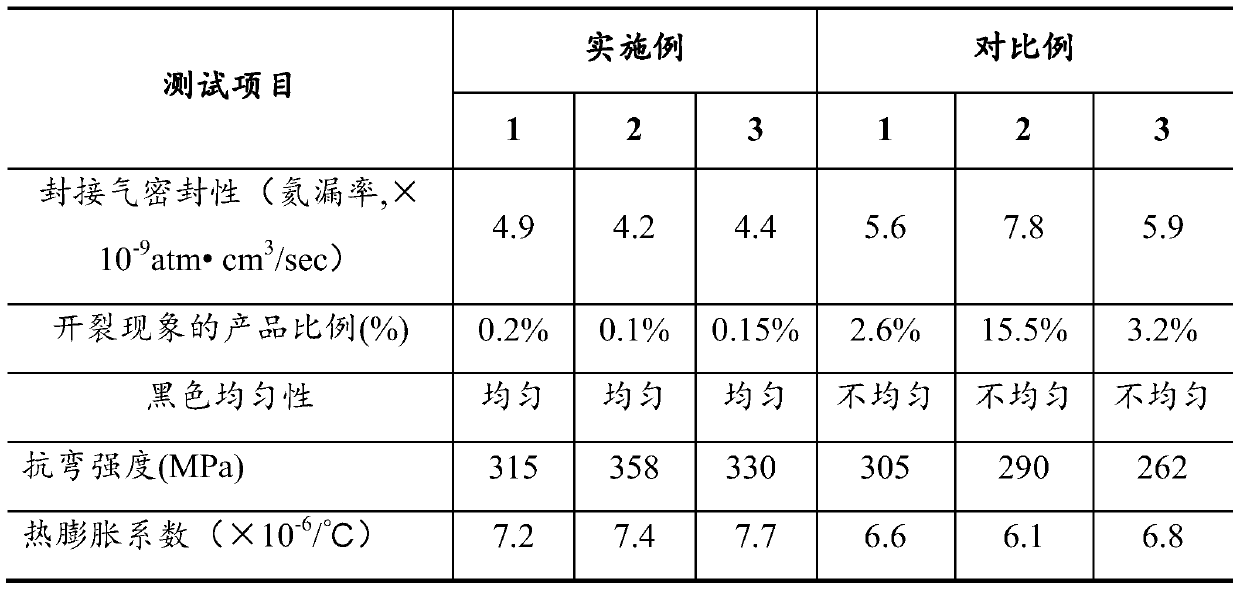

A technology of black alumina and ceramics, applied in the field of ceramic materials, can solve the problems of large differences in thermal expansion coefficients of glass products, large differences in thermal expansion coefficients, uneven color, etc., to improve sealing quality and stability, dimensional stability, uniform color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] On the other hand, the embodiment of the present invention also provides a preparation method of the above-mentioned black alumina ceramic of the embodiment of the present invention. In one embodiment, the method for preparing black alumina ceramics according to the embodiment of the present invention includes the following steps:

[0034] Step S01: Weigh the raw materials of each component according to the following components contained in the black alumina ceramics:

[0035] Al 2 o 3 90%-95%, black toner 2.5%-9%, sintering aid 1%-2.5%;

[0036] Step S02: performing ball milling on each component raw material weighed in step S01, followed by drying and sieving;

[0037]Step S03: pre-sintering and pulverizing the mixed raw materials that have been sieved in step S02, and then molding them, and performing pressure sintering in a protective atmosphere to obtain black alumina ceramics.

[0038] Specifically, in the above step S01, the black toner is used to impart blac...

Embodiment 1

[0051] This embodiment 1 provides a black alumina ceramic and its preparation method. The black alumina ceramic contains the following components by mass percentage:

[0052] 90%Al 2 o 3 , 3% Fe 2 o 3 , 3% NiO, 3% Ti 4 o 7 , 0.5%Na 2 O and 0.5% K 2 O.

[0053] The preparation method of the black alumina ceramics is as follows:

[0054] S11: Weigh the raw materials of each component according to the above-mentioned mass percentages contained in the black alumina ceramics in Example 1;

[0055] S12: Perform ball milling on the weighed raw materials of each component, and then perform drying and sieving; wherein, the ball milling process is to mix the weighed raw materials of each component on a planetary ball mill for 4 hours, and the speed of the ball mill is 200 rpm min, the drying process is to dry in a vacuum drying oven for 10 hours, and the sieving process is to sieve powder with a 100-mesh stainless steel screen;

[0056] S13: Put the sieved mixed raw material ...

Embodiment 2

[0058] This embodiment 2 provides a black alumina ceramic and its preparation method. The black alumina ceramic contains the following components by mass percentage:

[0059] 93% Al 2 o 3 , 2% Fe 2 o 3 , 2% NiO, 0.5% Ti 4 o 7 , 1.25% Na 2 O and 1.25% K 2 O.

[0060] The preparation method of the black alumina ceramics is as follows:

[0061] S11: Weigh the raw materials of each component according to the above-mentioned mass percentages contained in the black alumina ceramics in Example 2;

[0062] S12: Perform ball milling on the weighed raw materials of each component, and then perform drying and sieving; wherein, the ball milling process is to mix the weighed raw materials of each component on a planetary ball mill for 8 hours, and the speed of the ball mill is 300 rpm min, the drying process is to dry in a vacuum drying oven for 18 hours, and the sieving process is to sieve powder with a 100-mesh stainless steel screen;

[0063] S13: Put the sieved mixed raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com