Epitaxial structure of light emitting diode and epitaxial growth method therefor

A technology of light-emitting diodes and epitaxial growth, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as poor anti-static ability of LEDs, and achieve the effect of improving anti-static ability, slowing defects and dislocations, and reducing leakage channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

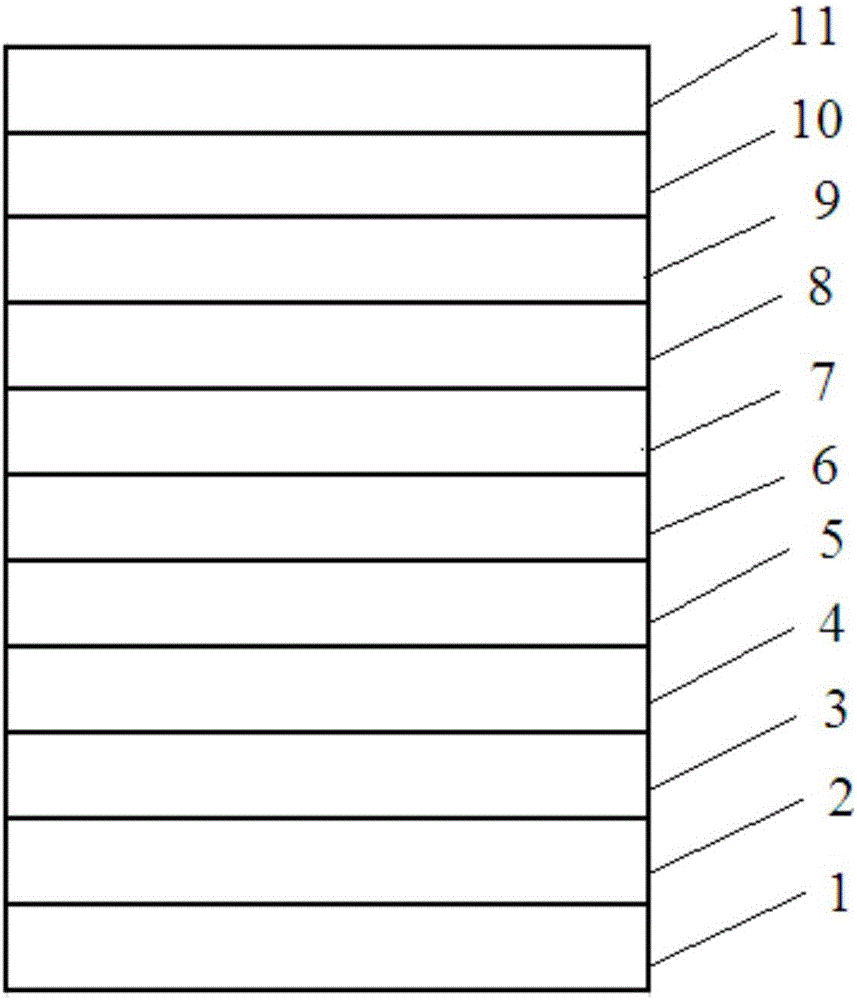

[0037] An embodiment of the present invention provides an epitaxial structure of a light emitting diode, see figure 1 , the epitaxial structure includes a sapphire substrate 1, and Al stacked sequentially on the sapphire substrate 1 x Ga 1-x N buffer layer 2, GaN buffer layer 3, undoped GaN layer 4, N-type GaN layer 5, shallow well layer 6, multiple quantum well layer 7, low-temperature P-type GaN layer 8, P-type AlGaN electron blocking layer 9, high temperature For the P-type GaN layer 10 and the P-type GaN contact layer 11, 0.3≦x≦0.8.

[0038] In this embodiment, both the shallow well layer 6 and the multiple quantum well layer 7 include alternately stacked InGaN layers and GaN layers.

[0039] Optionally, Al x Ga 1-x The thickness of the N buffer layer 2 may be 2-8 nm. When Al x Ga 1-x When the thickness of the N buffer layer 2 is less than 2nm, it cannot effectively alleviate the Al 2 o 3 Lattice mismatch between GaN and GaN; when Al x Ga 1-x When the thickness ...

Embodiment 2

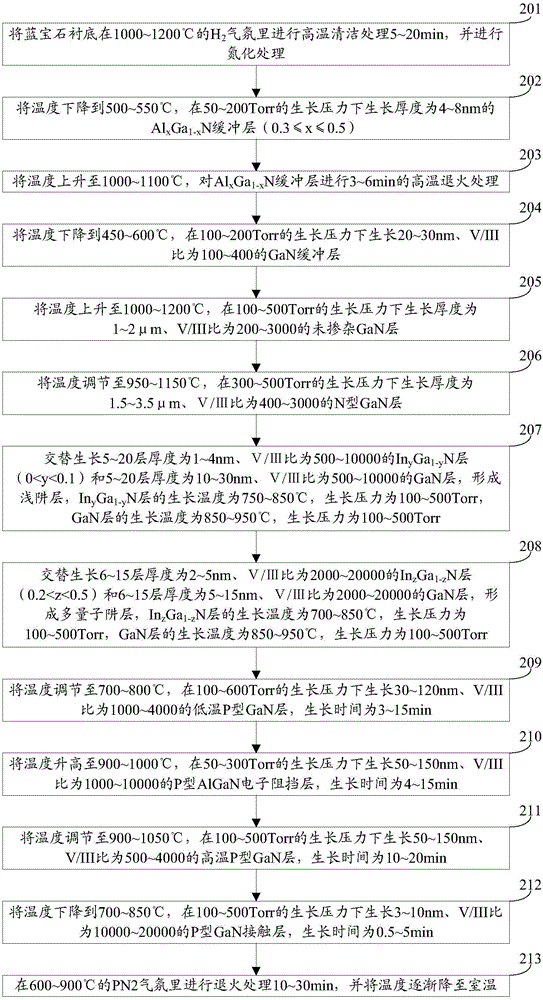

[0054] An embodiment of the present invention provides an epitaxial growth method of a light emitting diode, which is a specific implementation of the epitaxial structure of a light emitting diode provided in Embodiment 1, see figure 2 , the epitaxial growth method includes:

[0055] Step 201: Put the sapphire substrate in H at 1000-1200°C 2 Carry out high-temperature cleaning treatment in the atmosphere for 5-20 minutes, and carry out nitriding treatment.

[0056] Step 202: Lower the temperature to 500-550° C., and grow Al with a thickness of 4-8 nm under a growth pressure of 50-200 Torr x Ga 1-x N buffer layer (0.3≤x≤0.5).

[0057] Step 203: raise the temperature to 1000-1100°C, for Al x Ga 1-x The N buffer layer is subjected to high-temperature annealing treatment for 3-6 minutes.

[0058] Step 204: Lower the temperature to 450-600° C., and grow a GaN buffer layer with a thickness of 20-30 nm and a V / III ratio of 100-400 under a growth pressure of 100-200 Torr.

[0...

Embodiment 3

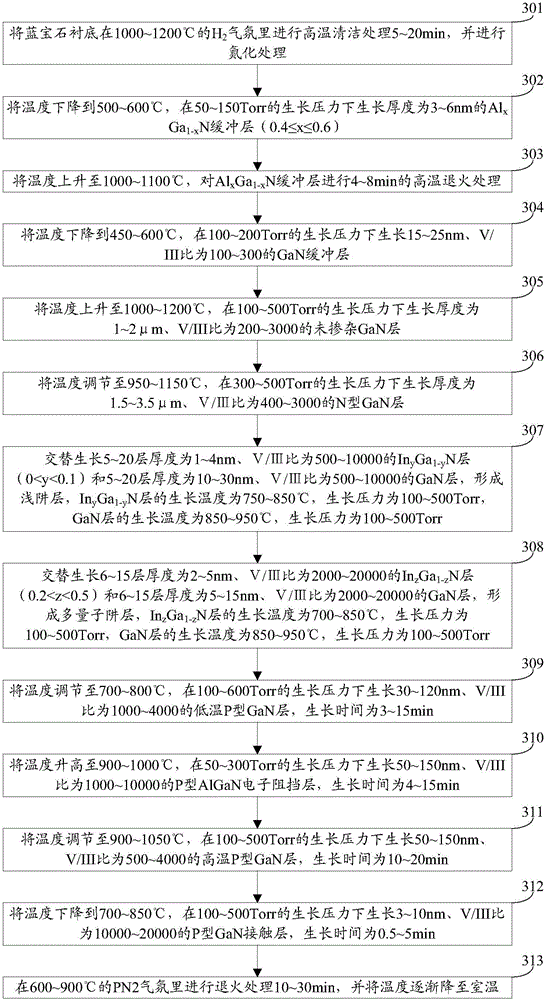

[0070] An embodiment of the present invention provides an epitaxial growth method of a light-emitting diode, which is another specific realization of the epitaxial structure of a light-emitting diode provided in Embodiment 1, see image 3 , the epitaxial growth method includes:

[0071] Step 301: Put the sapphire substrate in H at 1000-1200°C 2 Carry out high-temperature cleaning treatment in the atmosphere for 5-20 minutes, and carry out nitriding treatment.

[0072] Step 302: Lower the temperature to 500-600° C., and grow Al with a thickness of 3-6 nm under a growth pressure of 50-150 Torr x Ga 1-x N buffer layer (0.4≤x≤0.6).

[0073] Step 303: Raise the temperature to 1000-1100°C, for Al x Ga 1-x The N buffer layer is subjected to high-temperature annealing treatment for 4-8 minutes.

[0074] Step 304: Lower the temperature to 450-600° C., and grow a GaN buffer layer with a thickness of 15-25 nm and a V / III ratio of 100-300 under a growth pressure of 100-200 Torr.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com