High-performance all-solid-state lithium-ion battery and preparation method thereof

A lithium-ion battery and all-solid-state technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problems of daily use of large-capacity power batteries and the difficulty in satisfying the electrochemical performance of all-solid-state lithium-ion batteries. , to achieve the effects of high energy density, high safety, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

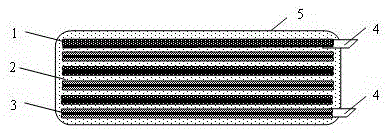

Image

Examples

Embodiment 1

[0040] Lithium iron phosphate, lithium superionic conductor Li 10 GeP2 S 12 , conductive carbon, high molecular polymer PEO according to the mass ratio of 80%: 10%: 5%: 5%, respectively weighed 240g, 30g, 15g, 15g and vacuum stirred in 540g benzene to form a positive electrode mixed slurry, which was coated on the treated on the aluminum foil, dried and pressed into a positive sheet.

[0041] The mixture of molten lithium metal and hot silicone oil at 200°C is stirred at a high speed of 20,000r / min to form a uniform emulsion, then cooled to room temperature, filtered, washed, and dried naturally to obtain lithium powder with a particle size of 23-58 μm; According to the theoretical capacity of lithium, 5% excess negative electrode capacity was used for matching, and 9.88g lithium powder and 1.85g lithium superionic conductor Li 10 GeP 2 S 12 , 0.62g of high molecular polymer PEO was vacuum stirred in 22.23g of benzene to form a negative electrode mixed slurry, which was co...

Embodiment 2

[0045] The binary material lithium nickel cobalt oxide, lithium superionic conductor Li 10 SnP 2 S 12 , conductive carbon, polymer PAN according to the mass ratio of 80%: 8%: 8%: 4%, respectively weighed 240g, 24g, 24g, 12g and vacuum stirred in 300g acetonitrile to form a positive electrode mixed slurry, which was coated on the treated on the aluminum foil, dried and pressed into a positive sheet.

[0046] The mixture of molten lithium metal and hot silicone oil at 200°C is stirred at a high speed of 25,000r / min to form a uniform emulsion, then cooled to room temperature, filtered, washed, and dried naturally to obtain lithium powder with a particle size of 21-46 μm; According to the theoretical capacity of lithium, 5% excess negative electrode capacity was used for matching, and 10.58g of lithium powder and 1.49g of lithium superionic conductor Li 10 SnP 2 S 12 1. 0.37g of high molecular polymer PAN was vacuum stirred in 12.45g of acetonitrile to form a negative electro...

Embodiment 3

[0050] The ternary nickel cobalt lithium manganese oxide, lithium superionic conductor Li 10 GeP 2 S 12 , conductive carbon, high molecular polymer PEO according to the mass ratio of 80%: 5%: 10%: 5%, respectively weighed 240g, 15g, 30g, 15g and vacuum stirred in 450g dimethylformamide to form a positive electrode mixed slurry, coated Spread it on the treated aluminum foil, dry it, and press it into a positive electrode sheet.

[0051] The mixture of molten lithium metal and hot silicone oil at 250°C is stirred at a high speed of 25,000r / min to form a uniform emulsion, then cooled to room temperature, filtered, washed, and dried naturally to obtain lithium powder with a particle size of 19-40μm; According to the theoretical capacity of lithium, 5% excess negative electrode capacity was used for matching, and 10.54g of lithium powder and 1.24g of lithium superionic conductor Li 10 GeP 2 S 12 1. 0.62g of high molecular polymer PEO was vacuum stirred in 18.60g of dimethylfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com