Poly-dopamine coated nano-micro powder and preparation method thereof

A polydopamine, nano-micro technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problem of lack of general research on polydopamine coating various powders, and achieve high repeatability, simple operation and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

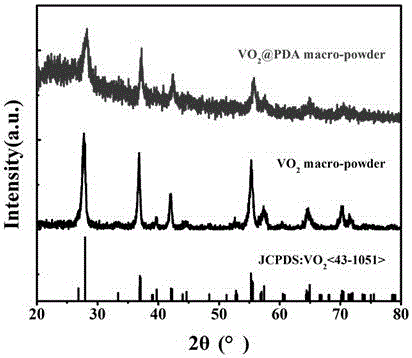

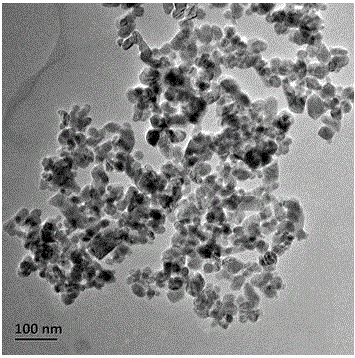

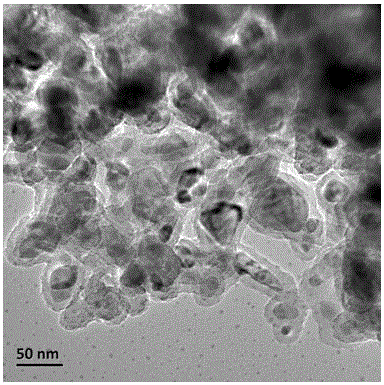

[0031] 1.3g vanadium pentoxide (V 2 o 5 , Wako Pure Chemicals Co., Ltd.) was added into 40mL of hydrogen peroxide 10% by weight aqueous solution, and continued to stir for 2-4 hours to obtain a brown transparent sol; in the above sol, slowly drop 5% by weight of hydrazine hydrate ( N 2 h 4 -H 2 (2) aqueous solution, measure the pH value of the solution simultaneously, until the pH value reaches between 4-5 (the pH value is 4.2 in this experiment) stop dripping; Can add tungstic acid as required to make the W:V element content ratio in the solution between Within 5%" Put the above solution in a hydrothermal reaction kettle and heat it at 270°C for 24 hours; After cooling the reaction kettle, take out the product, filter, wash, and dry to obtain a single rutile crystal with excellent thermochromic properties Phase vanadium dioxide (VO 2 (R)) nano powder.

[0032] Take the prepared VO 2 Add 0.5g of powder into 400mL deionized water, stir for 2 hours; 2 A certain amount of...

Embodiment 2

[0035] Take 0.5g of commercially available cesium-doped tungsten oxide nano-micropowder, add it into 400mL deionized water, and stir for 2 hours; add a certain amount of buffer to the cesium-doped tungsten oxide aqueous solution, and then adjust the pH of the solution to 5 with acid / alkali; Dissolve dopamine hydrochloride in deionized water to a concentration of 0.2 g / mL. Take 5 mL of the above-prepared dopamine hydrochloride aqueous solution and slowly add it dropwise into the cesium-doped tungsten oxide aqueous solution; seal the seal and stir for 24 hours to obtain a polydopamine-coated cesium-doped tungsten oxide nano-micro composite with a large specific volume and excellent dispersibility Powder.

[0036] The crystallinity and morphology of the powder were characterized by XRD and TEM. The results show that the polydopamine is uniformly coated on the surface of the cesium-doped tungsten oxide nano-micropowder.

Embodiment 3

[0038]Take 0.5 g of commercially available alumina nano-micropowder, add it into 400 mL of deionized water, and stir for 2 hours; add a certain amount of buffer to the alumina aqueous solution, and then adjust the pH of the solution to 8 with acid / alkali; In deionized water, the concentration is 0.2g / mL. Take 5 mL of the above-prepared dopamine hydrochloride aqueous solution and slowly add it dropwise into the alumina aqueous solution; seal the seal and stir for 24 hours to obtain polydopamine-coated alumina nano-micro composite powder with extremely large specific volume and excellent dispersibility.

[0039] The crystallinity and morphology of the powder were characterized by XRD and TEM. The results show that polydopamine is evenly coated on the surface of alumina nano-micropowder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com