Hypsizigus marmoreus culture medium and culture method

A technology for the mushroom and the culture medium, which is applied in the field of the culture medium of the mushroom, can solve the problems of limited application, refractory degradation, and inability to fully utilize medicinal residues, and achieves the effects of simple cultivation method, low cost and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

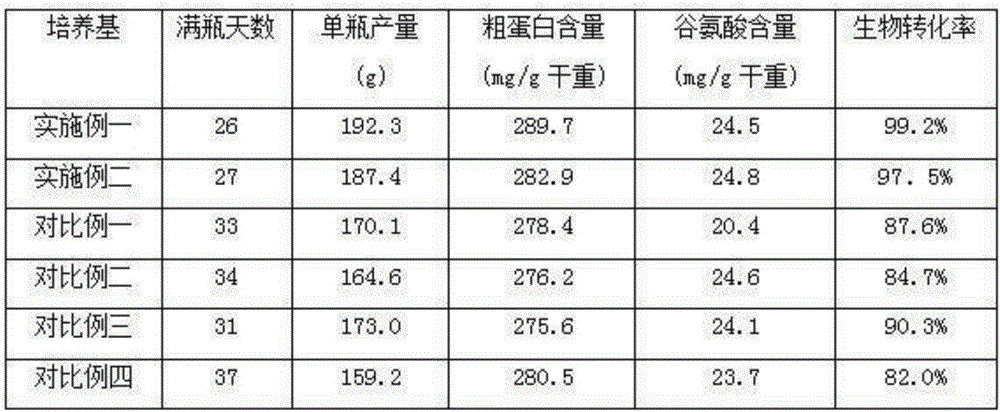

Examples

Embodiment

[0030] The substratum of embodiment one Shiji mushroom

[0031] The components and mass percentages of the culture medium of Shijiji mushroom are as follows: 45% of corncobs, 10% of rice bran, 5% of schisandra dregs, 15% of salvia miltiorrhiza, 7% of soybean hulls, 16% of wheat bran, and 1.5% of shell powder , Lime 0.5%.

[0032] Preparation method: Weigh the above raw materials, crush corncobs to a particle size of 4-7mm, extrude the salvia miltiorrhiza root to a particle size of 4-6mm, and crush the schisandra fruit residues to a particle size of 1-3mm. Mix and serve.

Embodiment 2

[0033] The substratum of embodiment two true mushrooms

[0034] The components and mass percentages of the culture medium of Shijiji mushroom are as follows: 42% of corncobs, 8% of rice bran, 6% of Schisandra chinensis dregs, 18% of salvia miltiorrhiza, 5% of soybean hulls, 18% of wheat bran, and 2% of shell powder , Lime 1%.

[0035] Preparation method: Weigh the above raw materials, crush corncobs to a particle size of 4-7mm, extrude the salvia miltiorrhiza root to a particle size of 4-6mm, and crush the schisandra fruit residues to a particle size of 1-3mm. Mix and serve.

Embodiment 3

[0036] The medium of embodiment three true mushrooms

[0037] The components and mass percentages of the culture medium of Shijiji mushroom are as follows: 46% of corncobs, 12% of rice bran, 4% of Schisandra chinensis dregs, 12% of Danshen dregs, 8% of soybean hulls, 16% of wheat bran, and 1% of shell powder , Lime 1%.

[0038] Preparation method: Weigh the above raw materials, crush corncobs to a particle size of 4-7mm, extrude the salvia miltiorrhiza root to a particle size of 4-6mm, and crush the schisandra fruit residues to a particle size of 1-3mm. Mix and serve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com