Method for preparing catalyst for hydrogenolysis of biodiesel by-product glycerinum to produce 1,3-propylene glycol

A technology of biodiesel and catalyst, which is applied in the field of environmental chemical industry, can solve the problems of metal/carrier assembly, metal loss, etc., and achieve the effect of realizing waste recycling and low metal loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

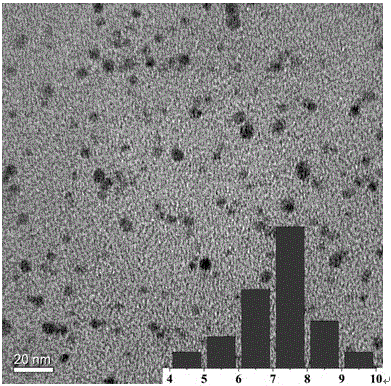

[0032] (1) Preparation of platinum nanoparticles: a total of 3mL PVP-ethylene glycol solution (0.375mol / L) and 1.3mL chloroplatinic acid-ethylene glycol (6.25×10 -2 mol / L) solution was slowly added to the condensing reflux device. The mixture was continued to reflux at 200°C for 5 minutes. 12.9 mL of acetone was added to the mixture of platinum nanoparticles for centrifugation, and the obtained platinum nanoparticles were redispersed in 8.2 mL of PVP-ethanol solution.

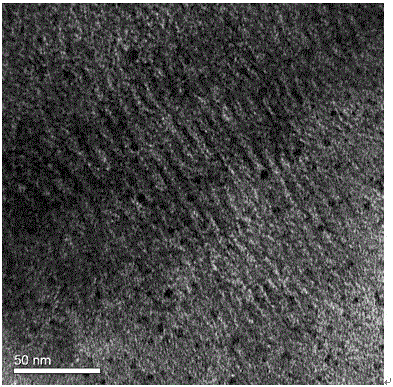

[0033] (2) Assembly of platinum nanoparticles / mesoporous alumina: Dissolve 1.26g triblock copolymer F108 in 30mL ethanol solution containing 0.8mol / L hydrochloric acid and 1.33mol / L glacial acetic acid, and stir the mixture ultrasonically for 15 minutes A homogeneous solution was obtained. Then, 2.46 g of aluminum sec-butoxide and 6.5 mL of the platinum nanoparticle-ethanol solution obtained in step (1) were added to the homogeneous solution, and stirred ultrasonically for 15 minutes to obtain a sol mixture. ...

Embodiment 2

[0036] To the mensuration of catalyst saturated water absorption in embodiment 1: get 5 grams of PtNPs / Al 2 o 3 Catalyst, add deionized water 15mL, let stand for 10 minutes, centrifuge, measure the filtrate volume to be 9.5mL, calculate the saturated water absorption rate of the catalyst to be 1.1mL / g.

Embodiment 3

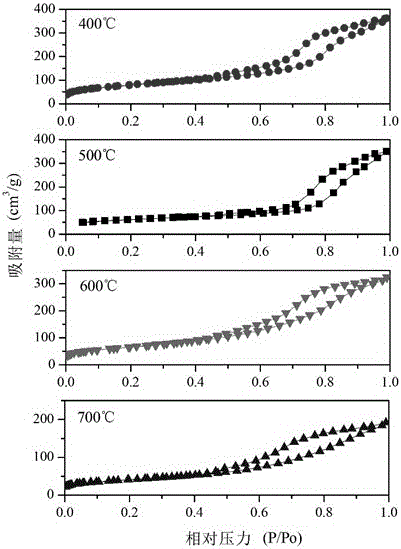

[0038] Determination of the optimum template stripping temperature in Example 1: Dissolve 1.26g of triblock copolymer F108 in 30mL of ethanol solution containing 0.8mol / L hydrochloric acid and 1.33mol / L glacial acetic acid, and stir the mixture ultrasonically for 15 minutes to obtain homogeneous solution. Then, 2.46 g of aluminum sec-butoxide and 6.5 mL of the platinum nanoparticle-ethanol solution obtained in step (1) were added to the homogeneous solution, and stirred ultrasonically for 15 minutes to obtain a sol mixture. Finally the resulting sol was transferred to a large surface area petri dish. The molar ratio of each substance in the final reaction system is: Pt / F108 / hydrochloric acid / glacial acetic acid / ethanol / aluminum sec-butoxide=0.008 / 0.01 / 2 / 4 / 65 / 1. Alcoholysis of aluminum sec-butoxide and self-assembly of template agent F108 were carried out at a temperature of 40°C, and transferred to an oven at 65°C for 24 hours after 3 hours. Finally, the samples were fired i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com