Preparation method of copper silicon catalyst for hydrogenation of dimethyl oxalate to ethylene glycol

A technology of dimethyl oxalate and ethylene glycol, which is applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problem that it is difficult to produce copper phyllosilicate species, achieve high conversion rate, high active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

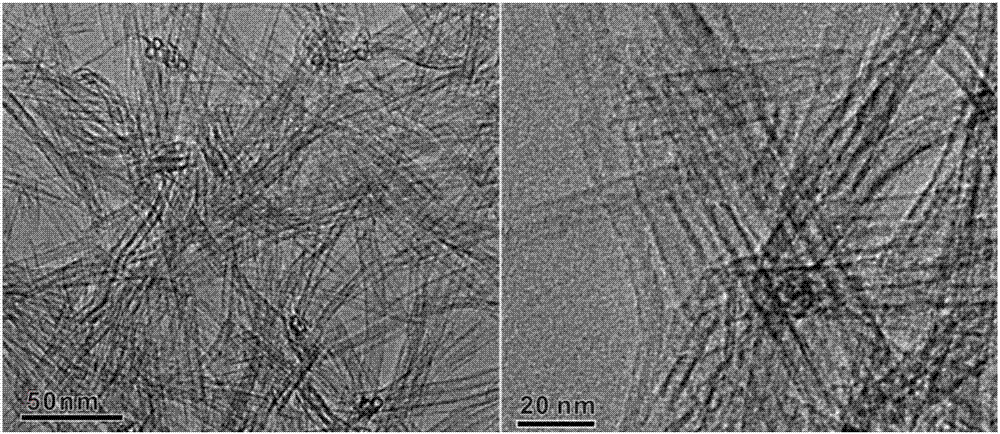

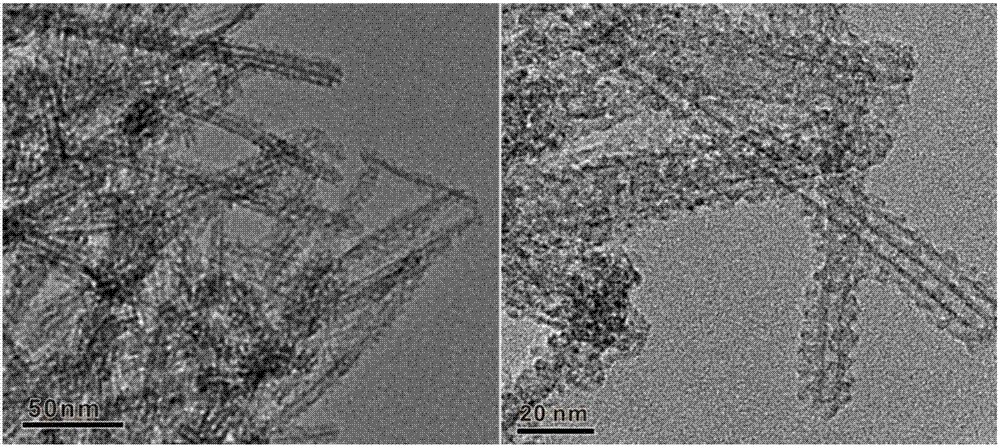

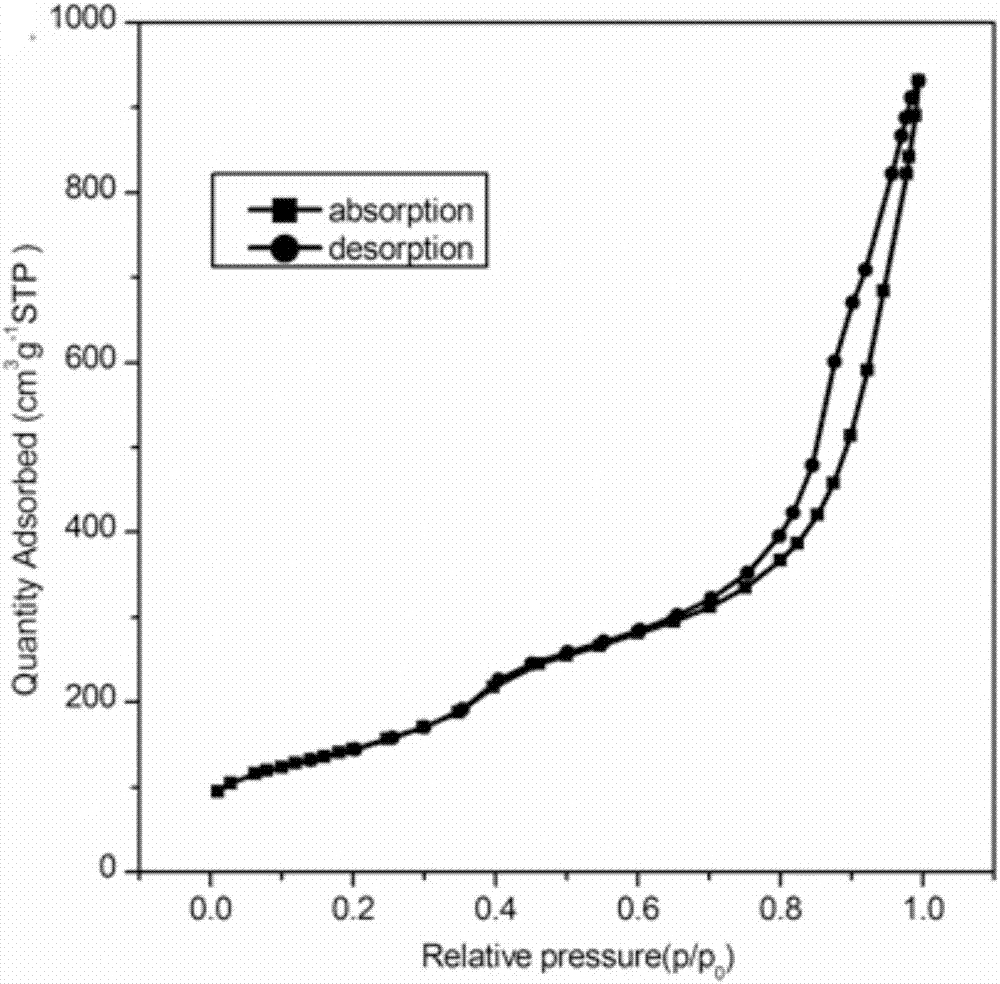

Embodiment 1

[0035] (1) The silica sol is added to water to prepare a 1.5g / L silica sol solution, and the silica sol dispersion is obtained after 10-30 minutes of ultrasound.

[0036] (2) Add ammonia to the 0.08mol / L copper chloride aqueous solution, and control the concentration of ammonia to 5mol / L to form a copper ammonia complex ion solution, stir for 10-30min, then add ammonium chloride, and control the chlorination The concentration of ammonium is 0.15 mol / L to finally obtain a mixed solution of copper ammonia complex ions.

[0037] (3) The silica sol dispersion obtained in step (1) is slowly added dropwise to the cupramide ion mixed solution obtained in step (2), and a mixed solution of silica sol and cupramide ion is obtained after stirring for 30 minutes.

[0038] (4) Transfer the mixed solution obtained in step (3) to a closed container, place it in a constant temperature environment of 150° C., and keep it for 96 hours.

[0039] (5) The blue precipitate obtained in step (4) is repeatedl...

Embodiment 2

[0044] (1) The silica sol is added to water to prepare a 1.5g / L silica sol solution, and the silica sol dispersion is obtained after 10-30 minutes of ultrasound.

[0045] (2) Add ammonia to the 0.04mol / L copper chloride aqueous solution, and control the concentration of ammonia to 2.5mol / L to form a copper ammonia complex ion solution, stir for 10-30min, then add ammonium chloride, and control the chlorine The concentration of ammonium chloride is 0.15 mol / L to finally obtain a mixed solution of copper ammonia complex ions.

[0046] (3) The silica sol dispersion obtained in step (1) is slowly added dropwise to the cupramide ion mixed solution obtained in step (2), and a mixed solution of silica sol and cupramide ion is obtained after stirring for 30 minutes.

[0047] (4) Transfer the mixed solution obtained in step (3) to a closed container, place it in a constant temperature environment of 170° C., and keep it for 72 hours.

[0048] (5) The blue precipitate obtained in step (4) is re...

Embodiment 3

[0053] (1) The silica sol is added to water to prepare a 1.5g / L silica sol solution, and the silica sol dispersion is obtained after 10-30 minutes of ultrasound.

[0054] (2) Add ammonia to the 0.02mol / L copper chloride aqueous solution, and control the concentration of the ammonia to 10mol / L to form a copper ammonia complex ion solution, stir for 10-30min, then add ammonium chloride, and control the chlorination The concentration of ammonium is 0.15 mol / L to finally obtain a mixed solution of copper ammonia complex ions.

[0055] (3) The silica sol dispersion obtained in step (1) is slowly added dropwise to the cupramide ion mixed solution obtained in step (2), and a mixed solution of silica sol and cupramide ion is obtained after stirring for 30 minutes.

[0056] (4) Transfer the mixed solution obtained in step (3) to a closed container, place it in a constant temperature environment at 190°C, and keep it for 48 hours.

[0057] (5) The blue precipitate obtained in step (4) is repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com