Preparation method of polyacrylonitrile fibers

A technology of polyacrylonitrile fiber and comonomer, which is applied in fiber processing, fiber chemical characteristics, spinning solution preparation, etc., can solve the problems of poor spinnability of spinning solution, high fiber breakage rate, low fiber strength, etc. Achieve the effect of reducing the probability of wire breakage, high fiber strength and low breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Preparation of stock solution: Add acrylonitrile, itaconic acid and methyl methacrylate to the polymerization kettle, then add initiator and dimethyl sulfoxide, react at a temperature of 40°C for 10 hours, and then remove Unreacted monomers and the bubbles generated by the reaction obtain the spinning dope, the initiator is azobisisoheptanonitrile, the mass ratio of acrylonitrile and comonomer is 98.5:1.5, and the mass percent of the initiator accounting for the total monomer is 0.08%, and the total monomer concentration is 15%. After filtration, high-performance polyacrylonitrile copolymer spinning stock solution is obtained. The spinning stock solution has a particle weight of 110,000, a molecular weight distribution of 2.0, and a viscosity of 90 Pa·S at 60°C. The spinning dope temperature was 60°C.

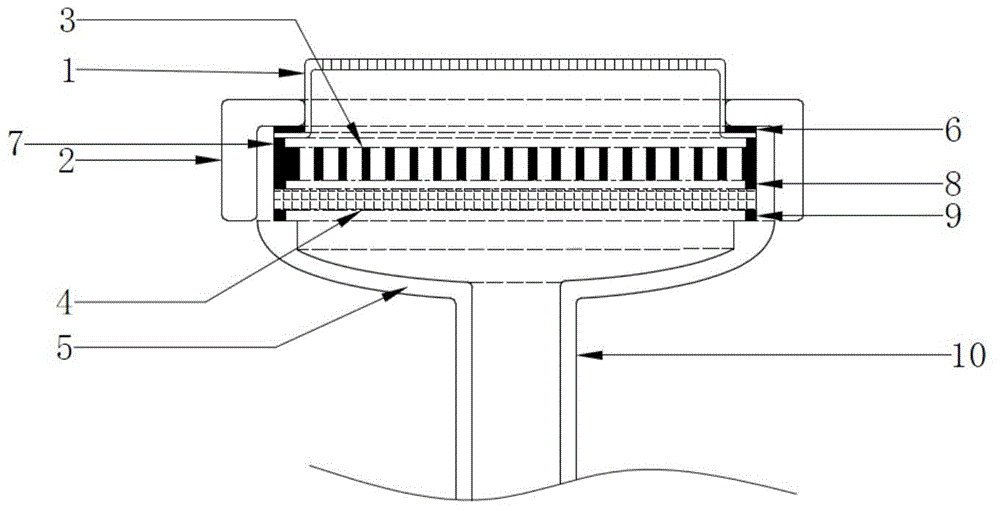

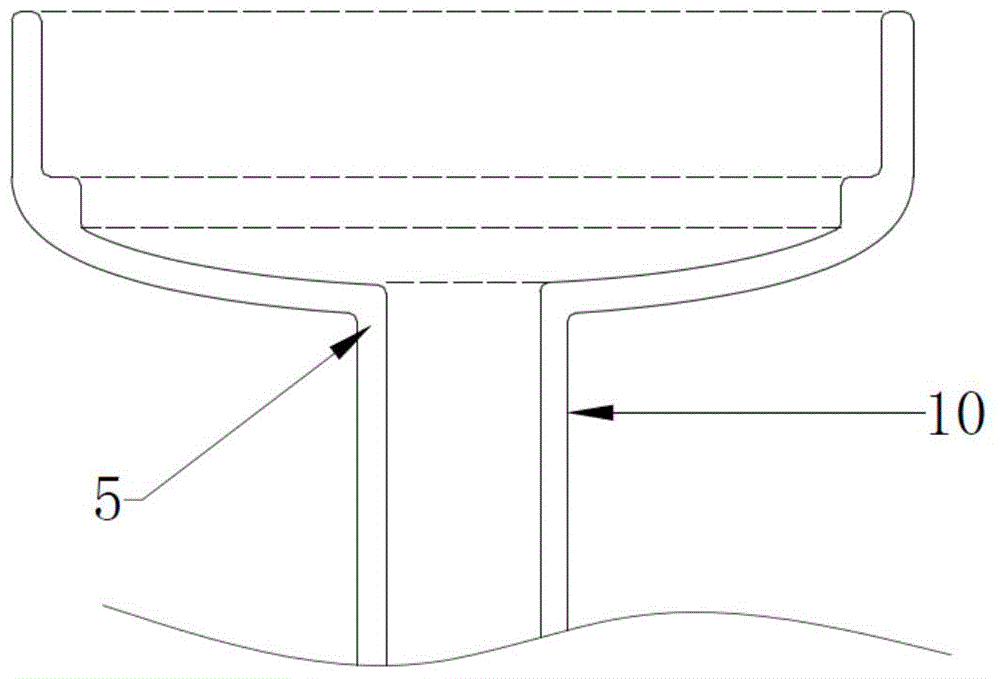

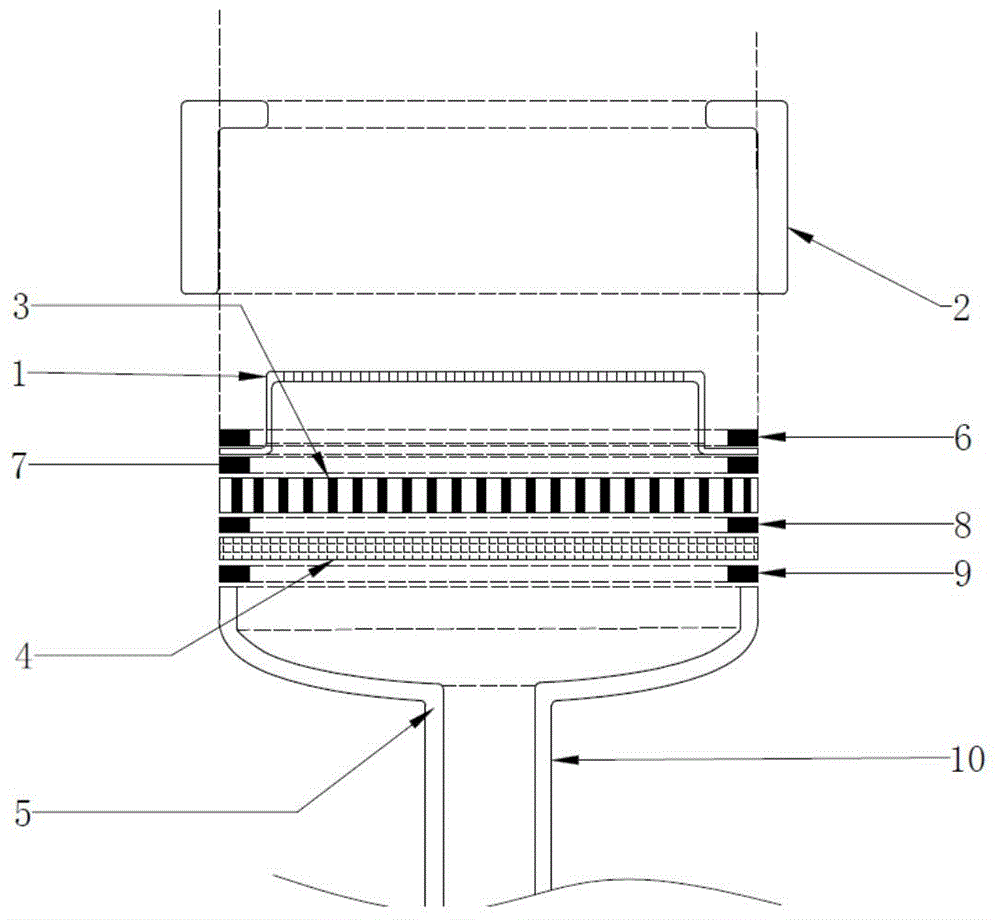

[0048] (2) Conveying, filtering and distributing of raw liquid: adopt embedded spinneret, the heat preservation temperature of pipeline, filter and spinning assembly...

Embodiment 2

[0055] (1) Preparation of stock solution: Add acrylonitrile, ammonium itaconate and methacrylic acid to the polymerization kettle, then add initiator and dimethyl sulfoxide, react at a temperature of 60°C for 24 hours, and then remove untreated The reacted monomer and the bubbles generated by the reaction are used to obtain the spinning dope, the initiator is azobisisobutyronitrile, the mass ratio of acrylonitrile and comonomer is 90:10, and the mass percentage of the initiator in the total monomer is 0.25 %, the total monomer concentration is 25%, and the high-performance polyacrylonitrile copolymer spinning dope is obtained through filtration. The temperature of silk stock solution is 60°C.

[0056] (2) Conveying, filtering and distributing of the raw liquid: the embedded spinneret is adopted, and the heat preservation temperature of the pipeline, filter and spinning assembly is 65°C; 10, the filter mesh of the first filter layer is 1600, and the filter mesh of the second f...

Embodiment 3

[0063] (1) Stock solution preparation: add acrylonitrile and itaconic acid to the polymerization kettle, then add initiator and dimethyl sulfoxide, react at a temperature of 65°C for 30 hours, and then remove unreacted monomers and Bubbles generated by the reaction were used to obtain the spinning dope, the initiator was azobisisobutyronitrile, the mass ratio of acrylonitrile and comonomer was 95:5, the mass percentage of the initiator accounting for the total monomer was 0.2%, and the total monomer The concentration of the polyacrylonitrile copolymer is 20%, and the high-performance polyacrylonitrile copolymer spinning stock solution is obtained through filtration. The spinning stock solution has a particle weight of 80,000, a molecular weight distribution of 15, a viscosity of 60 Pa·S at 60°C, and a spinning stock solution temperature of 60°C. ℃.

[0064] (2) Conveying, filtering and distributing of the stock solution: the embedded spinneret is adopted, and the heat preserva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com