Maleic anhydride grafted polypropylene composition and preparation method thereof

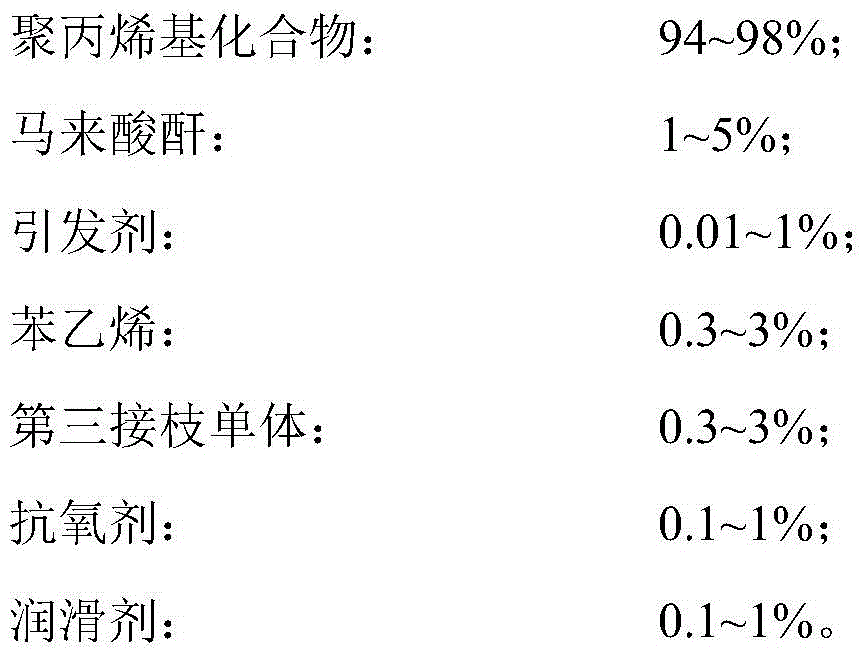

A technology of grafting polypropylene and maleic anhydride, applied in the field of maleic anhydride grafted polypropylene composition and its preparation, can solve the problem of high residual amount of maleic anhydride monomer, difficulty in satisfying compatibilizer and melt viscoelasticity Poor and other problems, to achieve the effect of increasing the grafting rate of the product, excellent viscoelasticity, and improving the viscoelasticity of the melt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

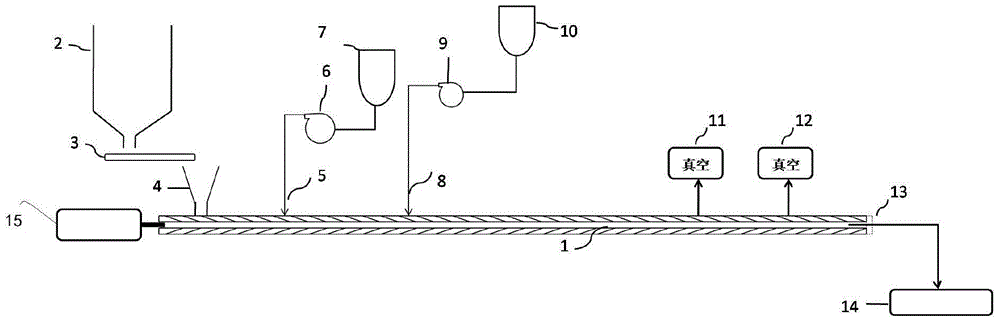

Method used

Image

Examples

Embodiment 1

[0034] First, 9.56 kg of polypropylene powder (PP045, Zhenhai Refining & Chemical) was uniformly mixed with 400 g of maleic anhydride in acetone solution by spraying, and then 10 g of antioxidant 1010, 10 g of antioxidant 168 and 20g calcium stearate, add from main feed after mixing by high-speed mixer; Initiator dicumyl peroxide (DCP) content is that the white oil solution of 10% adds from second side feeding port. Adjust the addition of the main feeding port and the second side feeding port to be 30kg / h and 600g / h respectively.

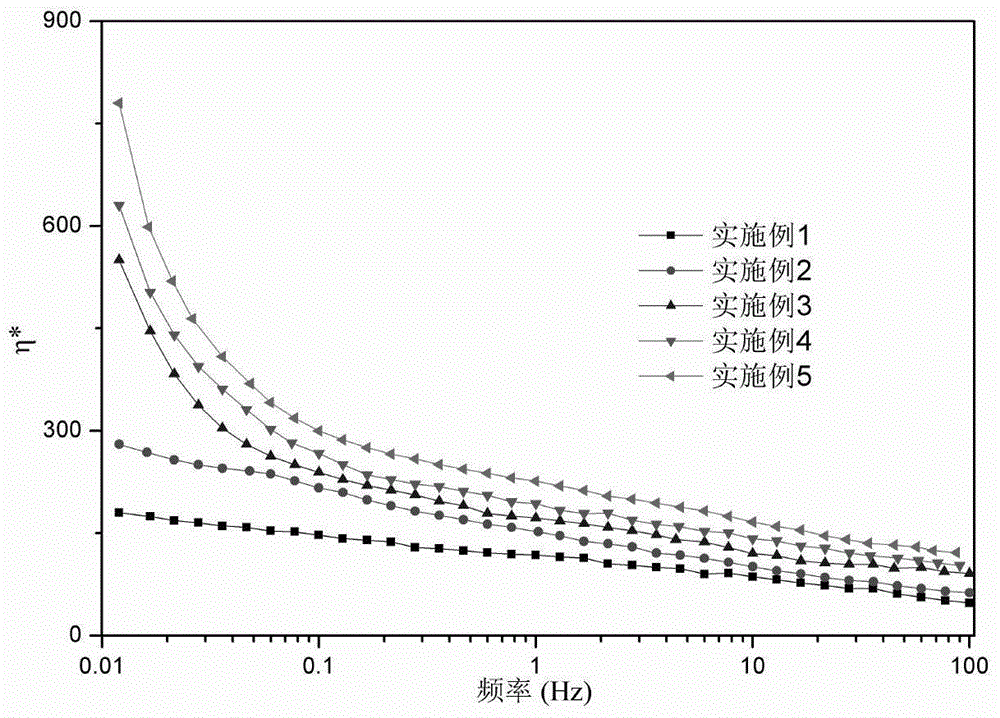

[0035] In this plan, the temperature of the co-rotating twin-screw extruder is 140°C, 160°C, 180°C, 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, 190°C. The aspect ratio of the twin-screw is 48, the screw speed is 250rpm, and the residence time of the melt in the screw is about 60s. The relevant test results of the prepared samples are shown in Table 1, and the rheological data are as follows figure 2 shown.

Embodiment 2

[0037] First, 9.56kg polypropylene powder is uniformly mixed with the acetone solution that is dissolved with 400g maleic anhydride by spraying, then add 10g of antioxidant 1010, 10g of antioxidant 168 and 20g calcium stearate, pass After the high-speed mixer mixes evenly, add it from the main feed; add styrene from the first side feed port. Adjust the main feed, the initiator dicumyl peroxide (DCP) content of 10% white oil solution is added from the second side feed port, adjust the main feed, the first side feed port and the second side feed The addition amount of mouth is 30kg / h, 600g / h and 300g / h respectively.

[0038] In this plan, the temperature of the co-rotating twin-screw extruder is 140°C, 160°C, 180°C, 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, 190°C. The aspect ratio of the twin-screw is 48, the screw speed is 250rpm, and the residence time of the melt in the screw is about 60s. The relevant test results of the obtained samples are shown in Table 1,...

Embodiment 3

[0040]First, 9.56kg polypropylene powder is uniformly mixed with the acetone solution that is dissolved with 400g maleic anhydride by spraying, then add 10g of antioxidant 1010, 10g of antioxidant 168 and 20g calcium stearate, pass After the high-speed mixer mixes uniformly, it is added from the main feed; 10% white oil solution is added from the second side feed port, and the addition of the main feed, the first side feed port and the second side feed port is adjusted to be 30kg / h, 600g / h and 600g / h respectively.

[0041] In this plan, the temperature of the co-rotating twin-screw extruder is 140°C, 160°C, 180°C, 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, 190°C. The aspect ratio of the twin-screw is 48, the screw speed is 250rpm, and the residence time of the melt in the screw is about 60s. The relevant test results of the obtained samples are shown in Table 1, and the rheological data are as follows: figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com