A test method for slag resistance of refractory materials

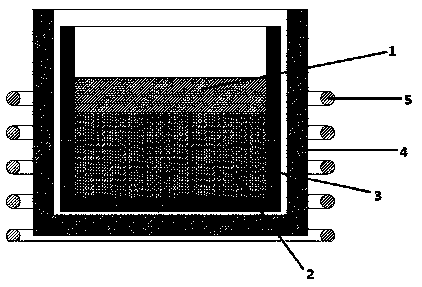

A technology of refractory materials and test methods, applied in the field of refractory materials, can solve the problems of low reproducibility of test conditions, large test temperature fluctuations, inability to simulate and reflect slag erosion, etc., and achieve good slag resistance and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

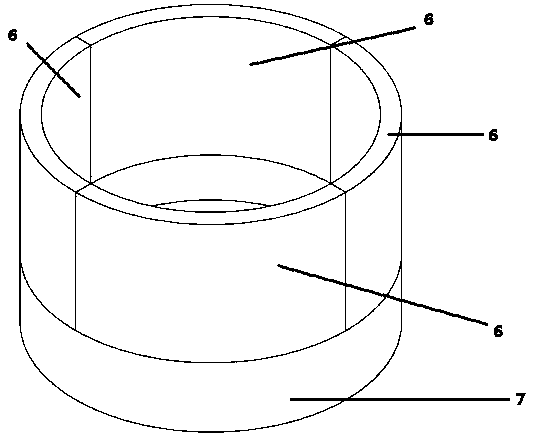

[0030] Embodiment 1: as figure 2 As shown, the corundum (Al 2 o 3 ≥99%), corundum-mullite (Al 2 o 3 =95%, SiO 2 =5%), mullite (Al 2 o 3 =72%, SiO 2 =28%), corundum-spinel (Al 2 o 3 =95%, MgO=5%) samples of 4 kinds of materials are spliced into the reaction zone 6 of the sample crucible; the inner diameter of the sample crucible is 150mm, the side wall thickness is 20mm, the bottom thickness is 35mm, and the inner cavity depth is 192mm; the material of the iron zone 7 is Corundum-mullite (Al 2 o 3 =95%, SiO 2 =5%), the material of reaction zone 6 is corundum (Al 2 o 3 ≥99%), corundum-mullite (Al 2 o 3 =95%, SiO 2 =5%), mullite (Al 2 o 3 =72%, SiO 2 =28%), corundum-spinel (Al 2 o 3 =95%, MgO=5%), the four materials divide the circumference into equal parts; the boundary line between the iron-containing area and the slag-containing area is located on the circumference of the crucible at a distance of 128mm from the upper edge of the crucible; Insulated fo...

Embodiment 2

[0041] Embodiment 2: by corundum (Al 2 o 3 ≥99%), high chromium (Cr 2 o 3 =90%, Al 2 o 3 =10%), chrome corundum (Cr 2 o 3 =10%, Al 2 o 3 =90%) samples of 3 kinds of materials were prepared into a sample crucible which was spliced and combined based on the materials of these samples to be tested. The inner diameter of the sample crucible is 200mm, the thickness of the side wall is 30mm, the thickness of the bottom is 50mm, and the depth of the inner cavity is 400mm; 2 o 3 ≥99%), the upper end of the side wall of the crucible (named the slag-holding area) is corundum (Al 2 o 3 ≥99%), high chromium (Cr 2 o 3 =90%, Al 2 o 3 =10%), chrome corundum (Cr 2 o 3 =10%, Al 2 o 3 =90%), the three materials divide the circumference into equal parts; the boundary line between the iron-containing area and the slag-containing area is located on the circumference of the crucible at a distance of 267mm from the upper edge of the crucible; the crucible is formed by ramming, a...

Embodiment 3

[0052] Embodiment 3: corundum-spinel-ZrO 2 (Al 2 o 3 =87%, MgO=8%, ZrO 2 =4%), Al 2 o 3- ZrO 2 (Al 2 o 3 =94%, ZrO 2 =5%) samples of two kinds of materials were prepared into a sample crucible which was spliced and combined based on the materials of these samples to be tested. The inner diameter of the sample crucible is 100mm, the thickness of the side wall is 10mm, the thickness of the bottom is 25mm, and the depth of the inner cavity is 120mm; 2 o 3- ZrO 2 (Al 2 o 3 =94%, ZrO 2 =5%), the upper end of the crucible side wall (named as the slag holding area) is made of corundum-spinel-ZrO 2 (Al 2 o 3 =87%, MgO=8%, ZrO 2 =4%), Al 2 o 3- ZrO 2 (Al 2 o 3 =94%, ZrO 2=5%) two materials divide the circumference equally; the boundary line between the iron-containing area and the slag-containing area is located on the circumference of the crucible at a distance of 80 mm from the upper edge of the crucible; the crucible is formed by vibratory casting and fired ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com