Nylon toughener, and preparation method and application thereof

A toughening agent and nylon technology, applied in the field of toughening nylon preparation, can solve the problems of reducing the efficiency of grafting polyolefins with polar monomers, reducing the mechanical properties of nylon materials, and the adverse effects of extrusion processes, and reducing cross-linking. and degradation side reactions, reducing the decline of mechanical properties, and excellent processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

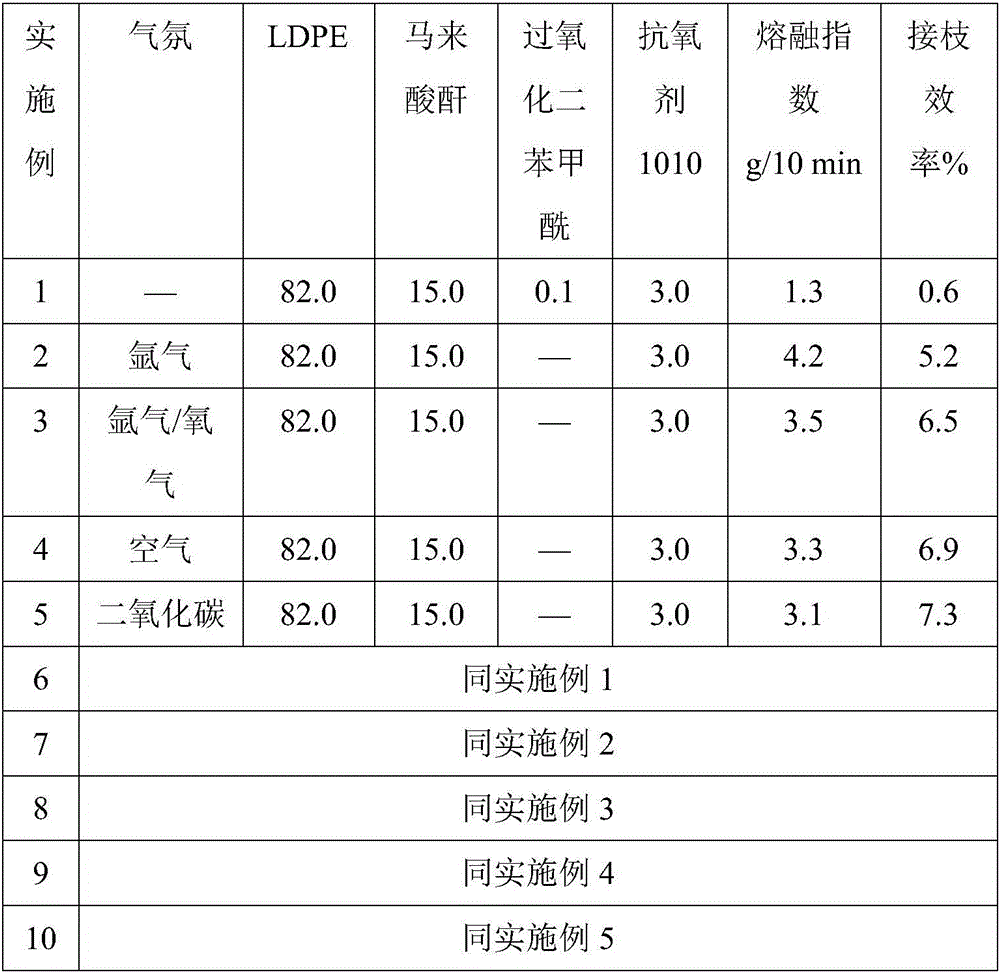

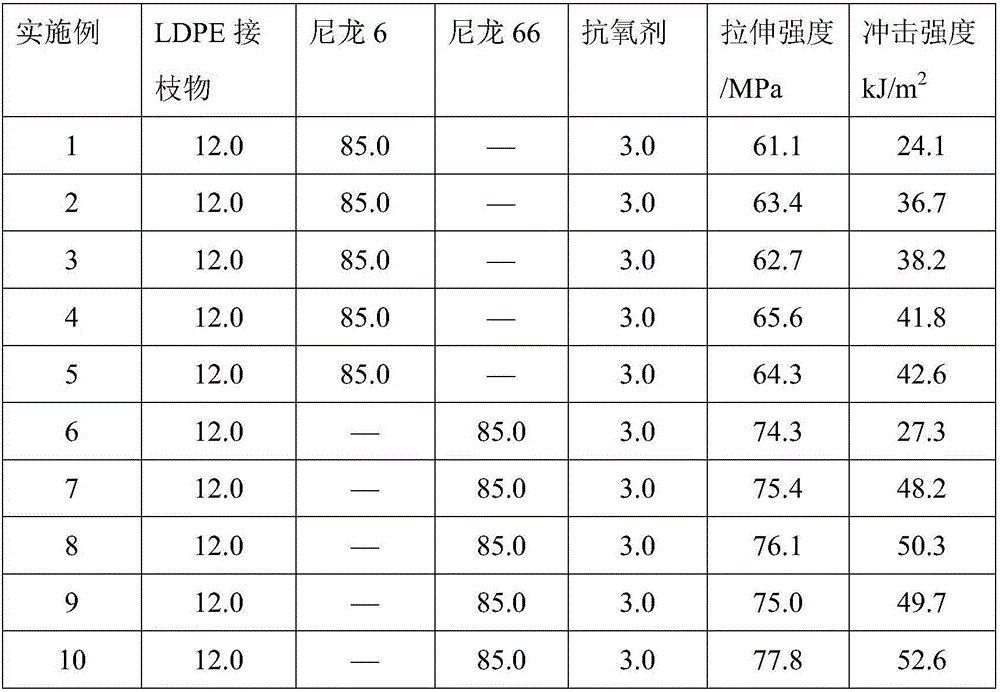

[0041] Embodiment 1: comparative example

[0042] Weigh 81.9 parts of LDPE (parts by weight, the same below, Yanshan Petrochemical LD160, melt index 5.0g / 10min), 15.0 parts of maleic anhydride, 0.1 part of dibenzoyl peroxide, 10103.0 parts of antioxidant, and mix maleic anhydride Dissolve in 10.0 parts of absolute ethanol, dissolve dibenzoyl peroxide in 5.0 parts of absolute ethanol, mix LDPE, dibenzoyl peroxide solution, maleic anhydride solution, and antioxidant 1010 in a high-speed mixer Mix evenly, add the above mixture into the hopper of the extruder, the temperature of each zone of the extruder is between 150°C and 180°C, the speed of the main screw is 60 rpm, the speed of the feeding screw is 10 rpm, and the extruded product is drawn, Cool, dry, and pelletize to obtain maleic anhydride grafted LDPE particles. Weigh 685.0 parts of nylon, 12.0 parts of maleic anhydride grafted LDPE, and 10103.0 parts of antioxidant, mix them evenly in a high-speed mixer, put them into th...

Embodiment 2

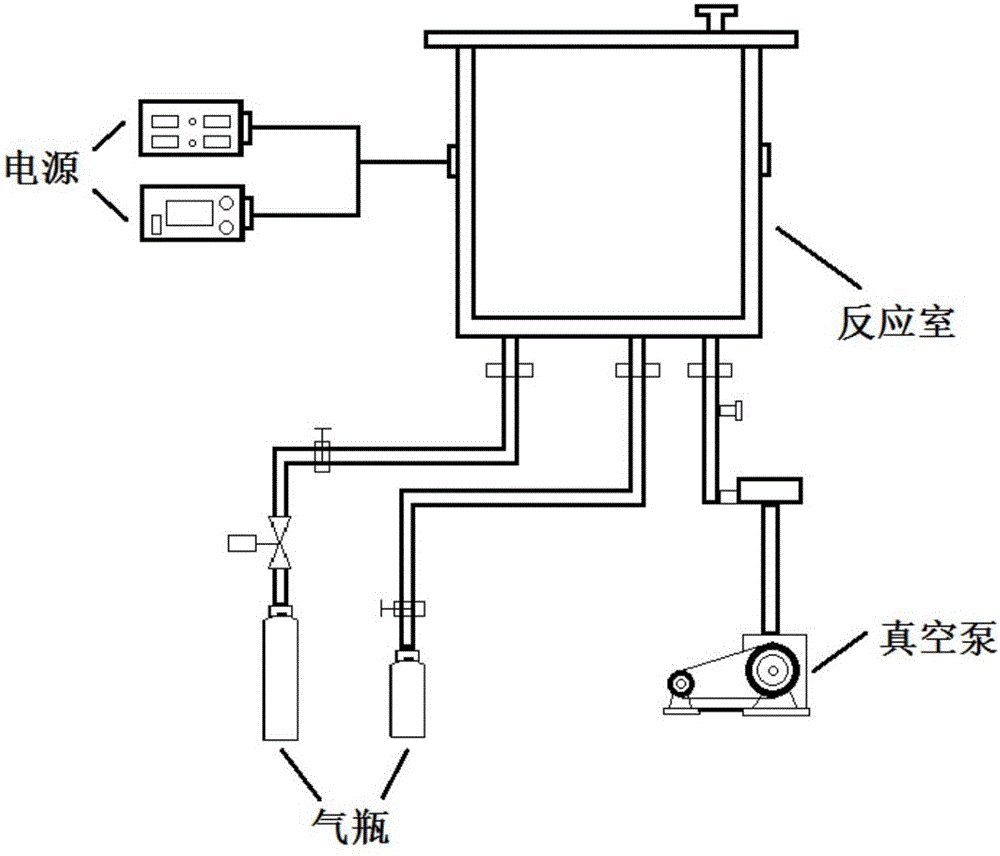

[0044] Weigh 82.0 parts of LDPE (parts by weight, the same below, Yanshan Petrochemical LD160, melt index 5.0 g / 10min), 15.0 parts of maleic anhydride, and 10103.0 parts of antioxidant. Put LDPE in the plasma reaction device, after vacuuming, pass in argon gas, the gas pressure is 100Pa, the radio frequency discharge power is 20W, and the discharge time is 10min, then the surface modified LDPE, adipic acid, and antioxidant 1010 are mixed for 30min, Put the mixture into the hopper of the extruder, and react under the conditions of 150-180°C, the speed of the main screw is 60 rpm, and the speed of the feeding screw is 10 rpm, and the extruded product is drawn, cooled, dried, cut granules to obtain maleic anhydride grafted LDPE granules. Weigh 685.0 parts of nylon, 12.0 parts of maleic anhydride grafted LDPE, and 10103.0 parts of antioxidant, mix them evenly in a high-speed mixer, put them into the hopper of the extruder, and set the temperature between 200°C and 260°C at the mai...

Embodiment 3

[0046] Weigh 82.0 parts of LDPE (parts by weight, the same below, Yanshan Petrochemical LD160, melt index 5.0 g / 10min), 15.0 parts of maleic anhydride, and 10103.0 parts of antioxidant. Put LDPE in the plasma reaction device, after vacuuming, pass in argon / oxygen (volume ratio 4 / 1) mixed gas, the gas pressure is 100Pa, the radio frequency discharge power is 20W, and the discharge time is 10min, then the surface modified LDPE, Mix adipic acid and antioxidant 1010 for 30 minutes, put the mixture into the hopper of the extruder, and react under the conditions of 150-180 ° C, the main screw speed is 60 rpm, and the feeding screw speed is 10 rpm. The extruded product is drawn, cooled, dried and pelletized to obtain maleic anhydride grafted LDPE pellets. Weigh 685.0 parts of nylon, 12.0 parts of maleic anhydride grafted LDPE, and 10103.0 parts of antioxidant, mix them evenly in a high-speed mixer, put them into the hopper of the extruder, and set the temperature between 200°C and 26...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com